Preparation method for preparing titanium dioxide photochemical catalyst by ionic liquid

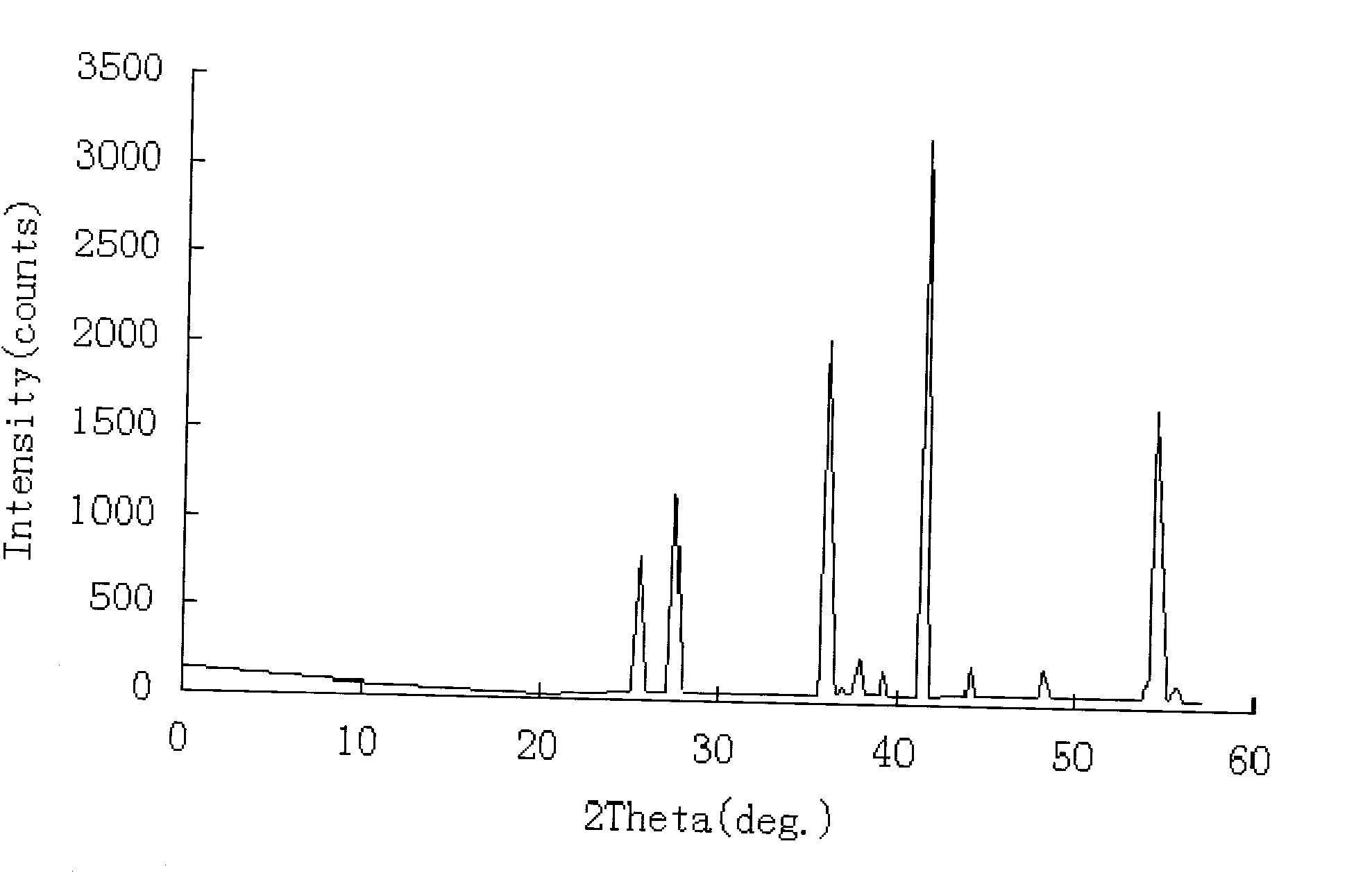

A technology of titanium dioxide and photocatalyst, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limitation, high recombination rate of photogenerated electrons and holes, low photon quantum efficiency, etc., and achieve crystallization Good, the wavelength range of excitation light is increased, and the particle size is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

