Method for preparing high-yield SiC nanowire

A nanowire, high-yield technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of laser ablation method, such as complex preparation of instruments, difficulty in industrialized production, and influence on product purity, so as to achieve cheap raw materials and low cost of instruments. The effect of low requirements and no catalyst use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for preparing high-yield SiC nanowires in this embodiment is achieved through the following steps:

[0019] 1. 70% by mass percentage of industrial silicon powder (6000 mesh, Si content > 99.3%) and 30% by mass percentage of industrial flake-like expandable graphite are mechanically mixed;

[0020] 2. Put the raw material mixture into a graphite crucible, place it in a high-temperature atmosphere furnace, and evacuate to 10 4 Pa to exclude oxygen;

[0021] 3. Argon is filled as a protective gas, so that the pressure in the furnace is 2×10 4 Pa;

[0022] 4. Raise the temperature to 1500°C at a rate of 8°C / min, hold for 5 hours, and keep the pressure in the furnace lower than 0.15MPa during the entire preparation process;

[0023] 5. Naturally cool to room temperature, and start the furnace to obtain SiC nanowires.

[0024] The SiC nanowire yield was 65%.

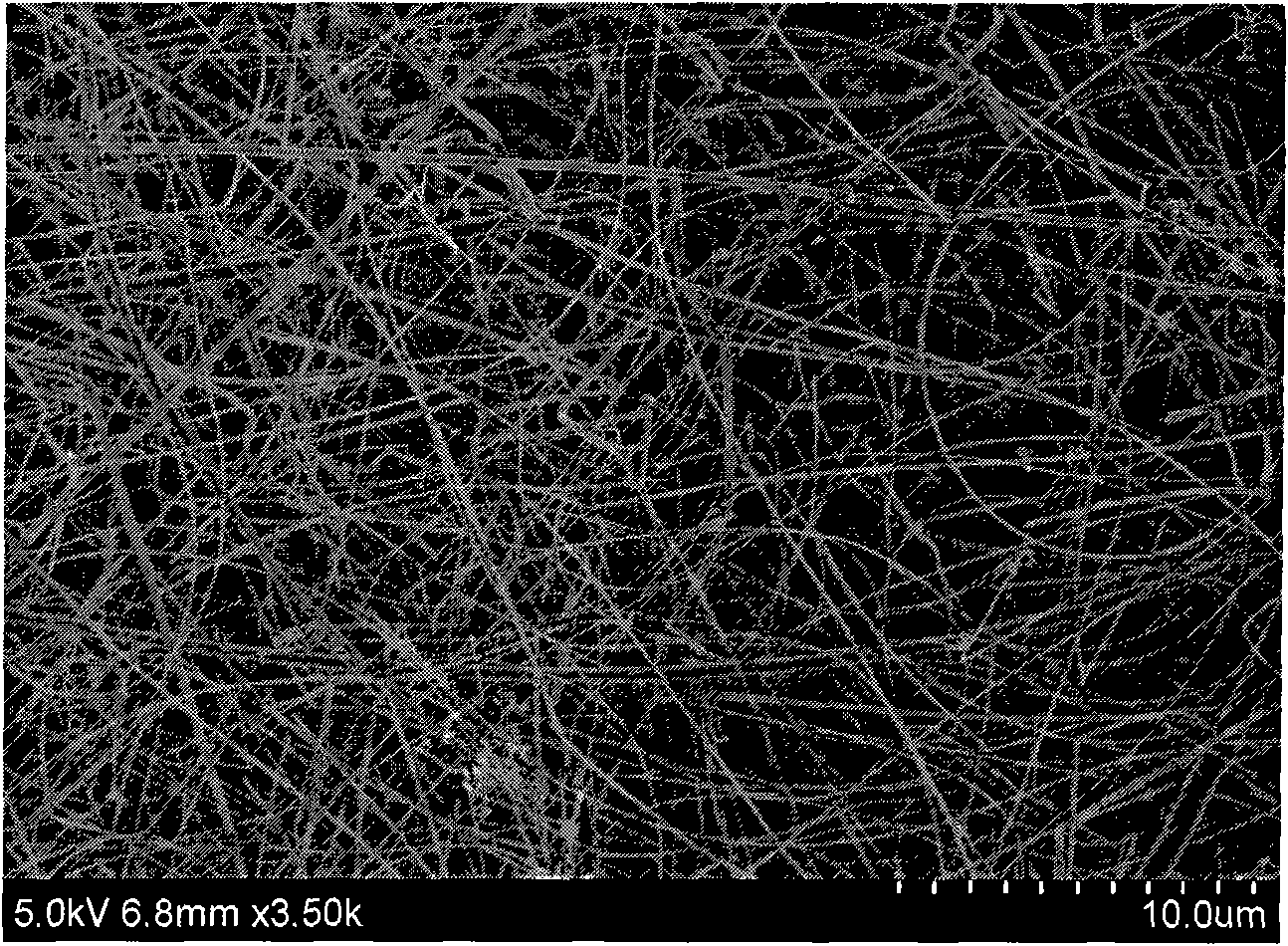

[0025] figure 1 It is a scanning electron micrograph of the product of Example 1.

