Surface gaseous penetration modification method of nanometer titanium dioxide film photocatalyst

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of low hydrogen production efficiency of titanium dioxide thin films, and achieve improved performance, improved efficiency, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

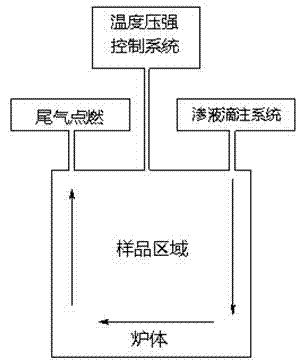

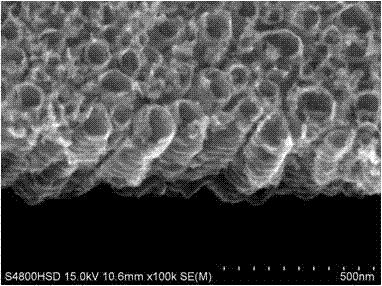

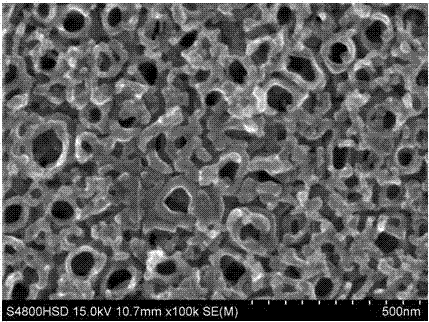

[0016] Specific embodiment 1: The nano-titanium dioxide thin film photocatalyst surface vapor phase diffusion modification method of the present embodiment is realized through the following steps: 1. Prepare a nano-titanium dioxide thin film on a titanium substrate: pretreat the titanium substrate to remove the surface oxide film, Then put the pretreated titanium substrate as the working electrode in the electrolyte, and the copper sheet as the counter electrode, control the reaction voltage to 10~30V, and carry out constant voltage anodization for 20~120min, that is, obtain nano-titanium dioxide film on the titanium substrate, The electrolyte composition is: 5~6g / L NaF and 2%~5% H 3 PO 4 Solution, the solvent is water; 2. Heat the carburizing furnace to 500~800°C, keep it warm, then drop methanol into the carburizing furnace, stop adding methanol after continuing to drop for 10~30min, and then put the Put the titanium matrix on the sample holder of the carburizing furnace, a...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium substrate in step 1 is commercially pure titanium, TC4 titanium alloy, titanium-nickel alloy or titanium-niobium alloy. Other steps and parameters are the same as those in Embodiment 1.

[0020] In this embodiment, the commercially pure titanium is TA1 or TA2.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the reaction voltage is controlled to be 15-25V. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com