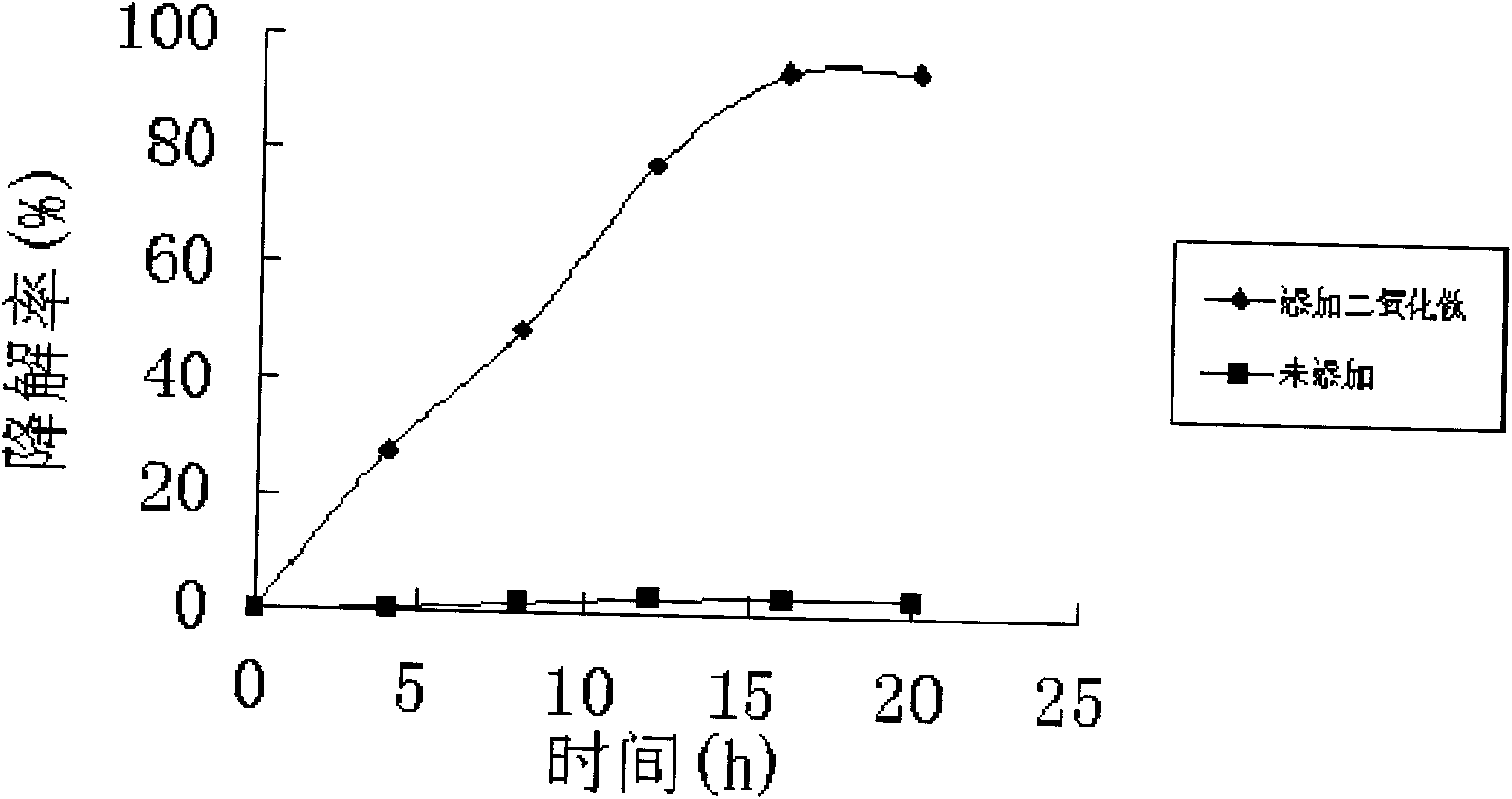

Examples

Embodiment 1

[0023] The high-efficiency titanium dioxide photocatalyst of the present embodiment is made up of following raw material by volume percentage:

[0024] 45% absolute ethanol, 35% butyl titanate, 13% 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, 5% distilled water, 1.6% acetylacetone, mass fraction of 20% to 22% Concentrated hydrochloric acid 0.4%.

[0025] The preparation method of this embodiment:

[0026] (1) Add 25ml of absolute ethanol, 35ml of butyl titanate and 1.6ml of acetylacetone in sequence into a reaction kettle with appropriate volume and mechanical stirring, and stir for 1 hour to obtain solution A.

[0027] (2) In another suitable volume reactor with mechanical stirring, add dehydrated alcohol 20ml, 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid 13ml, distilled water 5ml and concentrated hydrochloric acid ( The mass fraction is 20%~22%) 0.4ml, stirred for 0.5 hours to obtain solution B.

[0028] (3) Slowly pour solution B into sol...

