Attapulgite clay quantum dot nano-composite fluorescent material and preparation method thereof

A nano-composite and fluorescent material technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of instability of thioglycolic acid and liposomes, decrease of fluorescence intensity, hindering biological application research, etc., and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the attapulgite quantum dot nanocomposite fluorescent material of the present invention comprises the following steps:

[0018] a. Add nano attapulgite to the aqueous solution of metal ion salt, stir magnetically for 1-60h at 20-80°C, centrifuge the solid, wash with deionized water, and dry to obtain attapulgite / metal ions,

[0019] b. Take attapulgite / metal ion, react it with an anion source at 20-80° C. for 1-60h, centrifuge the solid, wash, and dry to obtain attapulgite quantum dot nanocomposite fluorescent material.

[0020] The metal ion salt described in step a is zinc acetate, zinc chloride or cadmium chloride.

[0021] The anion source described in step b is sodium hydroxide, sodium sulfide, hydrogen sulfide or thiourea.

Embodiment 1

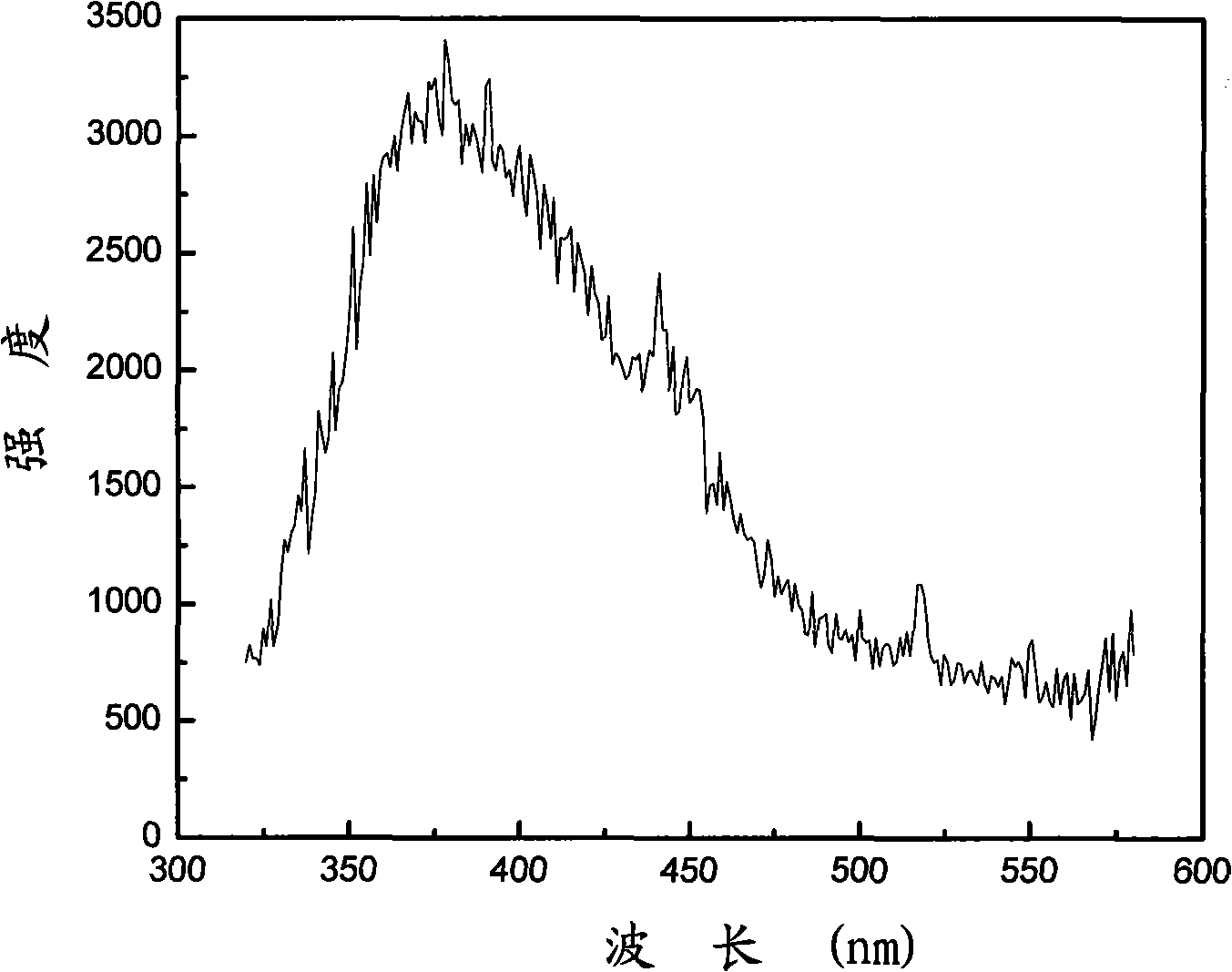

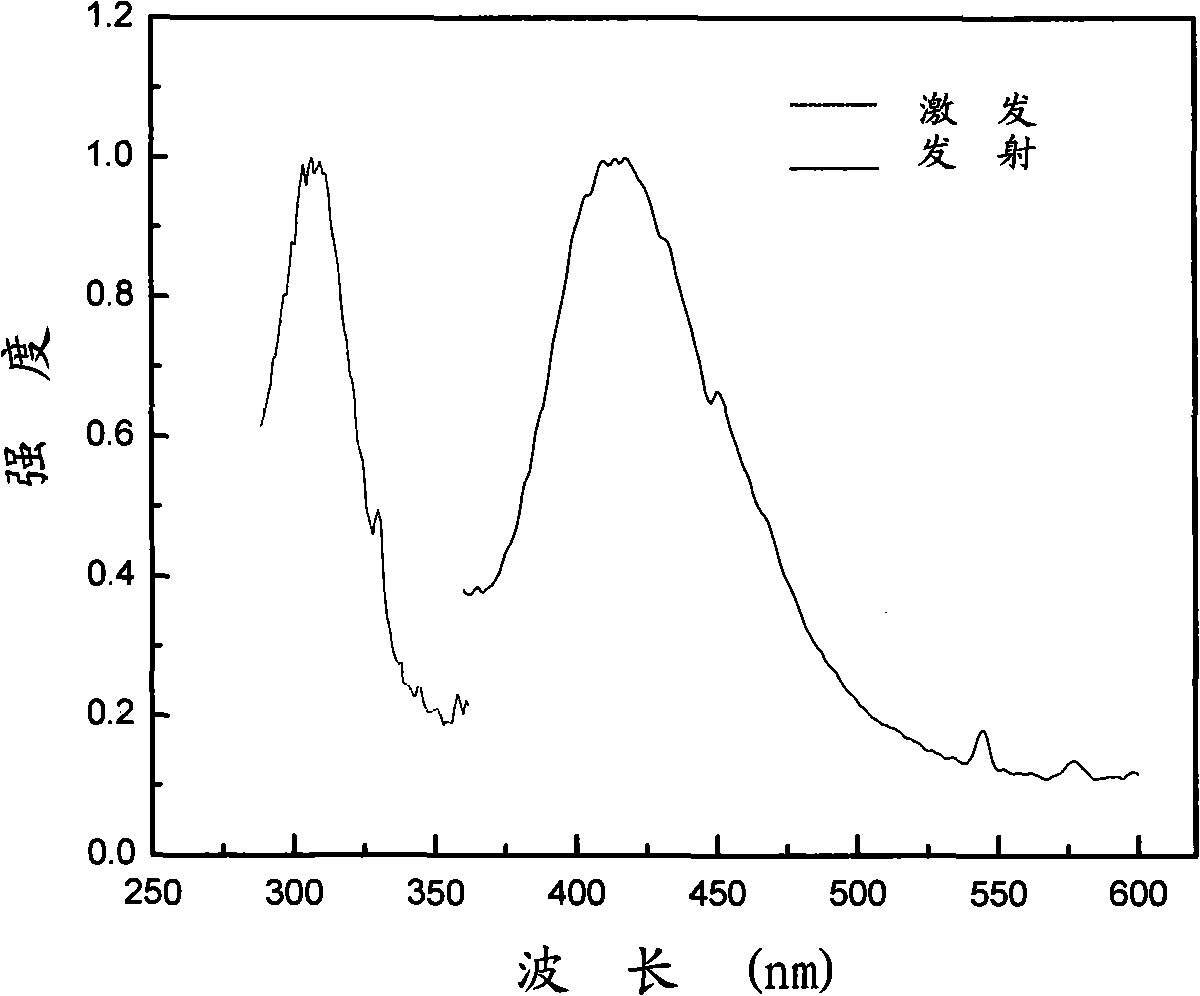

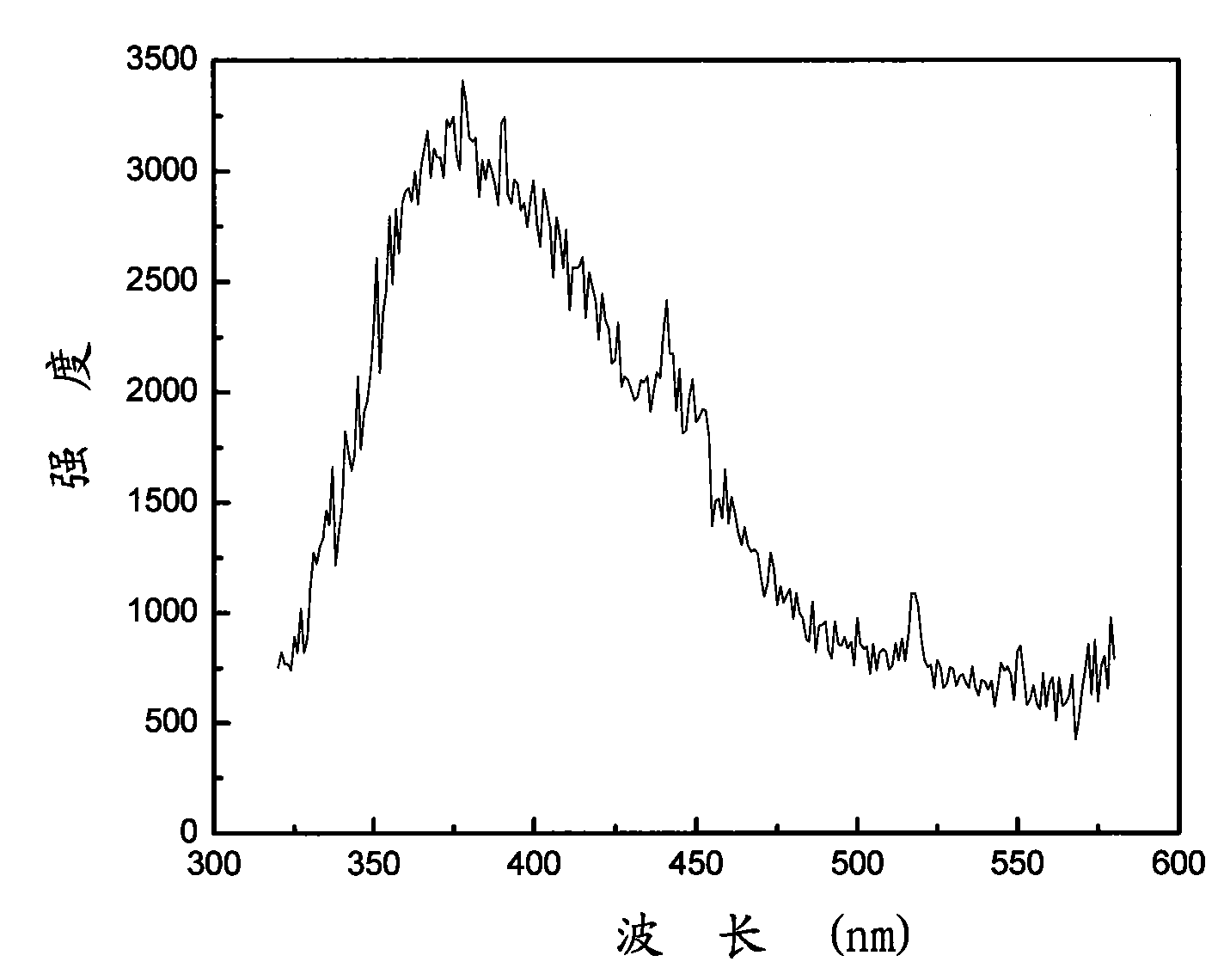

[0022] Embodiment 1: add 0.15g nano attapulgite in the reaction vessel, 30ml concentration is 0.1M Zn(CH 3 COO) 2 The solution was magnetically stirred at 30°C for 8h, the solid was centrifuged, washed with deionized water, and dried to obtain attapulgite / Zn 2+ . Take an appropriate amount of attapulgite / Zn 2+ , add 40 ml of 0.25 M NaOH solution in ethanol, and stir magnetically at 65 °C for 12 h. The solid was centrifuged, washed with ethanol, and dried to obtain attapulgite / ZnO composite nanomaterials.

Embodiment 2

[0023] Example 2: Add 0.13g of nano attapulgite to the reaction vessel, and 30ml of CdCl with a concentration of 0.1M 2 The solution was magnetically stirred at room temperature for 24h, the solid was centrifuged, washed with deionized water, and dried to obtain attapulgite / Cd 2+ . To an appropriate amount of attapulgite / Cd 2+ Add 40ml of 0.25M Na 2 The ethanolic solution of S was magnetically stirred at room temperature for 24 h. After the reaction, the solid was centrifugally washed until the pH was neutral, and after drying, the attapulgite / CdS composite nanomaterial was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com