Composite material of poly(p-dioxanone)/inorganic nano-fiber and preparation method thereof

A polydioxanone and inorganic nanofiber technology, applied in the field of polydioxanone/inorganic nanofiber composite materials and their preparation, can solve the problem of uneven dispersion, easy formation, and the improvement of PPDO performance by up to Less than ideal effect and other problems, to achieve the effect of improving melt strength, improving processability, and good interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

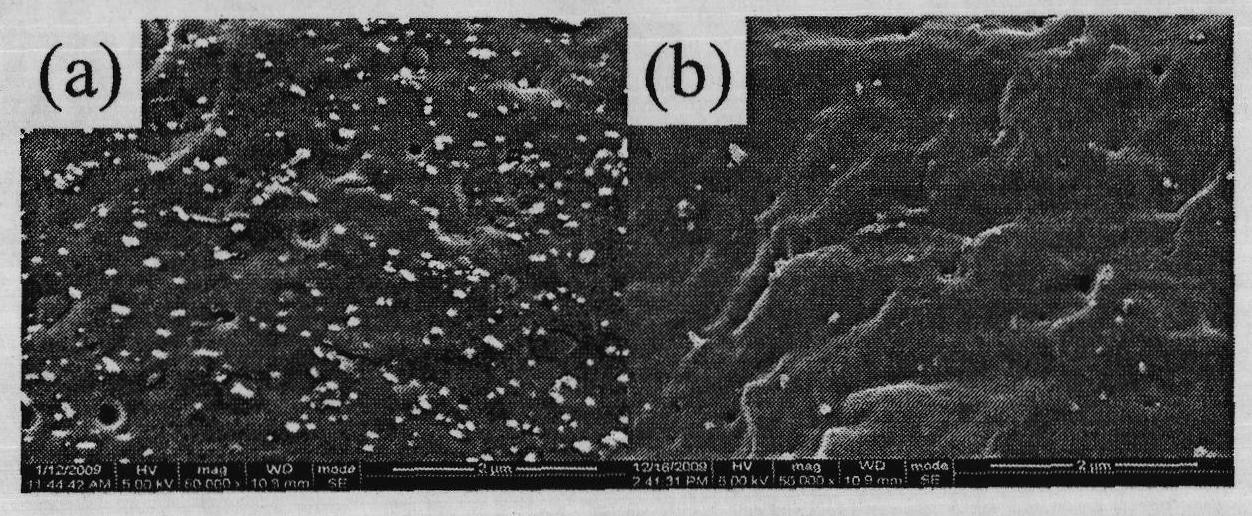

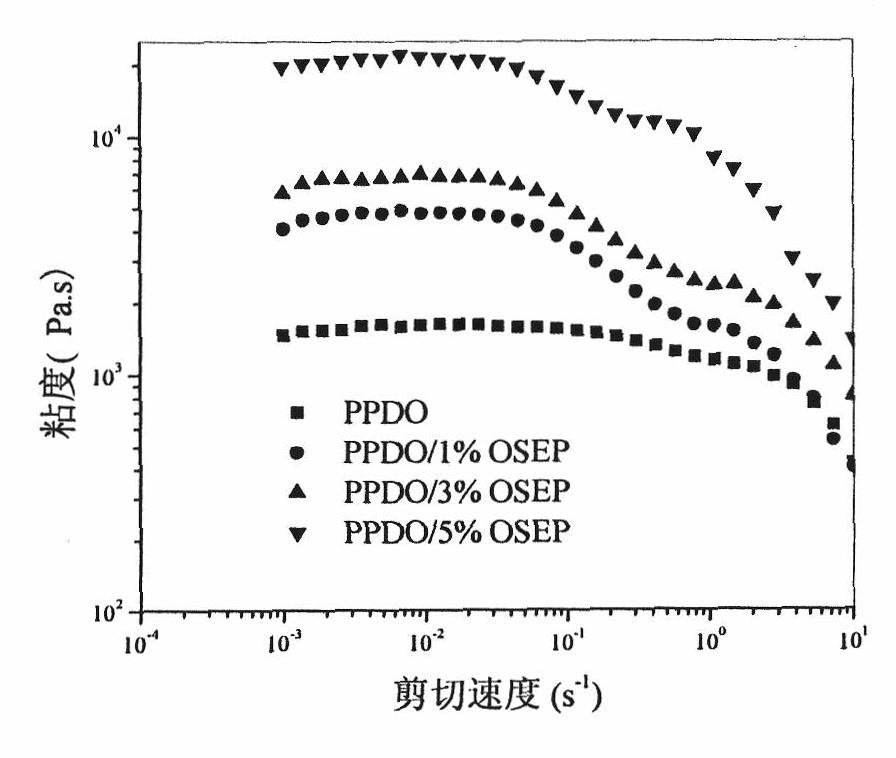

[0025] First add 10g of sepiolite to 400ml of deionized water, stir at high speed for 1 hour to obtain a stable suspension, then dissolve 3g of cetyltrimethylammonium bromide in 100ml of deionized water, and then slowly drop the latter Add it into the suspension, continue to stir at high speed and raise the temperature to 80°C, react for 12 hours, filter with suction, and wash with deionized water repeatedly until there is no bromide ion in the filtrate with 0.1mol / L silver nitrate solution; finally freeze-dry To the constant weight of the sepiolite, grind it through a 200-mesh sieve.

