Soil and rock curing agent and manufacturing method thereof and road structure and manufacturing method thereof

A manufacturing method and curing agent technology, applied in chemical instruments and methods, roads, roads, etc., can solve the problems of increasing processing costs and transportation costs, high road construction costs, and inability to use pavement base layers, and reduce road construction. cost, good social and economic benefits, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

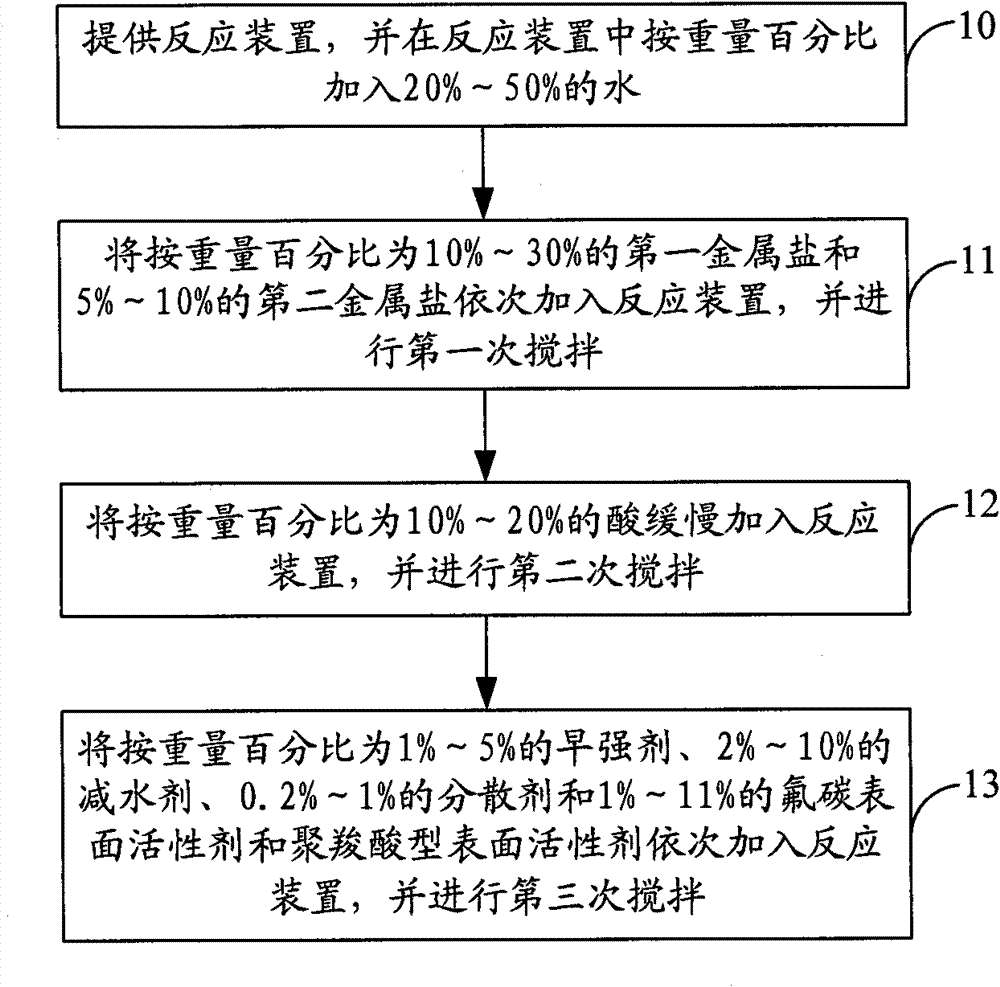

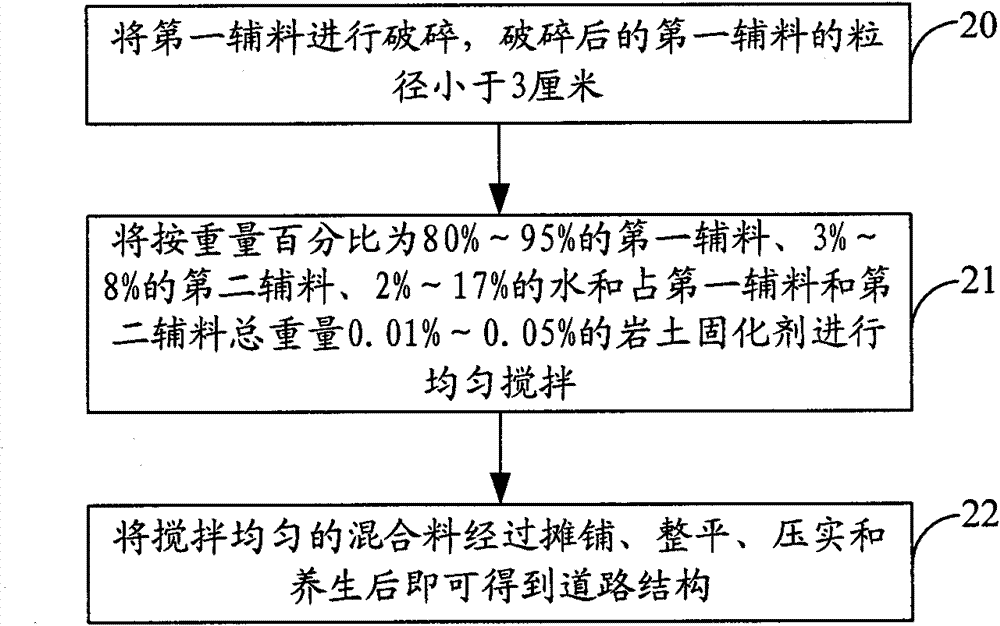

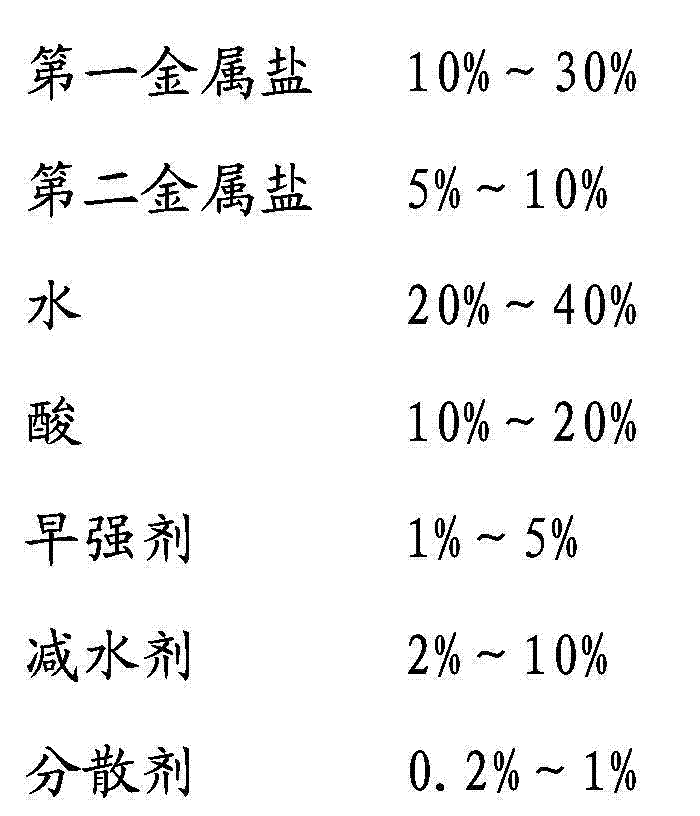

Method used

Image

Examples

Embodiment 1

[0055] First, after adding 350 kg of water to the reactor, open the reactor; secondly, add 80 kg of iron sulfate and 140 kg of sodium sulfate to the reactor in turn, and stir for 30 minutes; again, slowly add 180 kg of concentrated sulfuric acid Then, add 10 kilograms of DuPont FSN-100 fluorocarbon surfactant, 30 kilograms of triethanolamine, 80 kilograms of calcium lignosulfonate superplasticizer, 10 kilograms of ten Sodium dialkyl sulfate and 90 kg of TH-928 polycarboxylate high-performance water reducer were added to the reaction kettle in sequence, and stirred for 2 hours; finally, the geotechnical curing agent was obtained by exiting the kettle.

Embodiment 2

