Anaerobic-sequencing batch biofilm reactor-artificial wetland method for treating piggery wastewater

A sequencing batch type membrane biology and sequencing batch type biofilm technology are applied in chemical instruments and methods, animal husbandry wastewater treatment, water/sewage multi-stage treatment, etc. The problem of high content, to achieve the effect of reducing treatment costs, reducing floor space, and high sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

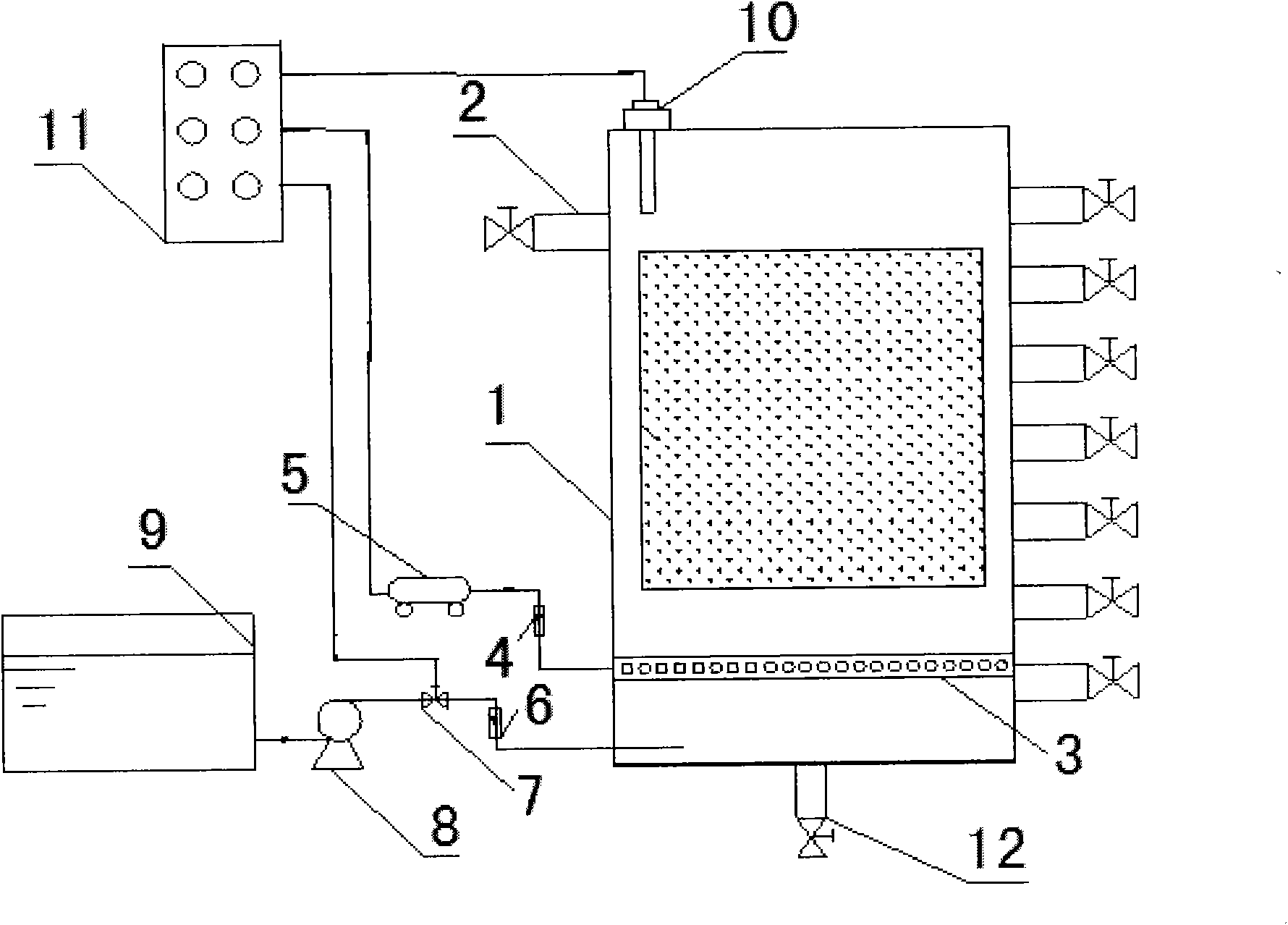

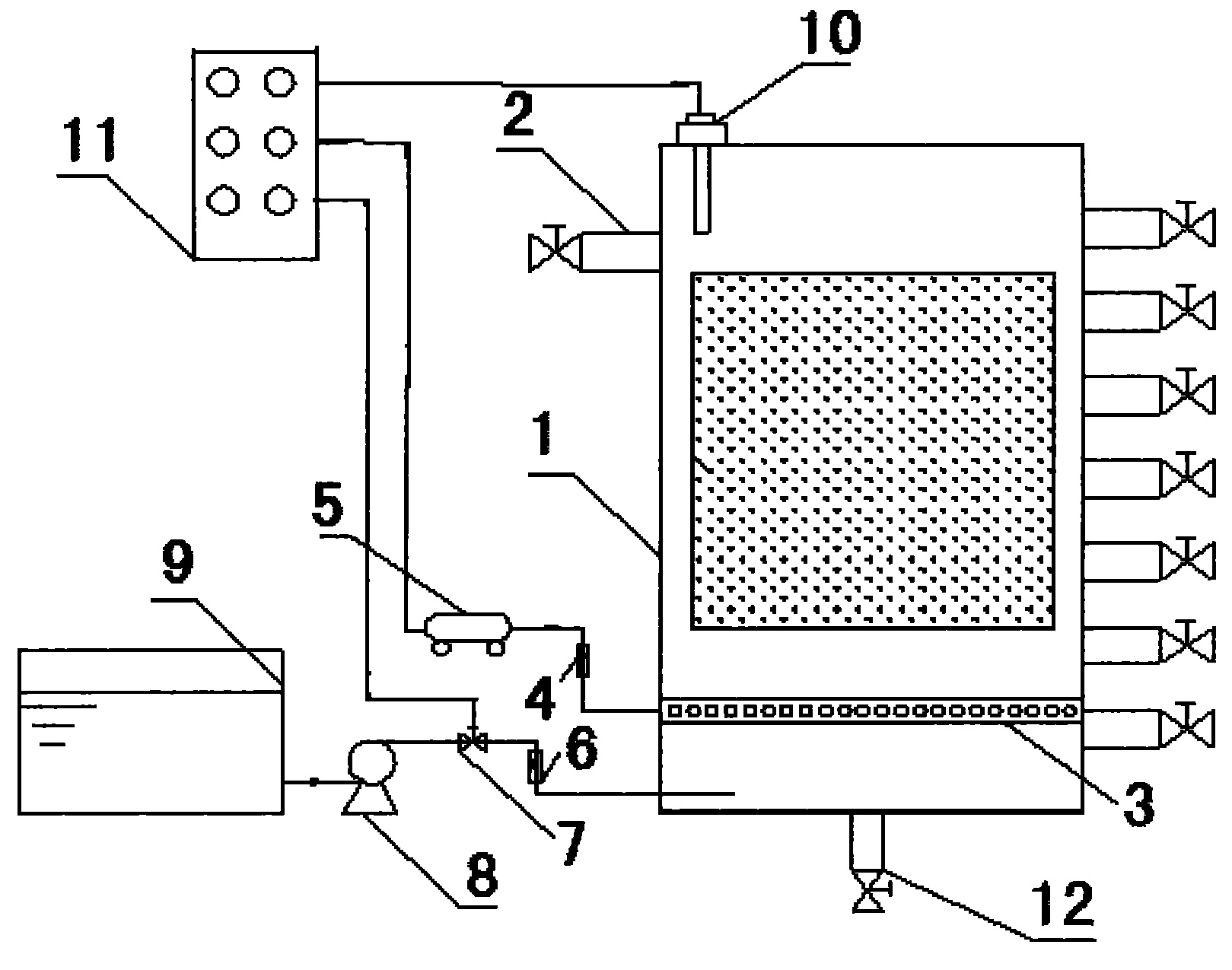

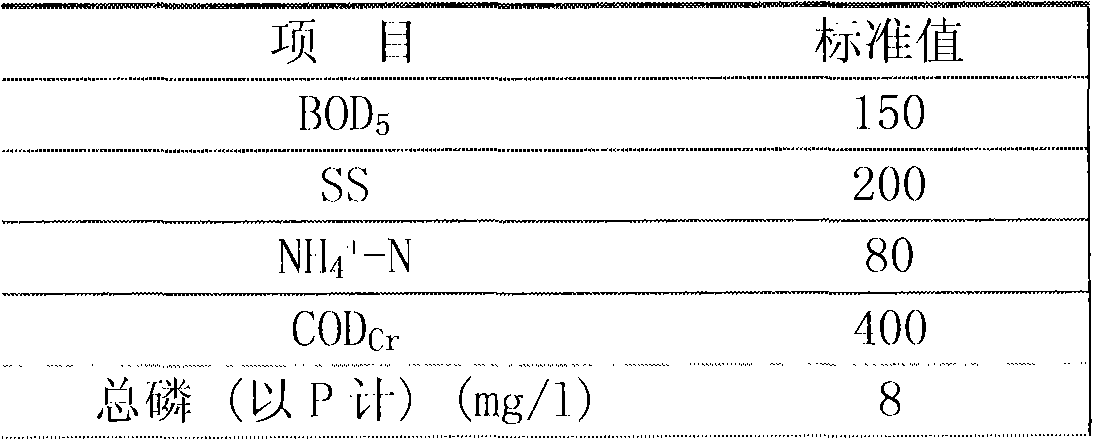

Embodiment 1

[0023] Example 1: The raw water is wastewater from a large-scale pig farm, and the daily treatment capacity is 150m 3 / d, raw water quality: COD5000~10000mg / L, NH 4 + -N 400~1500mg / L TP30~100mg / L. The raw water enters the hydrolytic acidification tank, and then enters the anaerobic reactor, using the metabolic function of heterotrophic bacteria to decompose the refractory organic matter into easily biodegradable small molecule organic matter, and at the same time mineralize the organic nitrogen, degrade and remove most of the easily biodegradable organic matter . But the anaerobic part does not