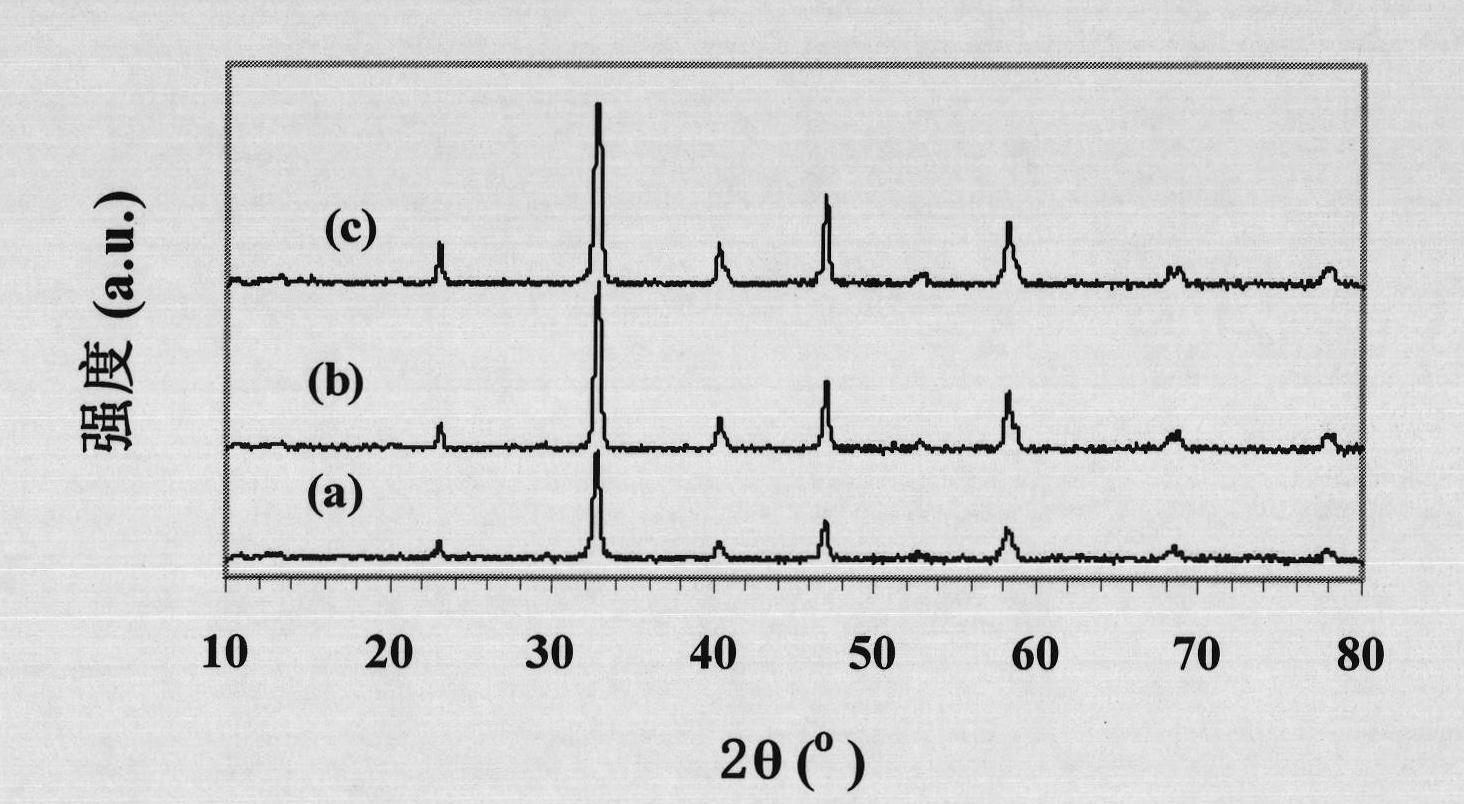

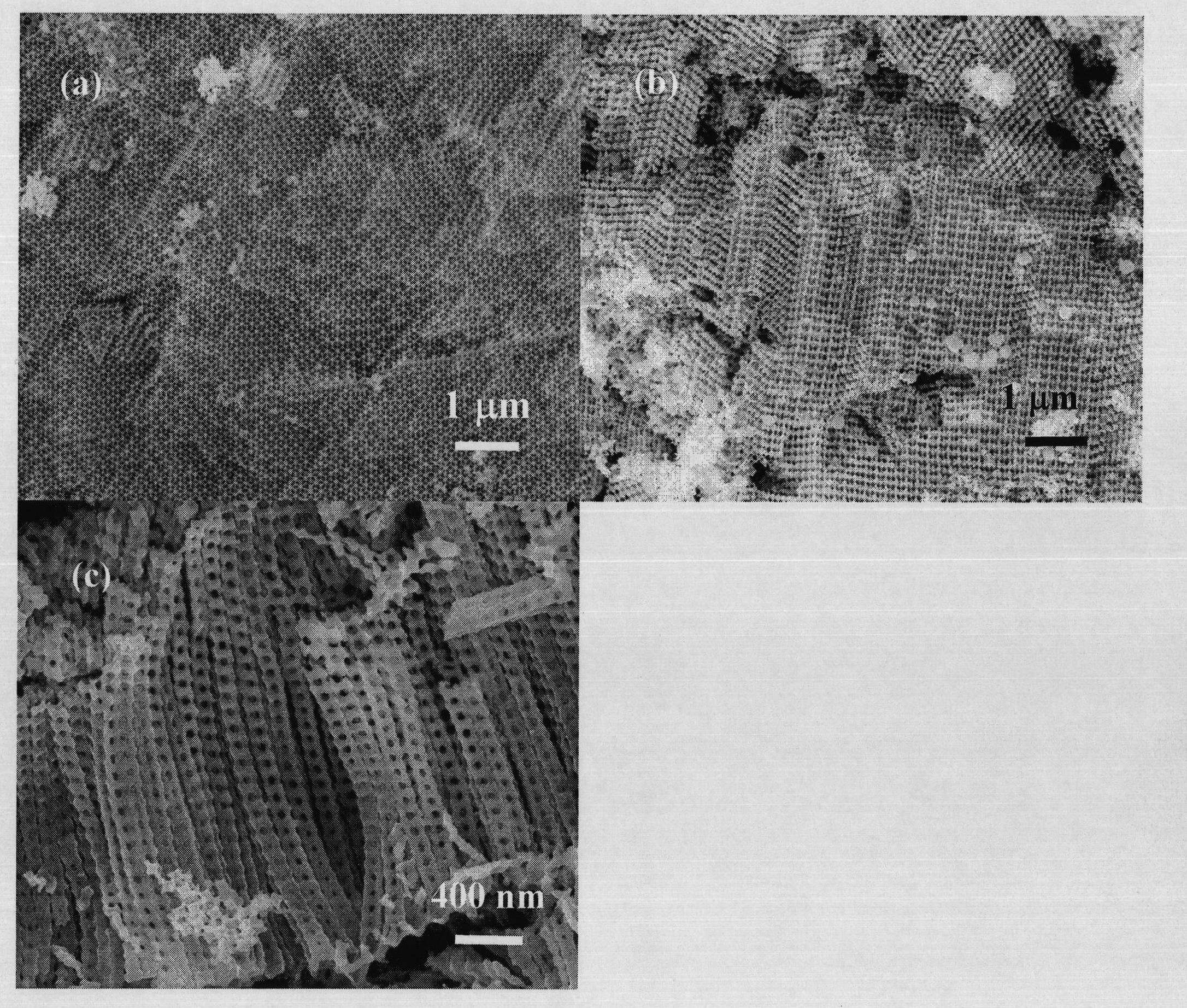

Polyethylene glycol and citric acid auxiliary template method of three-dimensional ordered macroporous and chain LaMnO3

A three-dimensional ordered, colloidal crystal template technology, applied in the direction of manganate/permanganate, etc., to achieve good application prospects, good catalytic activity, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: take by weighing 12.99gLa (NO 3 ) 3 ·6H 2 O and 8.32ml mass fraction are 50% Mn(NO 3 ) 2The aqueous solution was placed in a 50 mL beaker, 3 mL of polyethylene glycol 400 was added, and after 4 hours of magnetic stirring, a homogeneous solution was formed, and then 14 mL of methanol (46% by volume of methanol) was added. The above mixture was poured into a 50 mL beaker containing 1 g of polymethyl methacrylate (PMMA). In order to keep the original orderly arrangement of PMMA, do not stir during the pouring process of this mixed solution. After the mixture was impregnated with PMMA for about 5 hours, the sample obtained by suction filtration was dried at room temperature for 12 hours, and then the sample was loaded into a magnetic boat and placed in a tube furnace. 2 Under the atmosphere (20mL / min), the temperature was raised from room temperature to 500°C at a rate of 1°C / min and kept at this temperature for 3 hours. The rate of min is increased to 7...

Embodiment 2

[0019] Embodiment 2: take by weighing 15.16g La(NO 3 ) 3 ·6H 2 O, 8.4g citric acid and 9.67ml mass fraction are 50% Mn(NO 3 ) 2 The aqueous solution was placed in a 50 mL beaker, 5 mL of ethylene glycol was added, and after magnetic stirring for 4 hours, a uniform solution was formed, and then 13 mL of