Preparation method for high purity fish scale collagen

A technology of fish scale collagen and collagen, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as unstable product quality, low product purity, and large waste water discharge, and achieve acid saving Alkali soaking and cleaning steps, efficient separation effect, process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

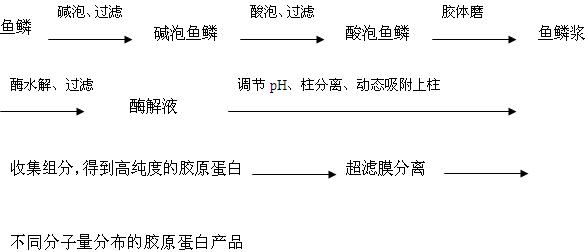

Method used

Image

Examples

Embodiment 1

[0018] Take 100 kg of washed fish scales, add 600 liters of 0.5% NaOH solution, and soak for 4 hours. Drain the lye and use it for the alkali soaking process of the next batch of fish scales. Add 800 liters of 0.5% acetic acid solution to the collected fish scale solids, pulverize them with a colloid mill, and grind them into fish scale jelly, that is, fish scale slurry. Adjust the pH with 10% acetic acid solution to achieve a final pH of 3.5. A two-step enzymatic hydrolysis process is adopted. The first step of enzymolysis uses pepsin, the amount of enzyme added is 0.8%, the pH value is adjusted to 3.0, the reaction temperature is 40°C, and the enzymolysis time is 8 hours; the second step of enzymolysis uses high-efficiency protease, and the amount of enzyme added is 0.7 %, adjust the pH value to 4.5, the reaction temperature is 40°C, and the enzymolysis time is 12 hours. The enzymatic hydrolysis product was centrifuged at 5000rpm for 10min, and the supernatant was collect...

Embodiment 2

[0021] Take 100 kg of washed fish scales, add 600 liters of 0.5% NaOH solution, and soak for 4 hours. Drain the lye and use it for the alkali soaking process of the next batch of fish scales. Add 800 liters of 0.5% citric acid solution to the fish scale solids, soak for 4 hours, add a colloid mill, and grind it into a jelly, that is, fish scale slurry. Add 10% citric acid solution to the fish scale slurry, mix thoroughly, and adjust the pH until the final pH reaches 3.5. Add 1.0% protease (pepsin, trypsin, papain, subtilisin or cathepsin, etc.), 35 ℃, under the condition of full stirring, enzymatic hydrolysis for 6h. The enzymatic hydrolysis product was centrifuged at 5000rpm for 10min, and the supernatant was collected, that is, the crude collagen extract.

[0022] Add 10% NaOH solution to the crude collagen extract collected above, and adjust the pH to 3.5. Flow through the cation exchange resin (10×100cm) at a flow rate of 1 times the bed volume / hour, and the volume of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com