Method for preparing nano silver particles

A technology of nano-silver particles and silver nitrate, which is applied in the field of preparation of nano-silver particles, can solve the problems of high cost, low production efficiency of physical methods, and high energy consumption, and achieve the effects of small particle size, mild reaction conditions, and simple separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

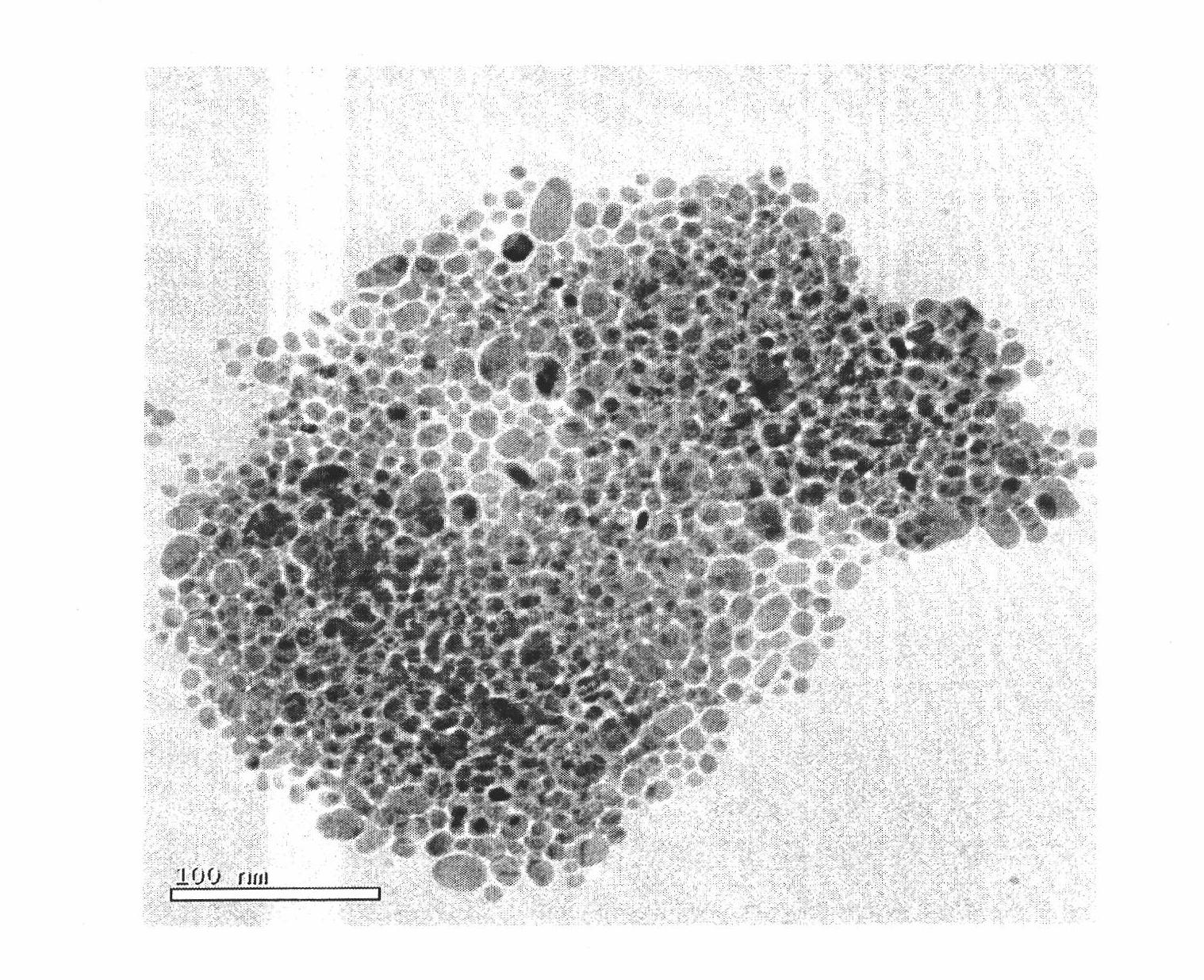

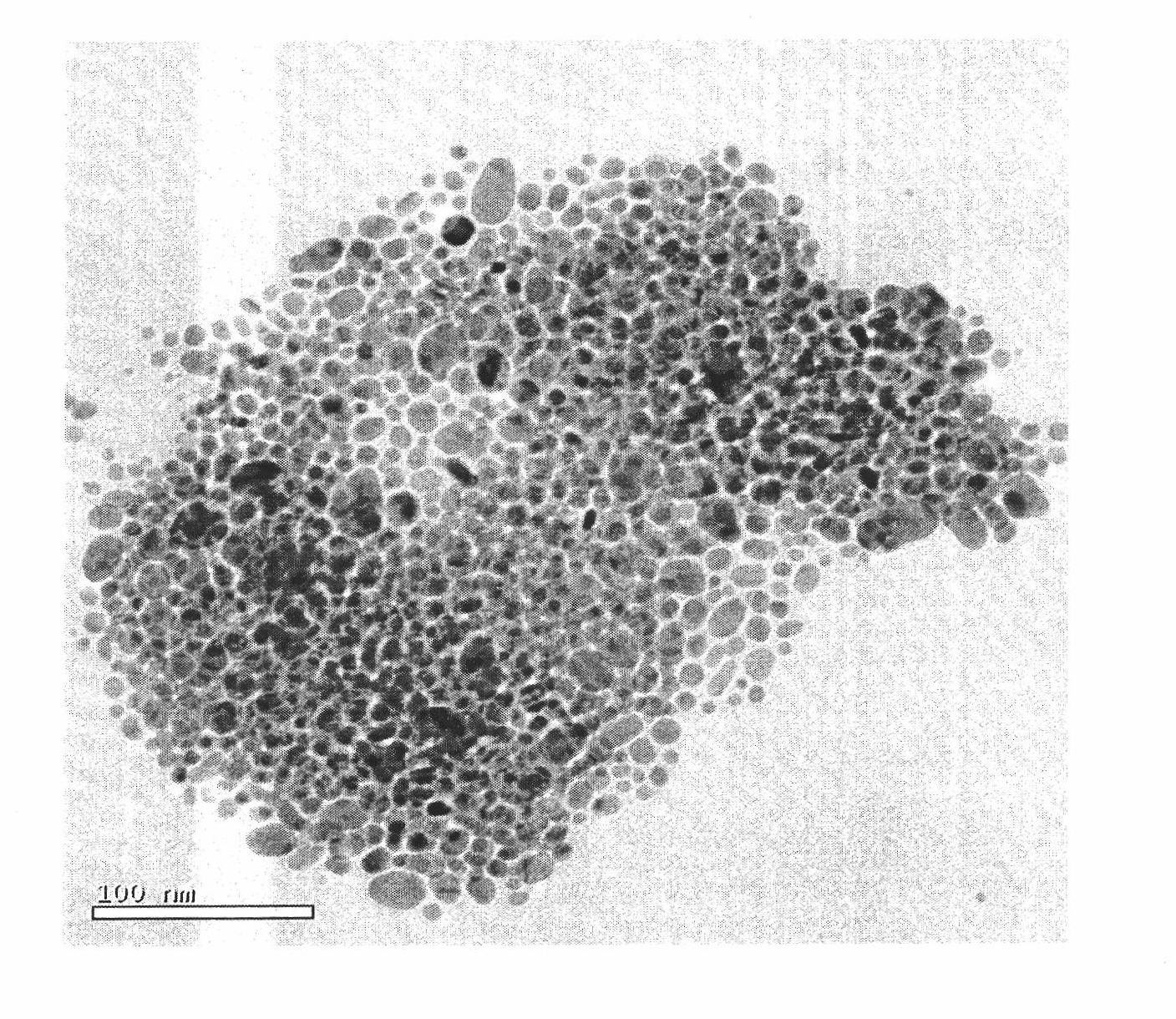

Image

Examples

Embodiment 1

[0016] 60g of silver nitrate is dissolved in 500mL of water, and 60mL of 25% concentrated ammonia water is added thereto to form a silver-ammonia complex solution, 15g of lauric acid is added to the solution, and 120mL of concentrated ammonia is added under stirring to adjust its pH value to promote Dissolution of lauric acid. After the lauric acid is completely dissolved, increase the stirring speed to 800rpm, add dropwise 400mL aqueous solution containing 4g of sodium borohydride, the whole dropping process lasts for 30min, continue to stir and react for 20min after the dropping is completed, and the whole reaction process is maintained at room temperature . Thereafter, the stirring speed was reduced to 100 rpm, and 200 mL of 20% (V / V) phosphoric acid was slowly added thereto. After the addition, it was allowed to stand and filtered to obtain a black solid. The obtained black solid was washed successively with 250 mL of methanol and 250 mL of ethanol, and filtered again to...

Embodiment 2

