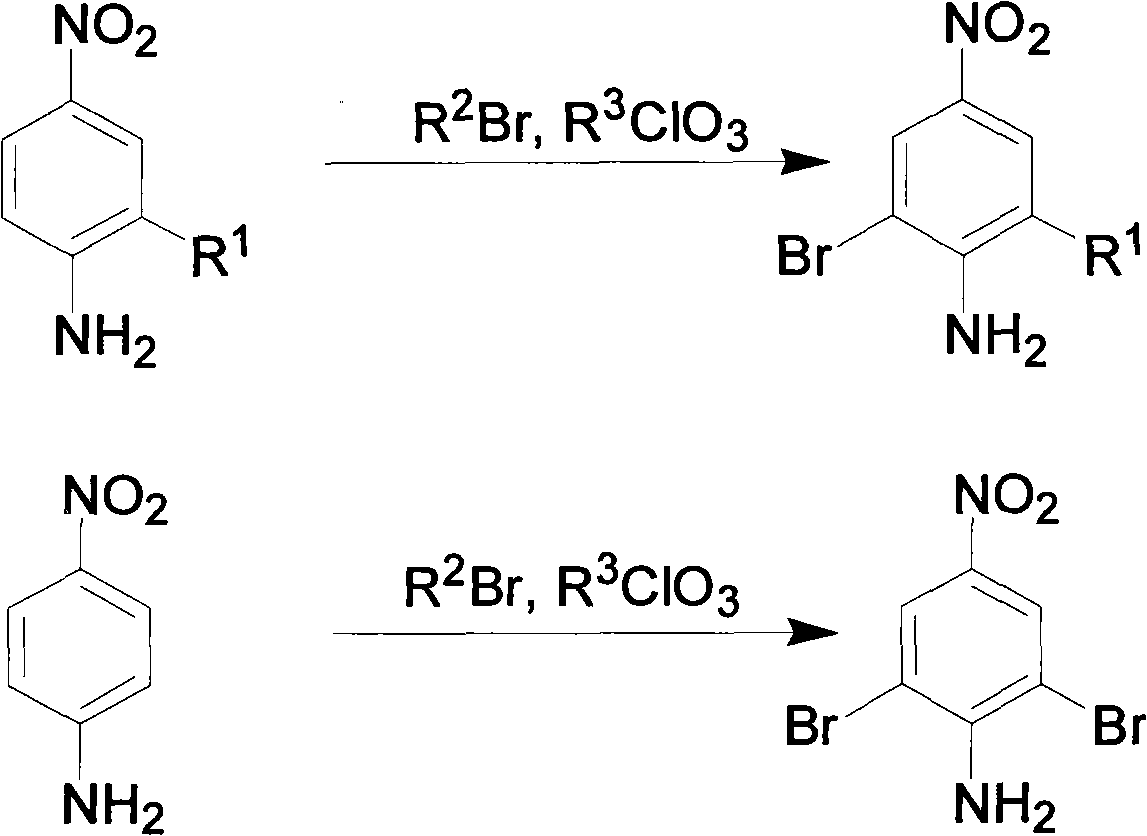

Preparation method of bromo-nitroaniline dye stuff intermediate

A technology for dye intermediates and nitroaniline is applied in the field of synthesis of bromonitroaniline dye intermediates, can solve the problems of high cost, high cost of bromine, large amount of sodium hypochlorite, etc., and achieves good quality and complete bromination reaction. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 5000L still, add 4000L of solution containing potassium bromide (concentration of 7.5% by mass in terms of bromide ions), distill 2000L of water through distillation, add 20 kg of active carbon, decolorize and filter, then add flocculant and other precipitation and filter to obtain the concentration Be 15% (mass percent concentration in terms of bromide ions) potassium bromide solution;

[0022] In the enamel reaction kettle of 5000L, add the potassium bromide solution 2735kg that the concentration that recovers is 15% (mass percentage concentration in terms of bromide ion), slowly add 480kg of 98% sulfuric acid, stir for 30 minutes, drop into 2,4-di Nitroaniline 880kg, and be warming up to 35 ℃, slowly add the concentration that has been prepared dropwise and be 540kg of 30% sodium chlorate solution, add, keep warm for half an hour, heat up to 75 ℃, keep warm for 2 hours, cool to room temperature, Filtrate, wash the filter cake with water until the pH value is 5-8...

Embodiment 2

[0024] The hydrobromic acid obtained by absorbing the waste gas containing hydrogen bromide through multi-stage water absorption or falling film absorption is used as the bromination raw material for standby when the bromide ion content in the hydrobromic acid solution reaches 20%.

[0025] In a 5000L enamel reaction kettle, add 2050kg of hydrobromic acid solution with a prepared concentration of 20% (mass percentage concentration in terms of bromide ions), slowly add 490kg of 98% sulfuric acid, stir for 30 minutes, and drop 2,4 -Dinitroaniline 880kg, and heat up to 40°C, slowly add 552kg of 30% sodium chlorate solution dropwise, after adding, keep warm for half an hour, heat up to 70°C, keep warm for 2 hours, and cool to room temperature , filtered, the filter cake was washed with water until the pH value was 5-8, and dried to obtain 1240 kg of bright yellow 2,4-dinitro-6-bromoaniline, with a yield of 98% and a product purity of ≥98%.

Embodiment 3

[0027] Add 4000L of sodium bromide solution with a concentration of 9% (mass percentage concentration in terms of bromide ions) in a 5000L distillation kettle, distill 1000L of water, add 15 kg of activated carbon, decolorize and filter, then add flocculants and other precipitation and filter Obtaining the potassium bromide solution that obtaining concentration is 15% (mass percent concentration in bromide ion);

[0028] In a 5000L enamel reaction kettle, add 1425kg of recovered 12% sodium bromide solution (mass percentage concentration in terms of bromide ions), slowly add 333kg of 98% sulfuric acid, stir for 30 minutes, and drop in 2-cyano-4 - Nitroaniline 326kg, and heat up to 43°C, slowly add 300kg of sodium chlorate solution with a concentration of 25% dropwise, after adding, keep warm for half an hour, heat up to 70°C, keep warm for 2 hours, and cool to room temperature , filtered, the filter cake was washed with water until the pH value was 5-8, and dried to obtain 480 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com