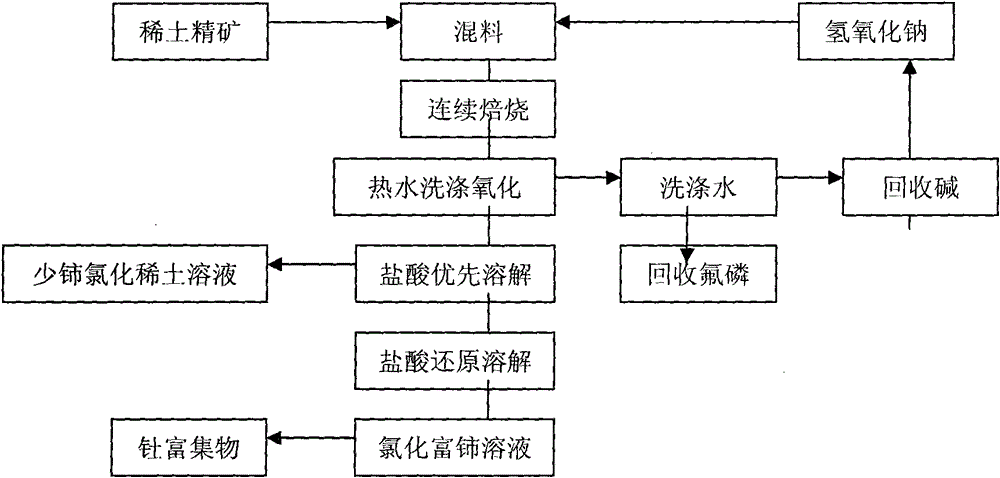

Liquid alkali roasting decomposition extraction process of mixed rare earth concentrates

A mixed rare earth and extraction process technology, which is applied in the field of mixed rare earth concentrate liquid alkali roasting, decomposition and extraction process, can solve the problems of non-continuous production, reduce the extraction and separation processing capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 500g of sodium hydroxide to make a 70wt% solution, add 500g of mixed rare earth ore (REO 57wt%), and mix it in and out of the rotary kiln continuously. The residence time in the kiln is 1.5 to 2.0 hours. The temperature is 190°C and the outlet temperature is 230°C. The roasted ore after roasting automatically enters the collecting hopper at the outlet of the rotary kiln. Roast ore hot water to adjust slurry, add oxidant hydrogen peroxide and react at 50-60°C for 2 hours, then wash with water until neutral, dissolve preferentially with 6M hydrochloric acid, control solution pH=4~5 to obtain cerium-less rare earth chloride solution; use 6M Hydrochloric acid and hydrogen peroxide are reduced and dissolved to obtain cerium-rich and thorium-rich chloride concentrates. In rare earth chloride solution with less cerium, CeO 2 / REO=2.5%, CeO in cerium-rich chloride solution 2 / REO=98.8%, the oxidation rate of cerium is 98.9%, and the total yield of rare earth is 95.6%. ...

Embodiment 2

[0031] Take 500g of sodium hydroxide to make a 70wt% solution, add 500g of mixed rare earth ore (REO 57wt%), and mix it in and out of the rotary kiln continuously. The residence time in the kiln is 1.5 to 2.0 hours. The temperature is 190°C and the outlet temperature is 230°C. The roasted ore after roasting automatically enters the collecting hopper at the outlet of the rotary kiln. Roast ore with hot water to adjust slurry, pass air into it and react at 80-90°C for 4 hours, wash with water until neutral, dissolve preferentially with 9M hydrochloric acid, control the pH of the solution to 4-5 to obtain a rare earth chloride solution with less cerium; use 9M hydrochloric acid Reductive dissolution with hydrogen peroxide to obtain cerium-rich and thorium-rich chloride concentrates. In rare earth chloride solution with less cerium, CeO 2 / REO=4.5%, CeO in cerium-rich chloride solution 2 / REO=96.4%, the oxidation rate of cerium is 95.3%, and the total yield of rare earth is 95....

Embodiment 3

[0033] Take 500g of sodium hydroxide to make a 70wt% solution, add 500g of mixed rare earth ore (REO 57wt%), and mix it in and out of the rotary kiln continuously. The residence time in the kiln is 1.5 to 2.0 hours. The temperature is 190°C and the outlet temperature is 230°C. The roasted ore after roasting automatically enters the collecting hopper at the outlet of the rotary kiln. Roast mineral hot water to adjust slurry, feed chlorine gas and react at 80-90°C for 3 hours, wash with water until neutral, dissolve preferentially with 6M hydrochloric acid, control solution pH = 4-5 to obtain rare earth chloride solution with less cerium; use 6M hydrochloric acid Reductive dissolution with hydrogen peroxide to obtain cerium-rich and thorium-rich chloride concentrates. In rare earth chloride solution with less cerium, CeO 2 / REO=2.2%, CeO in cerium-rich chloride solution 2 / REO=98.4%, the oxidation rate of cerium is 98.2%, and the total yield of rare earth is 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com