Preparation method of modified cathode material of lithium ion battery and battery applying same

A technology of lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., to improve safety performance and cycle performance, and reduce side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The vinylidene fluoride and hexafluoropropylene copolymer were dissolved in acetone, and the temperature was kept at 40 ° C, then the industrially produced conventional lithium cobalt oxide matrix material was added, and stirred for 1 h, and then solid-liquid separation was carried out. Bake in an oven at ℃ for 12 h to obtain a lithium cobalt oxide modified cathode material.

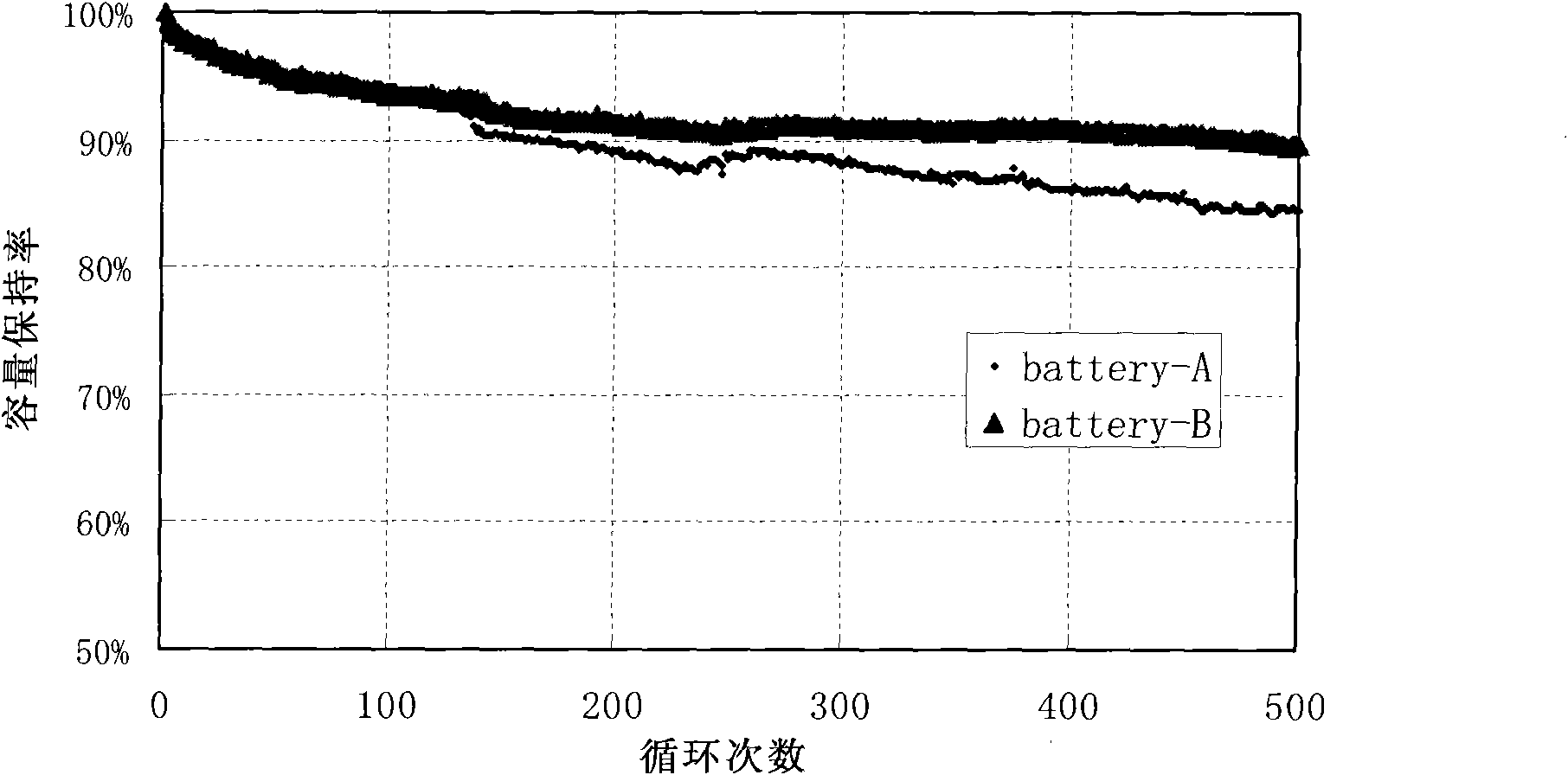

[0018] The performance of the material was tested with a 053450 type polymer battery. The conventional lithium cobalt oxide and lithium cobalt oxide modified materials were used as the cathode active material, the anode was made of acicular artificial graphite, and the electrolyte was made of PE / PP / PE three-layer microporous membrane. , the electrolyte adopts 1MLiPF 6 / EC:EMC:DEC=1:1:1 system in which dibutyl phthalate was added as plasticizer and azobisisobutyronitrile as initiator. After the vacuum packaging of the battery using the modified cathode material, under the conditions of a temperatu...

