Selective hydrogenation method of highly unsaturated hydrocarbons in cracking gas

A technology for selective hydrogenation and cracking gas, used in the processing of gas mixtures, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of high conversion rate, reduce the number of reaction units, increase life, improve selectivity and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Preparation of nickel-molybdenum-zinc / alumina catalyst

[0065] The alumina-supported BC-H-2008 catalyst containing 15% Ni, 1% Mo and 1% Zn was prepared by equal volume impregnation method. Dissolving an appropriate amount of nickel nitrate, ammonium molybdate and zinc nitrate in water to prepare a solution, then impregnating the alumina support in the solution, drying, calcining and reducing to obtain the required non-precious metal catalyst.

[0066] (2) Preparation of palladium / alumina catalyst

[0067] The alumina-supported BC-L-83A catalyst containing 0.1% Pd was prepared by equal volume impregnation method. The alumina carrier is immersed in palladium solution, dried, calcined and reduced to obtain the required noble metal catalyst.

[0068] (3) Selective hydrogenation of cracked gas

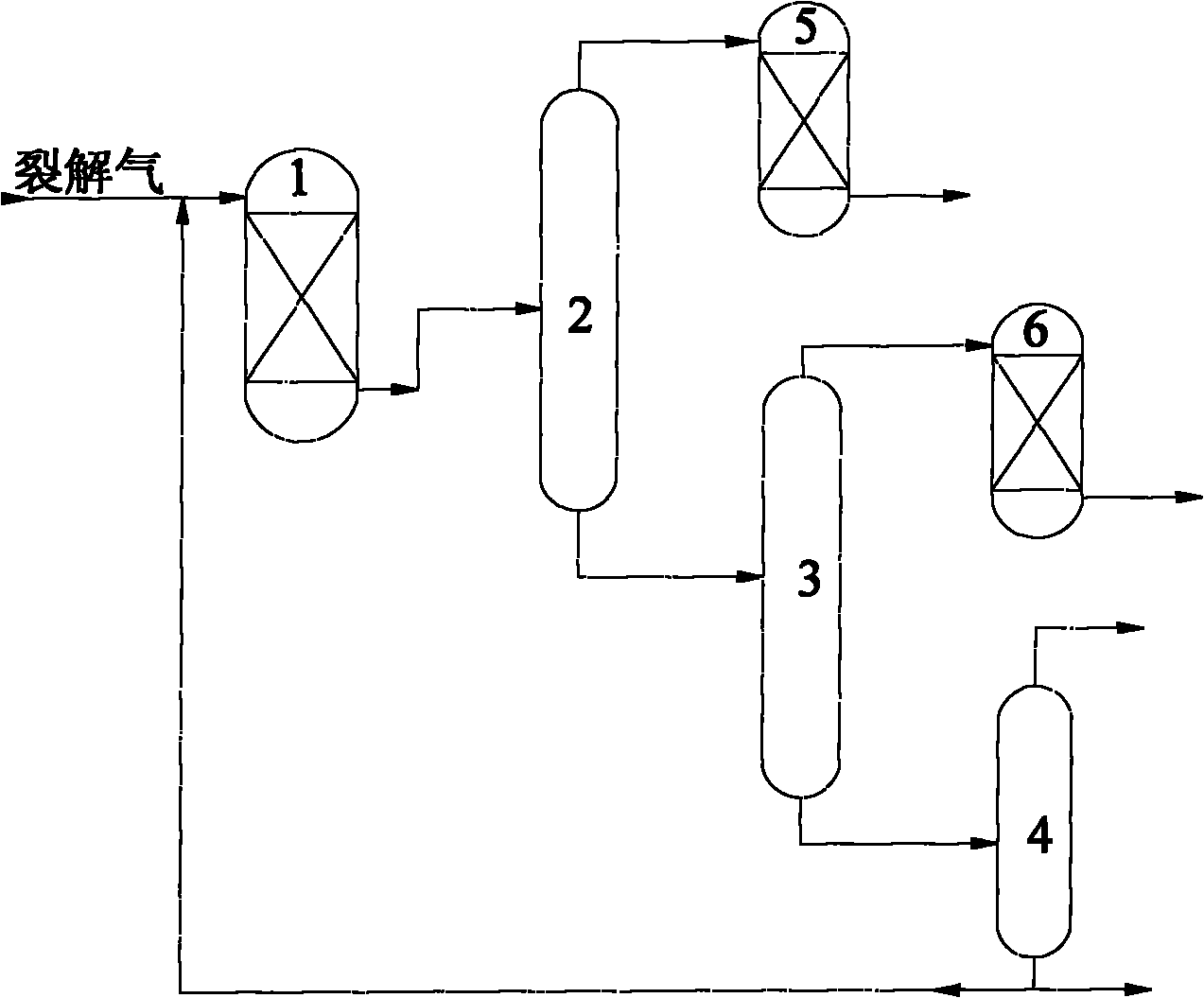

[0069] see figure 1 , the gas phase raw material 1 containing olefins obtained from the steam cracking unit, the specific composition can refer to the following table 1, mix...

Embodiment 2

[0075] Utilize the olefin-containing gas phase stream obtained from the steam cracking unit as raw material, the specific composition of the stream is the same as in Example 1, mixed with the liquid phase stream coming from the bottom of the debutanizer, then heat exchanged in a heat exchanger, and enter Mixed Phase Hydrogenation Reactor 1. Mixed-phase hydrogenation reactor 1 is filled with palladium catalyst, Ni catalyst (two kinds of catalysts are produced by China Petroleum and Chemical Corporation Beijing Research Institute of Chemical Industry) and upper layer of Ni catalyst and lower layer of palladium catalyst (catalyst combination). The mixed-phase selective hydrogenation reaction test of highly unsaturated hydrocarbons in cracked gas was carried out under different conditions. The reaction conditions were: reaction pressure 2.0MPa, reaction inlet temperature 65°C, gas hourly volume space velocity 3000h -1 , Liquid hourly volume space velocity 7.5h -1 , and the evalua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com