Preparation method of antibacterial peptide gene engineering strain

A technology of genetically engineered strains and antimicrobial peptides, applied in the field of preparation of genetically engineered strains of antimicrobial peptides, can solve the problems of high production costs, small quantities, and inability to meet the needs of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

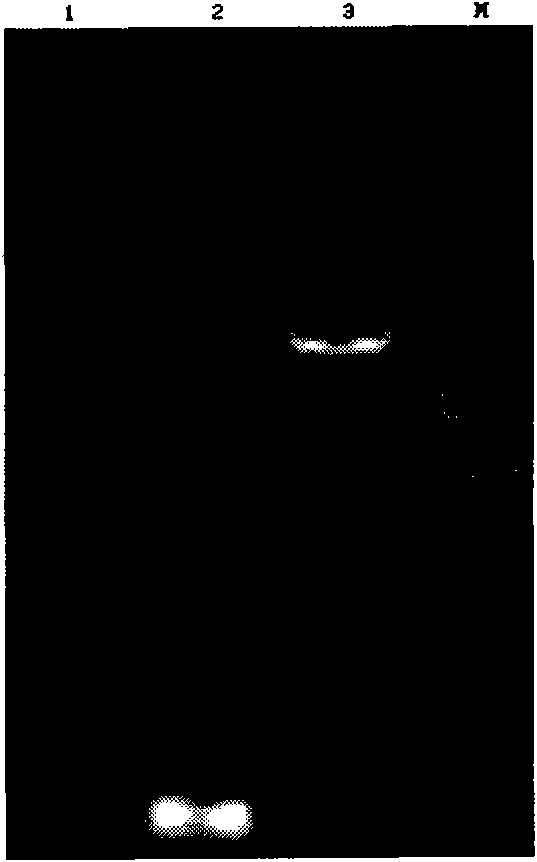

Image

Examples

preparation example Construction

[0019] The preparation method of antimicrobial peptide genetically engineered bacterial strain comprises the following steps:

[0020] 1) According to the antimicrobial peptide Cecropin A gene sequence with the registration number AAA29185, the whole sequence was synthesized, and at the same time, histidine tag sequence and restriction enzyme cutting sites NotI and XhoI were respectively introduced to obtain the antimicrobial peptide Cecropin A gene synthesis product;

[0021] 2) Cloning the antimicrobial peptide Cecropin A gene synthesis product into the pGEM-T vector to obtain the recombinant vector pGEM-T-CEC, and transferring the recombinant vector pGEM-T-CEC into Escherichia coli DH5α to obtain DH5α (pGEM-T-CEC) strains;

[0022] 3) Extract the recombinant vector pGEM-T-CEC plasmid from the DH5α (pGEM-T-CEC) strain, use NotI and XhoI to double-digest the plasmid pGEM-T-CEC to obtain the target fragment Cecropin A; similarly digest the yeast shuttle vector pPIC9k to make ...

Embodiment 1

[0032] 1. Synthesis of antibacterial peptide Cecropin A gene sequence, introducing enzyme cutting sites NotI and XhoI during design:

[0033] ctcgagaagtggaagttgtttaagaaaattgaaaaggttggtcaaaacattagagatggtattattAaggctggtccagctgttgctgtttgttggtcaagctactcaaattgctaaggcggccgc

[0034] (a) Sequence features:

[0035] Length: 125 base pairs

[0036] Type: nucleic acid

[0037] Chain type: double chain

[0038] Topology: Linear

[0039] (b) Molecular type: double-stranded DNA

Embodiment 2

[0041] Ligation of Antimicrobial Peptide Cecropin A Gene Sequence and pGEM-T Intermediate Vector

[0042](1) The synthetic product was cloned into the pGEM-T vector: take 1 μg of the antimicrobial peptide Cecropin A prepared in Example 1 and connect it to the T vector according to the following system (using Takara cloning kit)

[0043] 10×ligation Buffer 1μL

[0044] Cecropin A 5 μL

[0045] pGEM-T vector 1 μL

[0046] T4 DNA ligase 1 μL

[0047] ddH2O Up to 10μL

[0048] (2) Transform the recombinant vector pGEM-T-CEC into Escherichia coli DH5α:

[0049] a) Immediately place the cryopreserved E. coli DH5α competent cells in an ice bath, then add 15 μL of the ligation product to 100 μL of the competent cells, ice bath for 30 minutes, and then quickly place them in a water bath at 42°C for 90 seconds for heat shock , placed in an ice bath for 2 minutes immediately, then added to 800 μL of SOC medium, incubated at 170 rpm at 37°C for 50 minutes, then centrifuged the cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com