Embodiment 2

[0027] The present embodiment is different from Example 1 in that in step 1, 36.8% industrial silicon powder (40 mesh, Si content > 99.3%) and 63.2% industrial flake-like expandable graphite are mechanically mixed in step 1; The temperature was raised to 1550°C at a rate of 8°C / min. Other steps are identical with embodiment 1. The SiC nanowire yield was 50%.

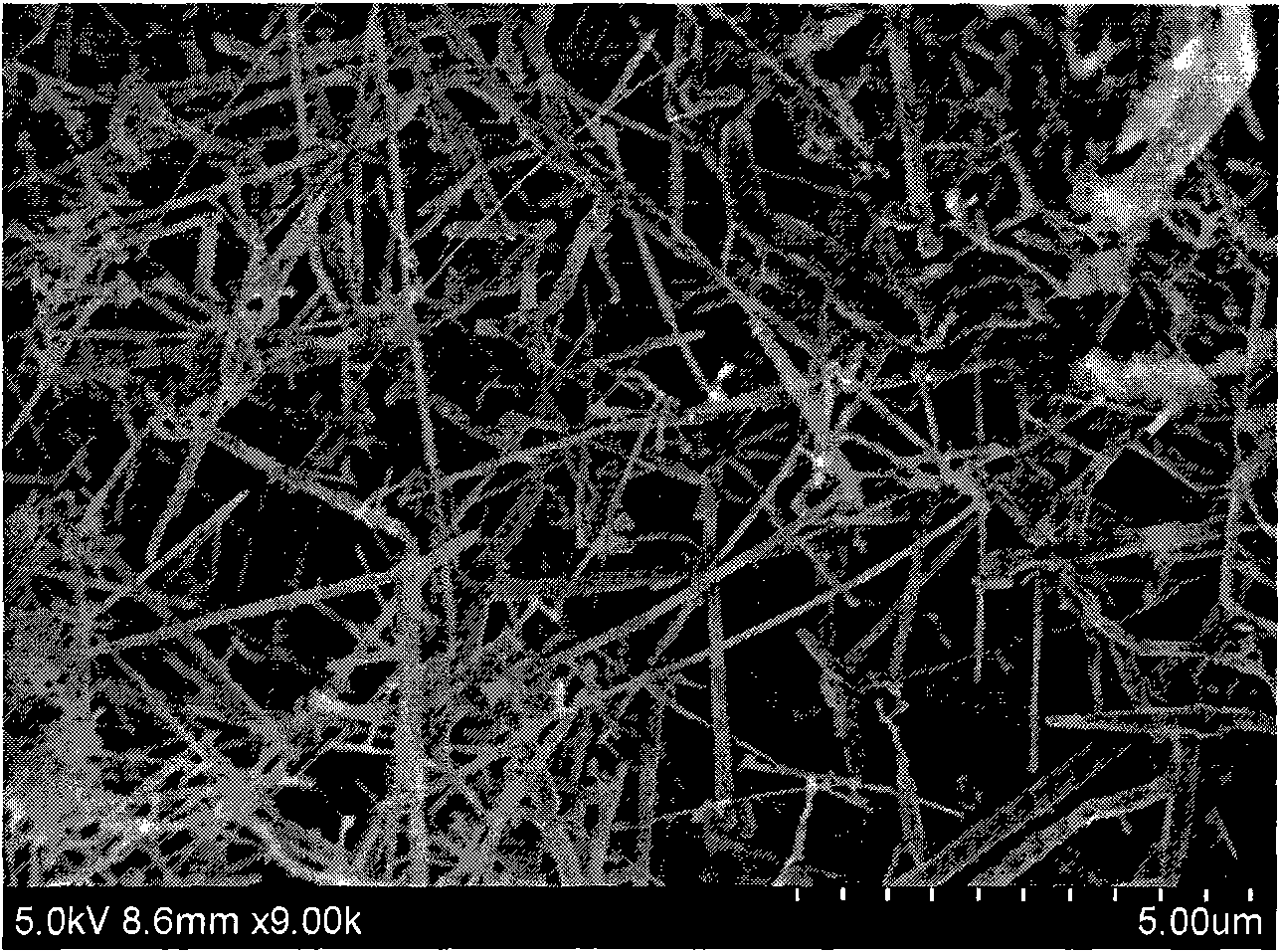

[0028] figure 2 It is the scanning electron micrograph of the product of embodiment 2.

Embodiment 3

[0030] The present embodiment is different from Example 1 in that in step 1, the mass percent is 62.5% industrial silica powder (200 orders, SiO 2 Content>99.5%) and mass percentage are 37.5% industrial flake-like expandable graphite to carry out mechanical mixing; In step 2, vacuumize to 10Pa to get rid of oxygen; In step 3, fill argon as protective gas, make the pressure in the furnace be 10 2 Pa; in step 4, the temperature was raised to 1700° C. at a rate of 15° C. / min, and kept for 1 hour, and the pressure in the furnace was kept below 0.25 MPa throughout the preparation process. Other steps are identical with embodiment 1. The SiC nanowire yield was 52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com