Embodiment 2

[0026] The homopolymer of ethylene oxide and propylene oxide with a molecular weight of 30,000 was dissolved in ethyl formate, and the temperature was kept at 50 ° C, and then the conventional industrially produced LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 The base material was added and stirred for 2 hours, and then solid-liquid separation was carried out. The solid phase was baked in an oven at 110 °C for 12 hours to obtain LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 Modified cathode material.

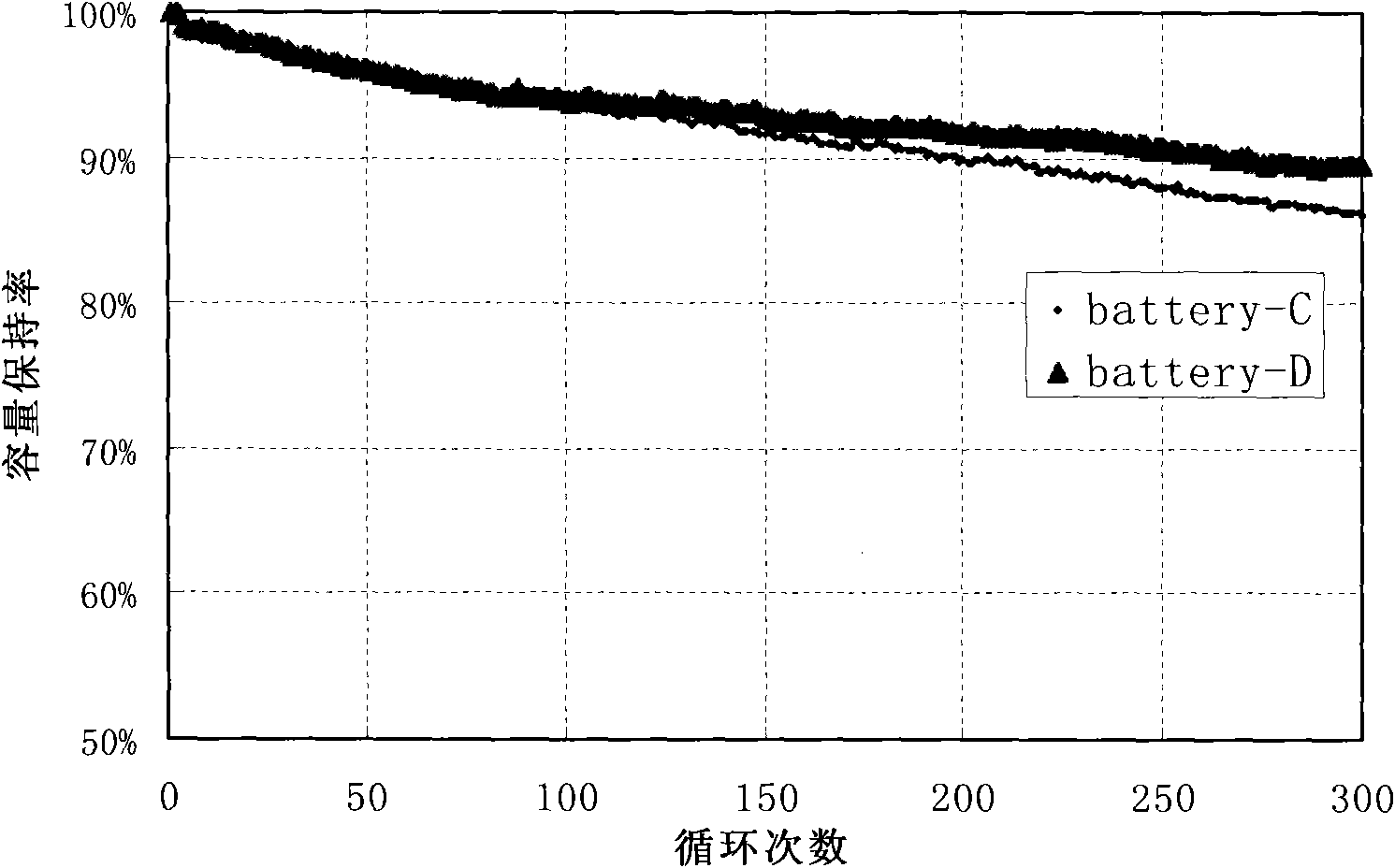

[0027] The performance of the material was tested with a polymer battery of type 053450, and the conventional LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 and LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 The modified material is the cathode active material, the anode adopts acicular artificial graphite, the electrolyte adopts PE / PP / PE three-layer microporous membrane, and the electrolyte adopts 1MLiPF 6 / EC:EMC:DEC=1:1:1 system and adding dioctyl phthalate as plasticizer, dicumyl peroxide as initiator and cyclohexylbenzene functional add...

