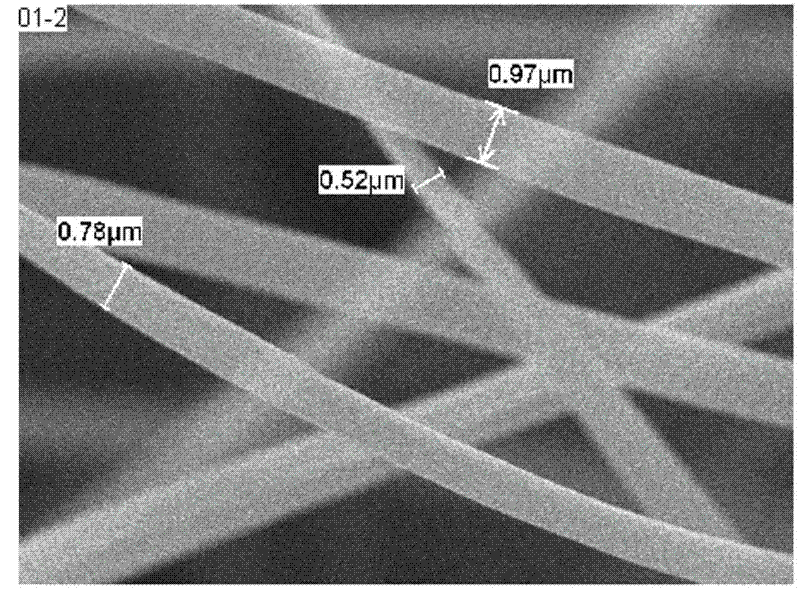

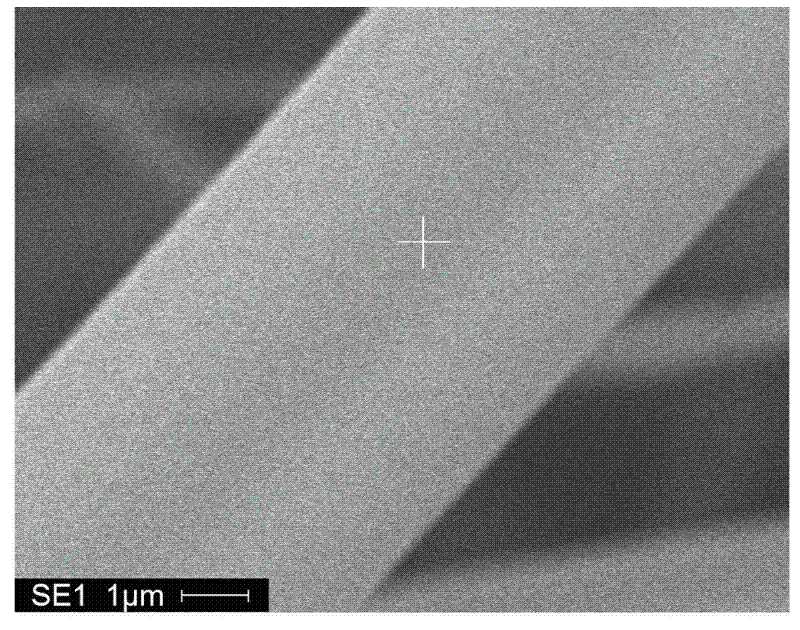

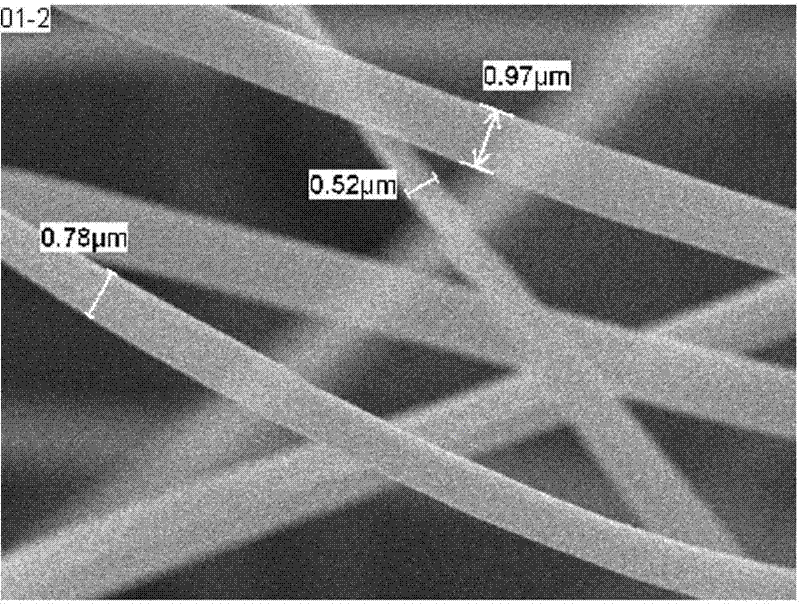

Preparation method of superfine zirconia/silicon carbide composite fibers

A technology of ultra-fine zirconia and composite fibers, which is applied in fiber treatment, spinning solution preparation, filament/wire forming, etc., can solve the problems of large diameter of zirconium-containing silicon carbide fibers, and achieve good spinnability and specific surface area Great, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of spinning solution: polycarbosilane solid (softening point 200~220°C) and 85% tetrabutyl zirconate n-butanol solution according to the mass ratio of polycarbosilane and tetrabutyl zirconate to 9 : 1; co-dissolve in xylene, prepare polycarbosilane / tetrabutyl zirconate solution according to the ratio of polycarbosilane and solvent (xylene and n-butanol) at 1.1:1g / ml, and disperse with ultrasonic for 30 minutes;

[0020] (2) Electrospinning: Spinning conditions: the inner diameter of the needle is 0.6mm, the voltage is 15kV, the distance of the wire is 20cm, the feeding rate is 20μl / min, and the aluminum foil is collected to obtain polycarbosilane / tetrabutyl zirconate fibrils;

[0021] (3) Air pre-oxidation: put the above-mentioned fibrils in an oxidation furnace, raise the temperature to 220°C at 20°C / h in an oxidative atmosphere, and keep it at this temperature for 1 hour, and obtain infusible polycarbonate after cooling to room temperature Silane / tetra...

