Water vapor permeance resistant silicone sealant and manufacture method thereof

A technology of silicone sealant and steam, applied in the direction of chemical instruments and methods, other chemical processes, etc., to achieve the effect of not harsh process requirements and equipment, simple process, and non-yellowing appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

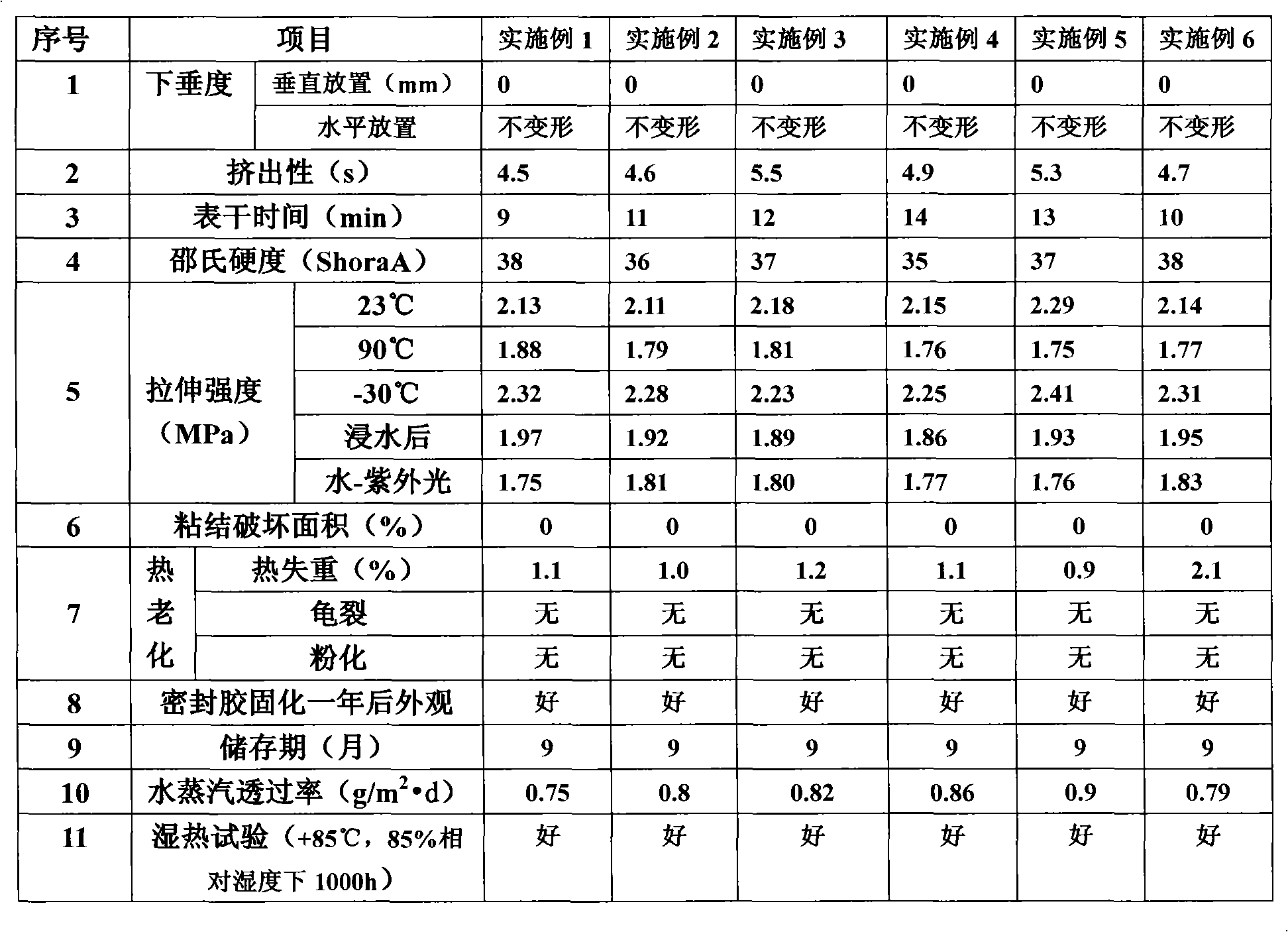

Examples

Embodiment 1

[0031] A) prepare the base material, α, ω-dihydroxypolydimethylsiloxane 100 parts, methyl methacrylate 10 parts and preferably by the chemical composition of Changshu Institute of Technology, Jiangsu Province, China according to the weight ratio or weighing parts The brand LGHC-A type cadmium telluride mixed catalyst developed with the School of Materials Engineering and sold to the outside world is 0.5 parts of the catalyst A defined in the present invention, which is added to the vacuum kneader for kneading. The temperature is controlled at 120°C, the kneading time is controlled at 120min, and 110.5 parts of the base material are obtained;

[0032] B) To prepare the sealant, first prepare 110.5 parts of the base material obtained in step A) in parts by weight, polydimethylsiloxane with a viscosity of 0.5 to 20 Pa.s terminated by trimethoxysiloxy and at 25°C 50 parts of oxane, 50 parts of magnesium hydroxide modified by fatty acid, 60 parts of aluminum hydroxide modified by f...

Embodiment 2

[0034] A) Preparation of the base material, 100 parts of α, ω-dihydroxypolydimethylsiloxane, butyl acrylate, hydroxyethyl acrylate and 2-ethylhexyl acrylate by weight or parts by weight The three are altogether 11 parts according to the ratio of 4: 4: 3 (weight ratio), and the trade mark that is preferably developed by the School of Chemistry and Materials Engineering, Changshu Institute of Technology, Jiangsu Province, China and sold externally is the LGHC-A type cadmium telluride mixed catalyst, which is defined in the present invention. Add 0.6 parts of catalyst A to a vacuum kneader for kneading, the vacuum degree of the vacuum kneader is controlled to be 0.09MPa, the kneading temperature is controlled to be 110°C, and the kneading time is controlled to be 110min to obtain 111.6 parts of base material;

[0035] B) To prepare the sealant, 111.6 parts of the base material obtained in step A) is prepared in parts by weight, which is terminated by dimethoxysiloxy and has a visc...

Embodiment 3

[0037] A) Prepare the base material, mix 100 parts of α, ω-dihydroxypolydimethylsiloxane, methyl acrylate, ethyl acrylate, butyl acrylate and hydroxyethyl acrylate in parts by weight or parts by weight Those according to 3: 2: 4: 3 ratio (weight ratio) add up to 12 parts and are preferably developed by the School of Chemistry and Materials Engineering of Changshu Institute of Technology, Jiangsu Province, China and the brand that is sold externally is the LGHC-A type cadmium telluride mixed catalyst, which is the invention. Add 0.7 parts of the defined catalyst A into a vacuum kneader and knead. The vacuum degree of the vacuum kneader is controlled at 0.07 MPa, the kneading temperature is controlled at 115° C., and the kneading time is controlled at 130 minutes to obtain 112.7 parts of base material;

[0038] B) To prepare the sealant, firstly, 112.7 parts of the base material obtained in step A), polydimethylsiloxane terminated by dimethylmethoxysiloxy and having a viscosity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com