Coupled processing method of waste water in chemical industry plant area

A treatment method and technology of a chemical plant, applied in chemical instruments and methods, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc. Complicated components and other issues, to achieve the effect of enhancing the effect of flocculation and filtration, reducing the content of toxic and harmful substances, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

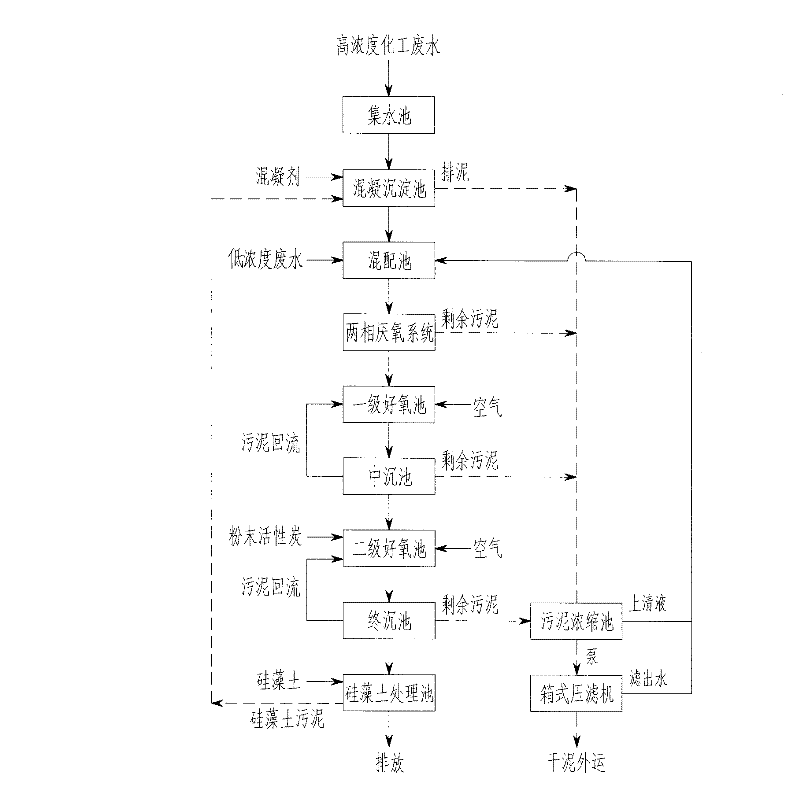

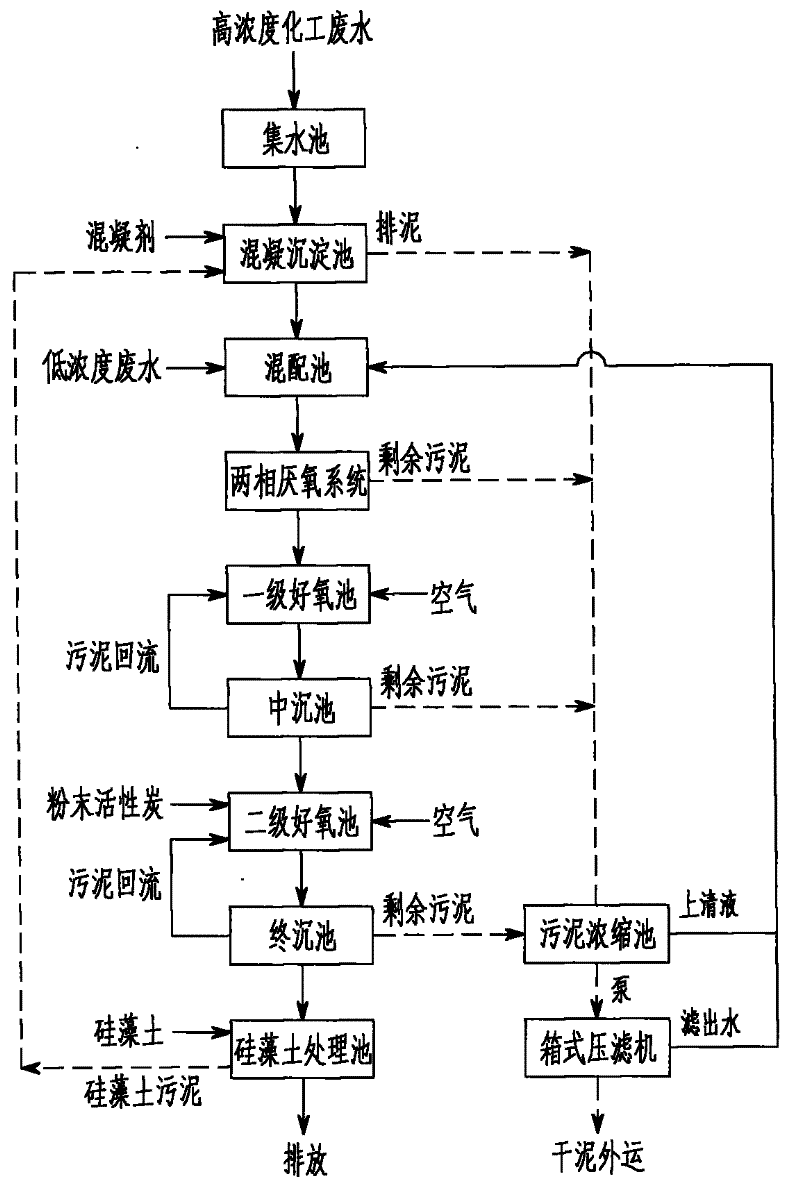

Method used

Image

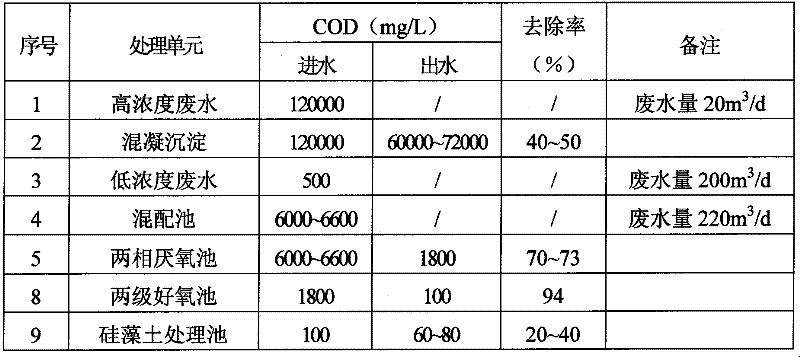

Examples

Embodiment 1

[0032] In a chemical company, a total of 3 high-concentration wastewater discharges.

[0033] One comes from the high boiling point solvent MADE (dibasic acid ester mixture) production workshop. The solvent MADE is produced from succinic acid, glutaric acid, adipic acid and methanol esterification reaction under the catalysis of nitric acid to produce mixed fat. The mixed fat neutralization section is divided into The water phase is discharged as wastewater, and its main components are nitrate, methanol, succinic acid, glutaric acid, adipic acid and mixed fats (dimethyl succinate, dimethyl glutarate, dimethyl adipate ester), copper ions, iron ions and other organic impurities, the COD is as high as 120000mg / L.

[0034] The second stream is the regular kettle washing water for paint production. The volume of waste water in this stream is relatively small, and the COD is about 60,000 mg / L.

[0035] The third stream comes from the alkyd resin workshop. The wastewater mainly cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com