Method for preparing paraformaldehyde

A paraformaldehyde and formaldehyde solution technology, applied in the field of preparation of paraformaldehyde, can solve the problems that the polymer cannot be fully decomposed into polyoxymethylene monomers, the molecular weight can not be uniformly distributed, and the polymerization activity can not be reduced. , to reduce the formation of insoluble matter, prolong the storage time, and avoid the growth of molecular chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

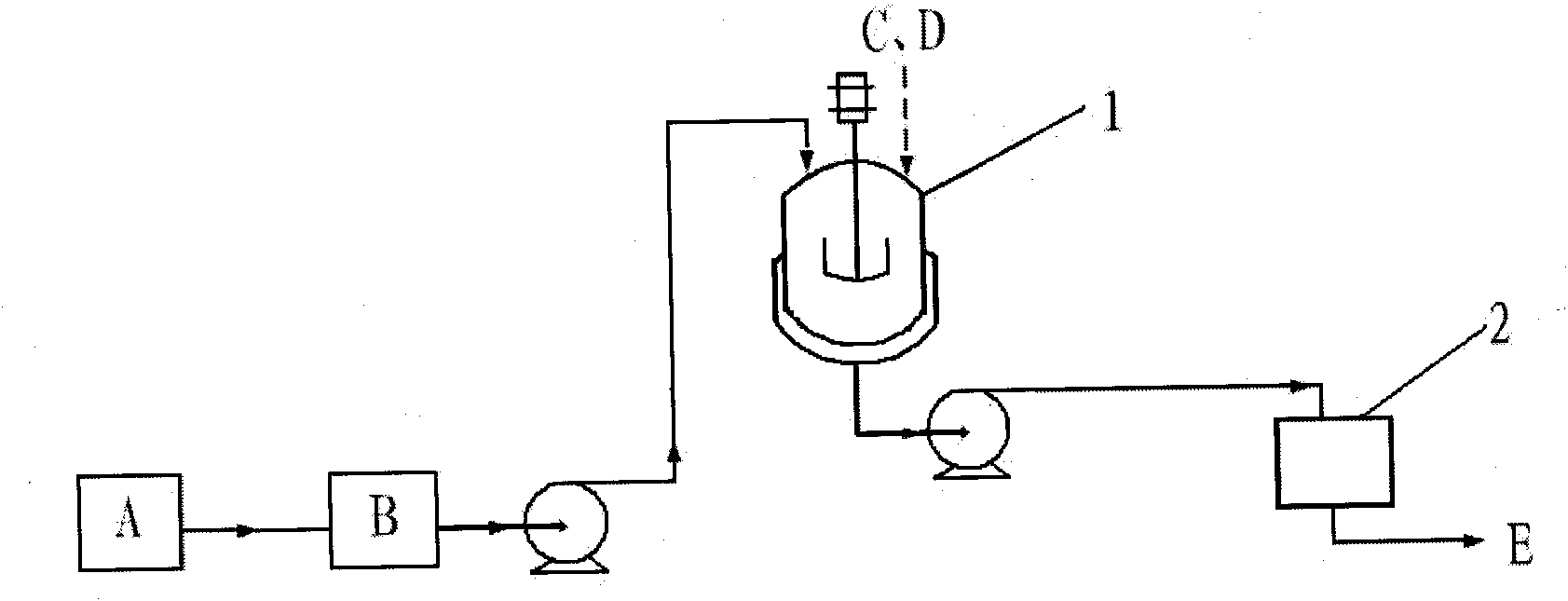

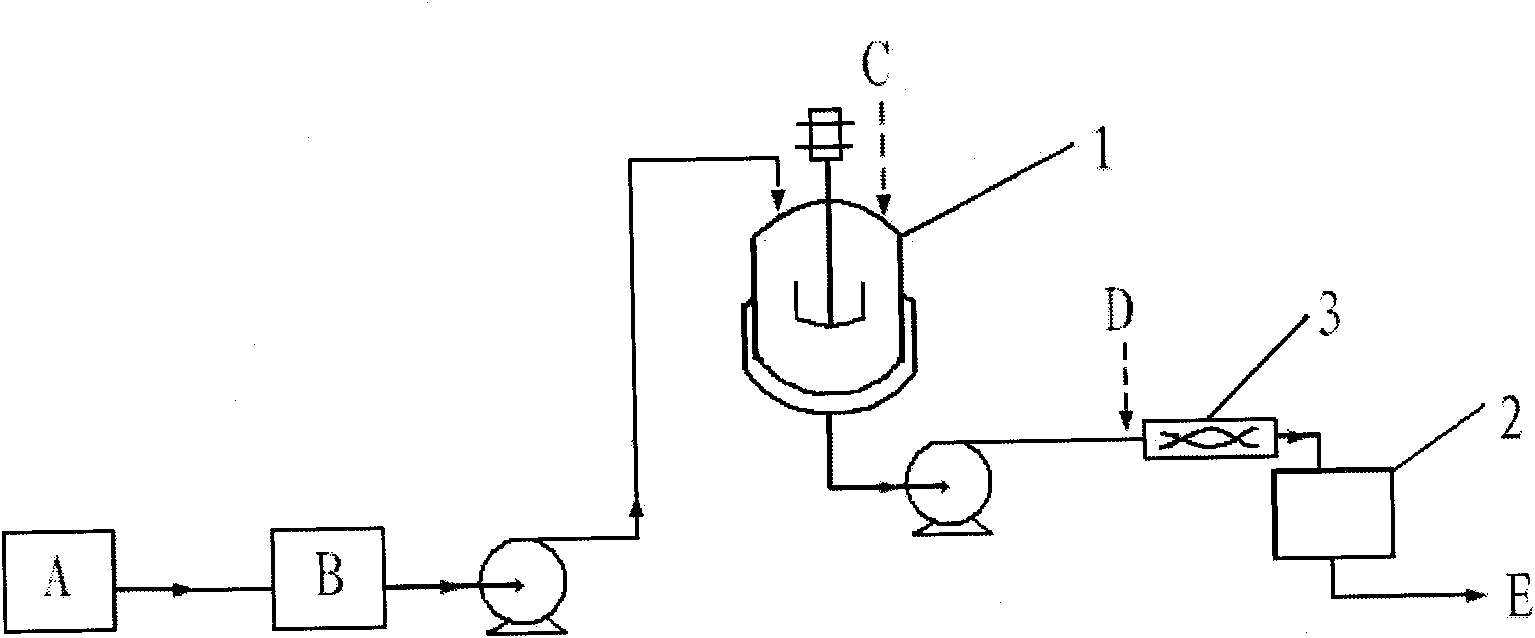

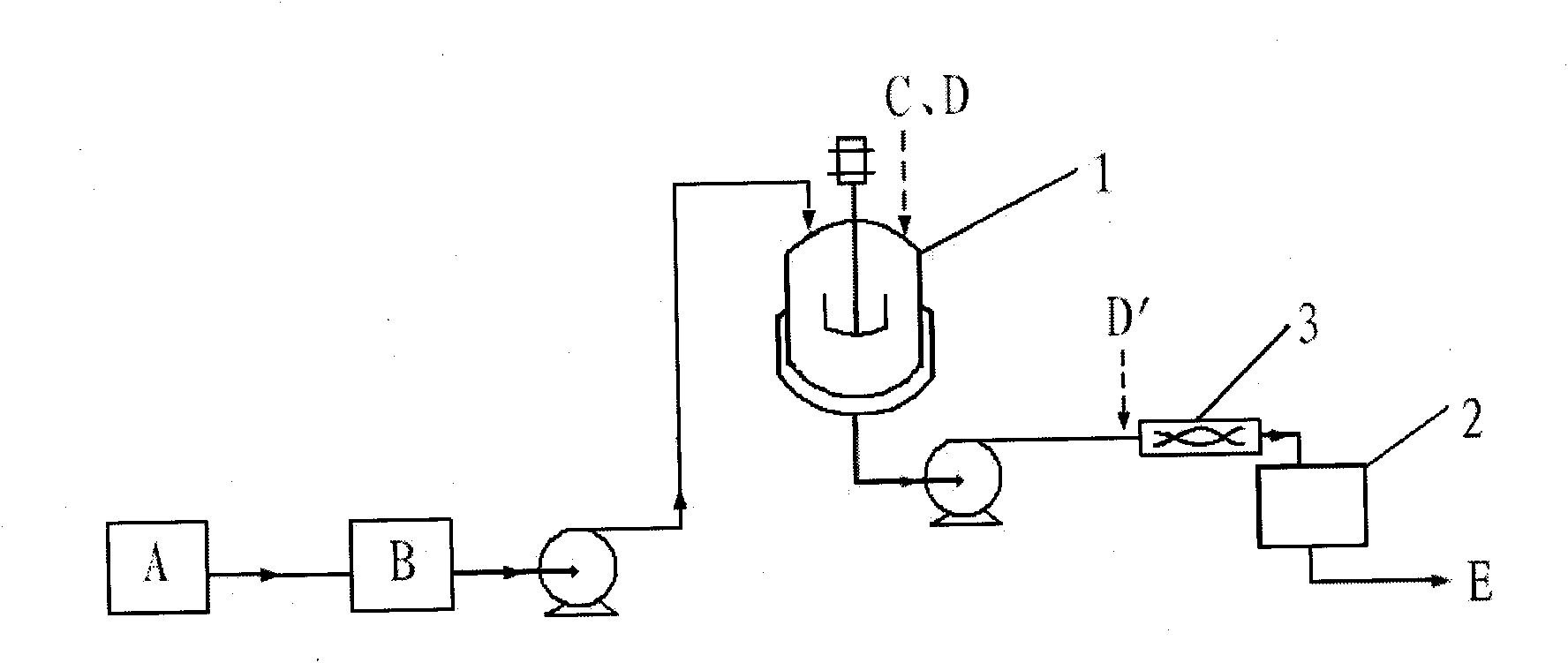

Method used

Image

Examples

Embodiment 1

[0057] The formaldehyde solution is concentrated to 75wt% concentrated formaldehyde solution, then pumped into a buffer tank equipped with stirring and heating devices, the temperature in the buffer tank is maintained at 98 ° C, and 80 g of methanol is added to 1000 g of the above-mentioned concentrated formaldehyde solution , after stirring and mixing for 0.5 hours, add 0.5 g of a catalyst compounded by triethanolamine and diethanolamine according to the mass ratio of 1:2, and after stirring and mixing for 0.5 hours, a reaction product is obtained, and