[0018] 100g of silver nitrate was dissolved in 1000mL of water, and 125mL of 40% methylamine aqueous solution was added thereto to form a silver-ammonia complex solution, and 16g of sodium n-octoate was added to the solution, and stirred to completely dissolve the sodium n-octoate. Thereafter, the stirring speed was increased to 500 rpm, and 48 g of 37% formaldehyde aqueous solution was added dropwise thereto. The whole dropping process lasted for 30 minutes, and the stirring reaction was continued for 60 minutes after the dropping was completed. Reduce the stirring speed to 200 rpm, and slowly inject 150 mL of 25% (V / V) phosphoric acid into the system. After the addition, it was allowed to stand and filtered to obtain a black solid. The obtained black solid was washed successively with 250 mL of ethanol and 250 mL of acetone, and filtered again to obtain "wet" silver nanoparticles, which were dried in a vacuum to obtain about 45 g of silver nanoparticles.

Embodiment 3

[0020] Dissolve 60g of silver nitrate in 1200mL of water, add 90g of ethylenediaminetetraacetic acid disodium salt (EDTA) to it to form a silver complex solution, add 15g of lauric acid to the above solution, and add 100g of 10% NaOH aqueous solution under stirring Adjust its pH to facilitate the dissolution of lauric acid. After the lauric acid is completely dissolved, increase the stirring speed to 1200rpm, and dropwise add 20mL of 40% hydrazine hydrate dropwise. The whole dropping process lasts for 30 minutes. After the dropping is completed, continue stirring for 20 minutes. room temperature. Thereafter, the stirring speed was reduced to 150 rpm, and 250 mL of 15% (V / V) phosphoric acid was slowly added thereto. After the addition, it was allowed to stand and filtered to obtain a black solid. The obtained black solid was washed twice with 500 mL of ethanol (250 mL each time), and filtered again to obtain "wet" silver nano-particles. After vacuum drying, about 27 g of silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com