methanol (36% by volume of methanol) was added. The above mixture was poured into a 50mL beaker filled with 1g PMMA. In order to keep the original orderly arrangement of PMMA, do not stir during the pouring process of this mixed solution. After the mixture was soaked in PMMA for about 5 hours, the sample obtained by suction filtration was dried at room temperature for 12 hours, and then the sample was loaded into a magnetic boat and placed in a tube furnace. 2 Under the atmosphere (20mL / min), the temperature was raised from room temperature to 500°C at a rate of 1°C / min and kept at this temperature for 3 hours. The rate of min increased to 750 °C and kept at this temperatu...

Embodiment 3

[0020] Embodiment 3: take by weighing 12.99g La(NO 3 ) 3 ·6H 2 O and 8.32ml mass fraction are 50% Mn(NO 3 ) 2 The aqueous solution was placed in a 50 mL beaker, 5 mL of polyethylene glycol 400 was added, and after magnetic stirring for 4 hours, a homogeneous solution was formed, and then 12 mL of methanol (40% by volume of methanol) was added. The above mixture was poured into a 50mL beaker filled with 1g PMMA. In order to keep the original orderly arrangement of PMMA, do not stir during the pouring process of this mixed solution. After the mixture was impregnated with PMMA for about 5 hours, the sample obtained by suction filtration was dried at room temperature for 12 hours, and then the sample was loaded into a magnetic boat and placed in a tube furnace. 2 Under the atmosphere (20mL / min), the temperature was raised from room temperature to 500°C at a rate of 1°C / min and kept at this temperature for 3 hours. The rate of min increased to 750°C and kept at this temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com