the acidic substance content in the reaction product is ≤30ppm , and then pump the reaction product to a multi-stage fluidized bed cascade spray drying system for drying to obtain paraformaldehyde solid particles with an aldehyde content of 95.4%. The degree of polymerization of the final product is 10. After 100 days at room temperature, the The solubility of the product in water is 100%, so the product can be stored at room te...

Embodiment 2

[0059] The formaldehyde solution is concentrated into 80wt% concentrated formaldehyde solution, then pumped into a buffer tank equipped with stirring and heating devices, the temperature in the buffer tank is maintained at 95°C, and 50g of methanol is added to 1000g of the above-mentioned concentrated formaldehyde solution , after stirring and mixing for 0.2 hours, add 0.3 g of a catalyst compounded by triethanolamine, ethanolamine and diethylamine according to the mass ratio of 3:1:1, and stir and mix for 1 hour to obtain a reaction product, in which The acidic substance content is ≤ 50ppm, and then the reaction product is pumped to a single-stage fluidized bed cascade spray drying system for drying to obtain paraformaldehyde solid particles with an aldehyde content of 96.3%, and the degree of polymerization of the final product is 12. After 120 days of storage under high temperature, the solubility of the product in water is 100%, that is, the product at room temperature can ...

Embodiment 3

[0061] The formaldehyde solution is concentrated into 85wt% concentrated formaldehyde solution, then pumped into a buffer tank equipped with stirring and heating devices, the temperature in the buffer tank is maintained at 102°C, and 50 g of the above-mentioned concentrated formaldehyde solution is added according to The mixture of methanol and propanol compounded at a mass ratio of 2: 1 was stirred and mixed for 4 hours to obtain a reaction product. During the process of pumping the reaction product to the drying system, 0.7 g of diethanolamine and tris Ethylamine is a catalyst compounded according to a mass ratio of 1:1, and mixed by a mixer, the acidic substance content in the resulting mixture is ≤ 60ppm, and the mixture is pumped to a multi-stage fluidized bed cascade spray drying system for drying, Obtained paraformaldehyde solid particles with an aldehyde content of 95.4%, the degree of polymerization of the final product is 9, and after storage at room temperature for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com