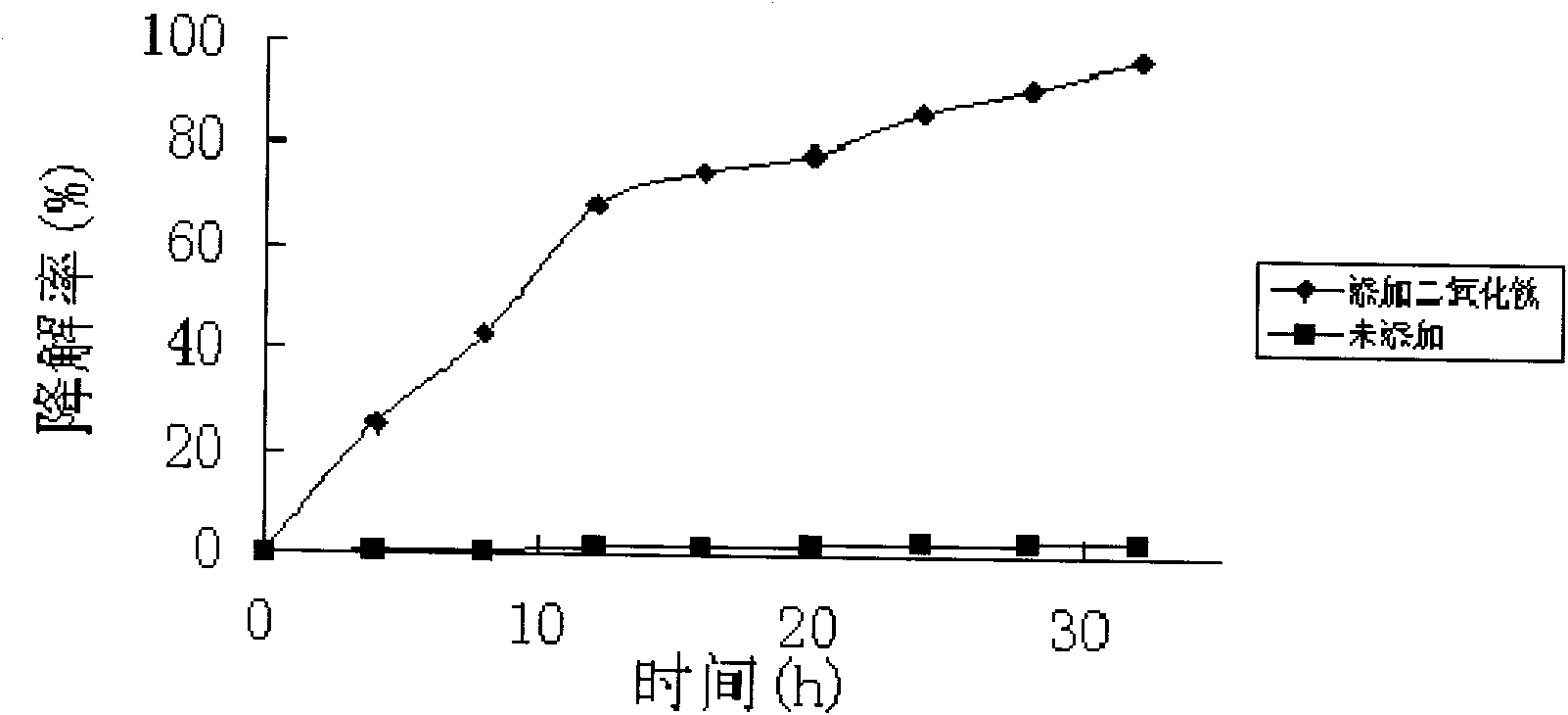

Embodiment 2

[0030] The high-efficiency titanium dioxide photocatalyst of the present embodiment is made up of following components by volume percentage:

[0031] 46% of absolute ethanol, 34% of butyl titanate, 14% of 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, 4.8% of distilled water, 1% of acetylacetone, concentrated hydrochloric acid (mass fraction is 20%~ 22%) 0.2%.

[0032] The preparation method of this embodiment:

[0033] (1) Add 26ml of absolute ethanol, 34ml of butyl titanate and 1ml of acetylacetone in sequence into a reaction kettle with appropriate volume and mechanical stirring, and stir for 1 hour to obtain solution A.

[0034] (2) Add 20ml of dehydrated ethanol, 14ml of 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, 4.8ml of distilled water and concentrated hydrochloric acid to another reactor with appropriate volume and mechanical stirring (Mass fraction is 20%-22%) 0.2ml, stirred for 0.5 hours to obtain solution B.

[0035] (3) Slowly p...

Embodiment 3

[0037] The high-efficiency titanium dioxide photocatalyst of the present embodiment is made up of following components by volume percentage:

[0038] 48% of absolute ethanol, 34% of butyl titanate, 12% of 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, 4.6% of distilled water, 1.1% of acetylacetone, concentrated hydrochloric acid (mass fraction is 20%~ 22%) 0.3%.

[0039] The preparation method of this embodiment:

[0040] (1) Add 25ml of absolute ethanol, 34ml of butyl titanate and 1.1ml of acetylacetone in sequence into a reaction kettle with appropriate volume and mechanical stirring, and stir for 1 hour to obtain solution A.

[0041] (2) Add 23ml of dehydrated ethanol, 13ml of 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, 4.6ml of distilled water and concentrated hydrochloric acid to another reactor with appropriate volume and mechanical stirring (Mass fraction is 20%-22%) 0.3ml, stirred for 0.5 hours to obtain solution B.

[0042] (3) Slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com