remove NH 4 + -N, the anaerobic environment increases TP instead, and the effluent COD of the anaerobic reactor is 500-1000mg / L, NH 4 + -N 400~1500mg / L TP 50~150mg / L; After the effluent from the anaerobic reactor passes through the SBBR reactor, determine the operating conditions of the SBBR: water inflow for 1h, anaerobic for 3h, aerobic for 7h, precipitation for 0.5h, and draina...

Embodiment 2

[0024] Example 2: The raw water is wastewater from a certain large-scale pig farm, and the daily treatment capacity is 150m 3 / d, raw water quality: COD4000~8000mg / L, NH 4 + -N 320~1200mg / L TP24~80mg / L. The raw water enters the hydrolytic acidification tank, and then enters the anaerobic reactor, using the metabolic function of heterotrophic bacteria to decompose the refractory organic matter into easily biodegradable small molecule organic matter, and at the same time mineralize the organic nitrogen, degrade and remove most of the easily biodegradable organic matter . But the anaerobic part does not remove NH 4 + -N, the anaerobic environment increases TP instead, and the effluent COD of the anaerobic reactor is 400-800mg / L, NH 4 +-N320~1200mg / L TP 40~120mg / L; After the effluent from the anaerobic reactor passes through the SBBR reactor, determine the operating conditions of the SBBR: water inflow for 1h, anaerobic for 3h, aerobic for 7h, precipitation for 0.5h, and dra...

Embodiment 3

[0025] Example 3: The raw water is wastewater from a certain large-scale pig farm, and the daily treatment capacity is 150m 3 / d, raw water quality: COD6000~12000mg / L, NH 4 + -N 480~1800mg / L TP36~120mg / L. The raw water enters the hydrolytic acidification tank, and then enters the anaerobic reactor, using the metabolic function of heterotrophic bacteria to decompose the refractory organic matter into easily biodegradable small molecule organic matter, and at the same time mineralize the organic nitrogen, degrade and remove most of the easily biodegradable organic matter . But the anaerobic part does not remove NH 4 + -N, the anaerobic environment increases TP instead, and the effluent COD of the anaerobic reactor is 600-1200mg / L, NH 4 + -N 480~1800mg / L TP 60~180mg / L; After the effluent from the anaerobic reactor passes through the SBBR reactor, determine the operating conditions of the SBBR: water inflow for 1h, anaerobic for 3h, aerobic for 7h, precipitation for 0.5h, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com