[0026] Add 100 g of p-dioxanone monomer and 3 g of treated organic sepiolite into a reaction bottle protected by a nitrogen atmosphere, stir and mix and swell at 50°C for 1 h, and then ultrasonically disperse for 0.5 h to make the sea foam The stone nanofibers were fully unbundled and dispersed, then the temperature was raised to 60° C., 0.001 triethylaluminum was added in terms of monomer mole...

Embodiment 2

[0028] First dry the chrysotile in a vacuum oven at 100°C for 48 hours, then add 10g of dried chrysoprite and 5g of silane coupling agent KH550 into 500ml of toluene, stir at high speed and raise the temperature to 110°C and reflux for 12 hours. Then filter and extract with toluene for 48 hours, and finally vacuum-dry at 70°C until the chrysoprite has constant weight, and grind it through a 200-mesh sieve.

[0029] Add 100 g of p-dioxanone monomer and 0.5 g of treated organic chemical fiber serpentine into a reaction bottle protected by a nitrogen atmosphere, stir, mix and swell at 50°C for 2 h, and then ultrasonically disperse for 0.5 h to make the fiber The serpentine nanofibers were fully unbundled and dispersed, then the temperature was raised to 80° C., 0.0005 stannous octoate was added in terms of monomer moles, and the polydioxanone / inorganic nanofiber composite material was obtained after reacting for 48 hours.

Embodiment 3

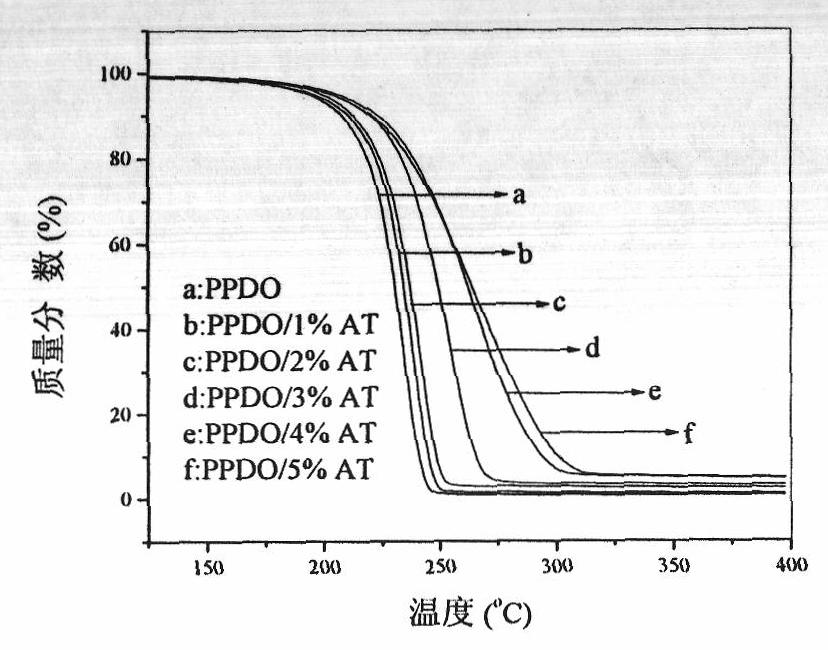

[0031] First dry the attapulgite in a vacuum oven at 100°C for 48 hours, then add 10g of the dried attapulgite and 5g of titanate coupling agent NDZ102 into 500ml of isopropanol, stir at high speed and heat to 80°C for reflux for 12h, then Filter and extract with isopropanol for 48 hours, and finally vacuum-dry at 70°C until the attapulgite has constant weight, and grind through a 200-mesh sieve.

[0032] Add 100 g of p-dioxanone monomer and 5 g of the treated organic attapulgite into a reaction bottle protected by a nitrogen atmosphere, stir, mix and swell at 50°C for 2 hours, and then ultrasonically disperse for 1 hour, so that the attapulgite nanofibers Fully unbundle and disperse, then raise the temperature to 80°C, add 0.00125 aluminum isopropoxide in terms of monomer moles, and react for 12 hours to obtain a polydioxanone / inorganic nanofiber composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com