Super early strength polymer rapid-patching motar material

A technology for repairing mortar and polymer is applied in the field of rapid repair of surface defects of bridge beams and road concrete structures of high-speed railway passenger dedicated lines, which can solve the problems of hourly strength, low bonding strength and flexural strength, etc., to improve work performance and Appearance, improved working performance, high bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

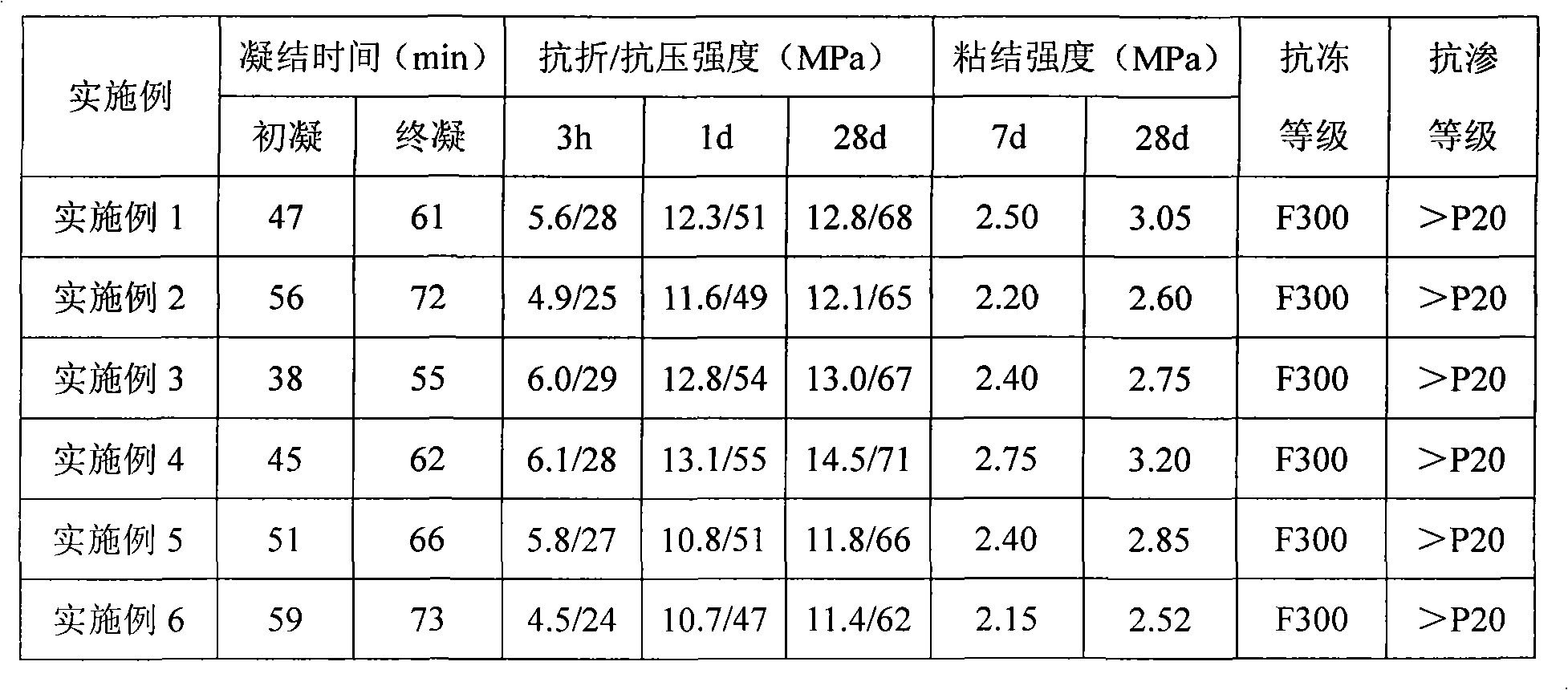

Embodiment 1

[0031] Rapid hardening sulfoaluminate cement: 46.3% (mass percentage); Quartz sand: 47%; Vinyl acetate / ethylene copolymer rubber powder: 5%; Hydroxyethyl methyl cellulose ether: 0.2%; Borax: 0.4%; Sulfuric acid 1:1 mixing of aluminum and calcium fluoride: 0.2%; naphthalene sulfonate superplasticizer (powder); 0.55%; silicone defoamer: 0.06%; 6mm polypropylene fiber: 0.02%.

[0032] When using on site, mix the dry powder of repair mortar and water at a ratio of 1:0.13 to form a slurry evenly. Referring to "Polymer Cement Waterproof Mortar" JC / T 984-2005, the measured positive tensile bond strength of the obtained repair mortar is 2.5MPa at 7d, 3.0MPa at 28d, 28MPa at 3h, and 28MPa at 1d. The strength is 51MPa, and the 1d flexural strength is 12.3MPa.

Embodiment 2

[0034] Rapid hardening sulfoaluminate cement: 40.0% (mass percentage); Quartz sand: 50.3%; Carboxylic acid block copolymer powder: 8%; Hydroxyethyl methyl cellulose ether: 0.3%; Borax: 0.4%; Aluminum sulfate and calcium fluoride 1:1 mixed: 0.3%; polycarboxylate superplasticizer (powder); 0.24%; polyether defoamer: 0.04%; 3mm polypropylene fiber: 0.02%.

[0035] The measured positive tensile bond strength of the obtained repair mortar was 2.2MPa at 7d, 2.6MPa at 28d, 25MPa at 3h, 49MPa at 1d, and 11.6MPa at flexural strength at 1d.

Embodiment 3

[0037] Rapid hardening sulfoaluminate cement: 50.0% (mass percentage); Quartz sand: 44.4%; Acrylic polymer rubber powder: 3%; Hydroxypropyl methyl cellulose ether: 0.3%; Citric acid: 0.9%; 1:1 mixing of aluminum sulfate and calcium formate: 0.8%; polycarboxylate superplasticizer (powder); 0.40%; polyether defoamer; 0.07%; 9mm polypropylene fiber: 0.08%.

[0038] The measured positive tensile bond strength of the obtained repair mortar was 2.4MPa at 7 days, 2.75MPa at 28 days, 29MPa at 3 hours, 54MPa at 1 day, and 12.8MPa at 1 day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com