Method for preparing naphthalene-doped MgB2 superconductive single-core wire

A superconducting, single-core technology, applied in the field of preparation of MgB2 superconducting wire, can solve the problems of limited improvement of critical current density and irreversible field of wire, reduced connectivity between grains, easy agglomeration of nano C powder, etc. Through pinning force, easy control, good die connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

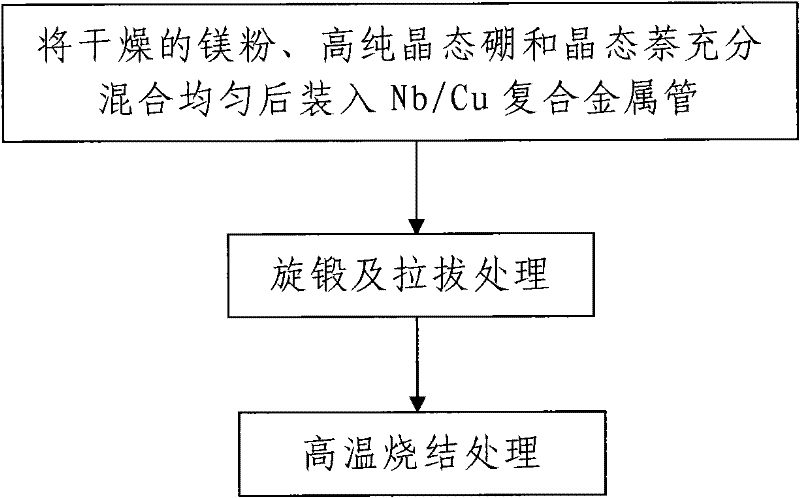

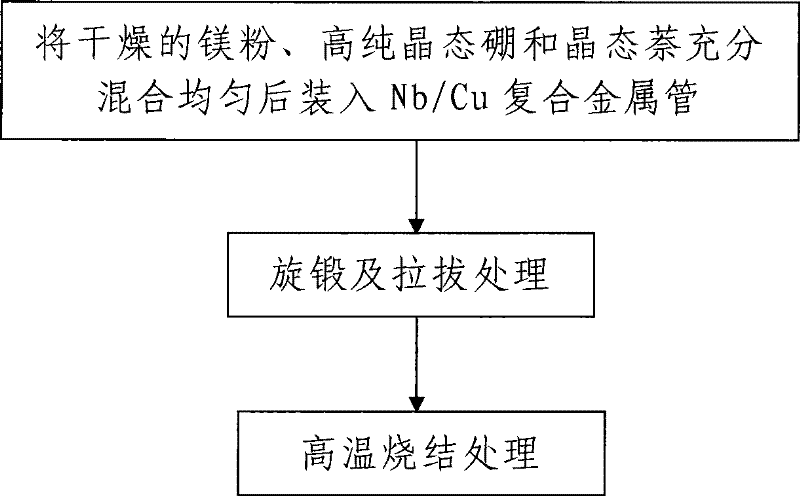

[0024] Such as figure 1 A naphthalene-doped MgB shown 2 A method for preparing a superconducting single-core wire, comprising the following steps:

[0025] Step 1, tube loading: First, fully mix dry magnesium powder and high-purity crystalline boron powder according to the ratio of atomic number of 1:2 to obtain a mixture; then add crystalline naphthalene to the mixture and pass through The combined material is obtained after fully mixing and grinding evenly, and the mass percentage of the added crystalline naphthalene in the mixed material is 2% to 15%; subsequently, the combined material is put into a Nb / Cu composite metal tube to obtain A tube-packing complex: the Nb / Cu composite metal tube is composed of an inner tube made of Nb material and an outer tube coaxially sleeved on the outside of the inner tube and made of Cu material.

[0026] During actual preparation, the time for thorough mixing and grinding is 0.5-1.0 h. The purity of the high-purity crystalline boron po...

Embodiment 1

[0030] In this example, naphthalene doped with MgB 2 When the superconducting single-core wire is prepared, the preparation process is as follows:

[0031] Step 1, tube loading: first, fully mix dry magnesium powder and high-purity crystalline boron powder according to the ratio of atomic numbers of 1:2 to obtain a mixture; after that, add crystalline naphthalene to the mixture After fully mixing and grinding evenly, the combined material is obtained, and the added crystalline naphthalene accounts for 2% by mass of the mixed material; subsequently, the combined material is packed into a Nb / Cu composite metal tube to obtain a packed Tube composite body; the Nb / Cu composite metal tube is composed of an inner tube made of Nb material and an outer tube coaxially sleeved on the outside of the inner tube and made of Cu material.

[0032] During actual preparation, the time for thorough mixing and grinding is 0.5 h. The mass purity of the high-purity crystalline boron powder is 99.99...

Embodiment 2

[0038] In this example, the difference from Example 1 is that when the tube is installed in step 1, the mass percentage of crystalline naphthalene added in the mixture accounts for 5% of the mixture, and the time for fully mixing and grinding is 0.8h When carrying out swaging and drawing processing in the step 2, adopt swaging machine and drawing machine successively to carry out swaging and drawing processing to the packing complex body described in step 1, pass processing rate is 15%, And obtain MgB with a diameter of Φ1.0mm 2 Preliminary product of superconducting single-core wire; when performing high-temperature sintering in step 3, the sintering temperature is 800°C, the heating rate is 20°C / min, and the holding time is 1.5h. In this embodiment, the remaining method steps and process parameters are the same as those in Embodiment 1.

[0039] The final MgB 2 The finished superconducting single-core wire has the characteristics of small hole size, good grain connectivity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com