High-oil emulsified waste lye treatment agent and use process thereof

A technology of waste lye and treatment agent, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as difficulty in promotion, secondary pollution, and difficulty in stable operation. , to achieve the effect of stable and reliable process, ensure stable operation and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 2

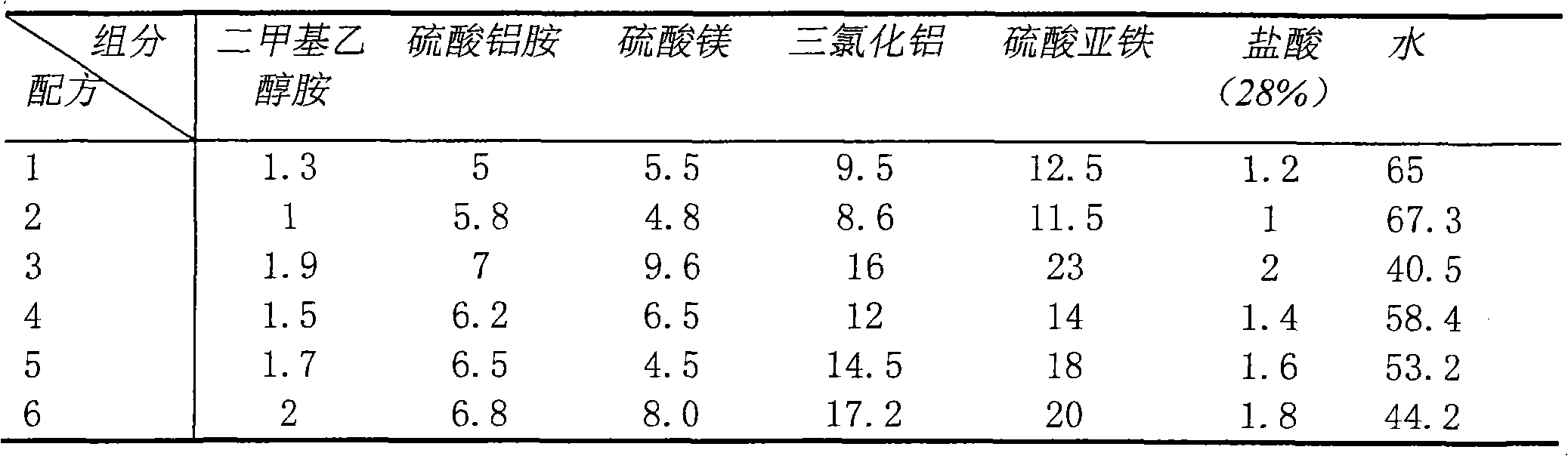

[0019] Preparation Example 2 of F regulator: According to formula 2 in the above table, take each component and repeat the step 1 of Preparation Example 1 of F regulator. The finished product is light yellow liquid with a pH value of 3.2.

preparation Embodiment 3

[0020] Example 3 of preparation of F regulator: according to formula 3 in the above table, each component was taken and the steps of Example 1 of preparation of F regulator were repeated. The finished product was a light yellow liquid with a pH value of 2.3.

preparation Embodiment 4

[0021] Preparation Example 4 of F Conditioner: Take each component according to formula 4 in the above table and repeat the step 1 of Preparation Example 1 of F Conditioner. The finished product is light yellow liquid with a pH value of 2.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com