Embodiment 3

[0035] The copolymer of vinylidene fluoride and hexafluoropropylene, and the copolymer of ethylene oxide and propylene oxide with a molecular weight of 30,000 were dissolved in tetrafluorohydrofuran, and the temperature was kept at 60 ° C, and then the industrially produced conventional LiNi 0.75 Co 0.20 Al 0.05 O 2 The base material was added and stirred for 1 hour, and then solid-liquid separation was carried out. The solid phase was baked in an oven at 100 °C for 12 hours to obtain LiNi 0.75 Co 0.20 Al 0.05 O 2 Modified cathode material.

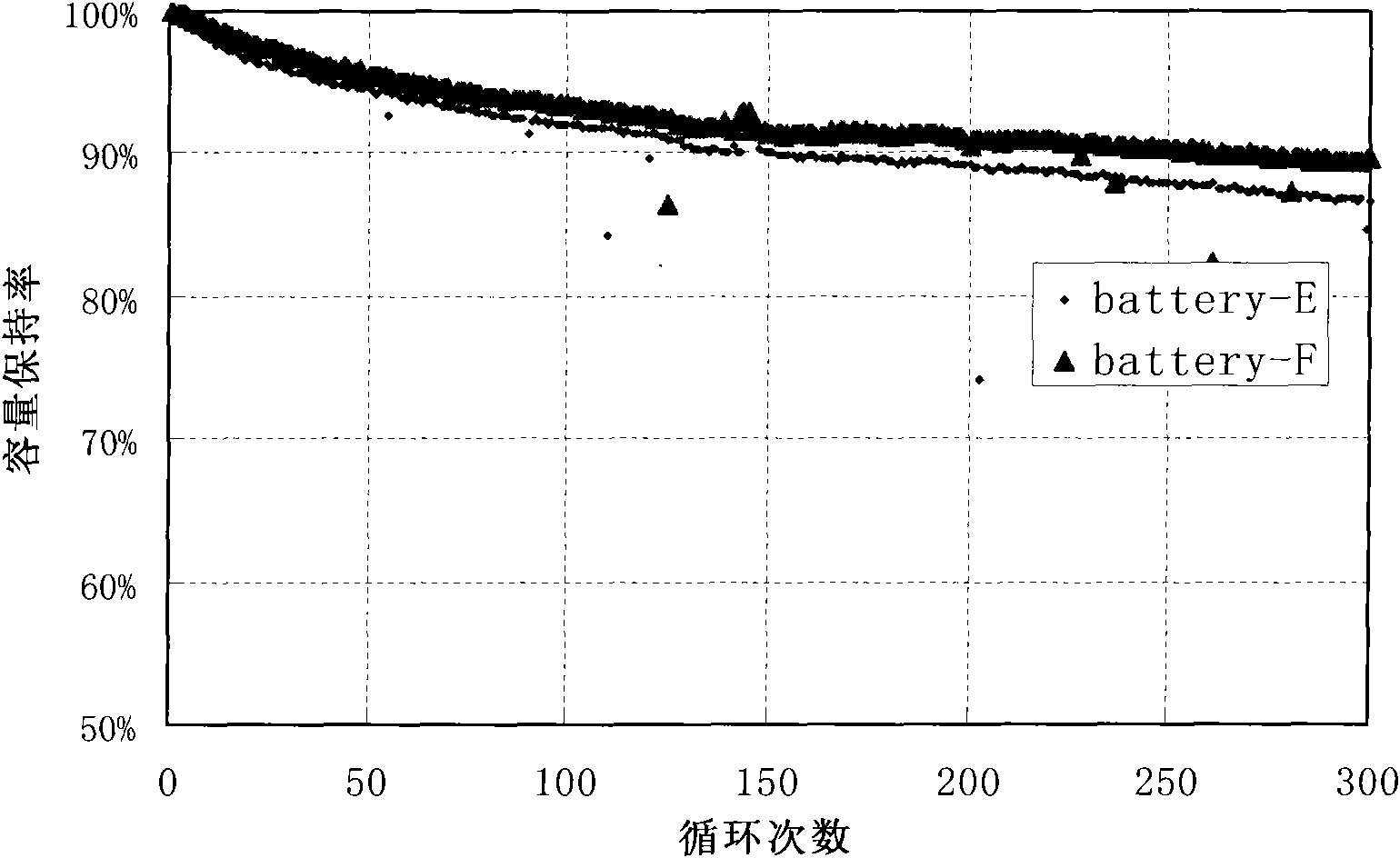

[0036] The performance of the material was tested with a polymer battery of type 053450, and the conventional LiNi 0.75 Co 0.20 Al 0.05 O 2 and LiNi 0.75 Co 0.20 Al 0.05 O 2 The modified material is the cathode active material, the anode adopts acicular artificial graphite, the electrolyte adopts PE / PP / PE three-layer microporous membrane, and the electrolyte adopts 1MLiPF 6 / EC:EMC:DEC=1:1:1 system in which n-octyl-n-decyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com