[0057] First, after adding 350 kg of water into the reactor, open the reactor; secondly, add 80 kg of ferric chloride and 210 kg of sodium chloride into the reactor in turn, and stir for 30 minutes; again, add 150 kg of concentrated Hydrochloric acid is slowly added in the reaction kettle and stirred for 30 minutes; then, 5 kilograms of DuPont FSN-100 fluorocarbon surfactant, 50 kilograms of triethylenepropanolamine, 100 kilograms of sodium lignosulfonate water reducer , 10 kg of polyvinyl alcohol and 200 kg of TH-928 polycarboxylate high-performance water reducer were added to the reaction kettle in turn, and stirred for 2 hours; finally, the geotechnical curing agent was obtained by exiting the kettle.

Embodiment 3

[0059] First, after adding 350 kg of water to the reactor, open the reactor; secondly, add 200 kg of ferric chloride and 70 kg of potassium sulfate to the reactor in turn, and stir for 30 minutes; again, add 150 kg of concentrated sulfuric acid Slowly add in the reaction kettle, and stir for 30 minutes; Then, 12 kilograms of FC-4430 fluorocarbon surfactant of 3M company, 48 kilograms of triethanolamine, 80 kilograms of aliphatic superplasticizer, 9 kilograms of six Sodium metaphosphate and 53 kg of TH-928 polycarboxylate high-performance water reducer are added to the reaction kettle in sequence, and stirred for 2 hours; finally, the rock soil curing agent can be obtained by taking out the kettle.

[0060] Most weathered rock-soil aggregates are negatively charged. When they are used to build road subgrades, under the action of pressure, weathered rock-soil aggregates approach a certain distance, which will generate mutual repulsion, resulting in a decrease in compaction. Betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com