Embodiment 2

[0028] (1) Preparation of spinning solution: polycarbosilane solid (softening point 200~220°C) and 85% tetrabutyl zirconate n-butanol solution according to the mass ratio of polycarbosilane and tetrabutyl zirconate to 11 : 1 co-dissolve in xylene, prepare polycarbosilane / tetrabutyl zirconate solution according to the ratio of polycarbosilane and solvent (xylene and n-butanol) at 1.2:1 g / ml, and disperse by ultrasonic for 30 minutes;

[0029] (2) Electrospinning: Spinning conditions: needle inner diameter 1.0mm, voltage 20kV, take-up distance 25cm, feed rate 30μl / min, aluminum foil take-up, and produce polycarbosilane / tetrabutyl zirconate fibrils;

[0030] (3) Air pre-oxidation: put the above-mentioned fibrils in an oxidation furnace, raise the temperature at 20°C / h in an oxidative atmosphere, keep it at 210°C for 1 hour, and obtain infusible polycarbosilane / zirconic acid after cooling to room temperature tetrabutyl fiber;

[0031] (4) High-temperature firing: put the above-me...

Embodiment 3

[0033] (1) Preparation of spinning solution: polycarbosilane solid (softening point: 200~220°C) and 85% n-butanol solution of tetrabutyl zirconate, according to the mass ratio of polycarbosilane to tetrabutyl zirconate Co-dissolve in xylene at 1:1, polycarbosilane / solvent (xylene and n-butanol) ratio is 1.3:1g / ml to prepare polycarbosilane / tetrabutyl zirconate solution, and disperse with ultrasound for 30 minutes;

[0034] (2) Electrospinning: Spinning conditions: the inner diameter of the needle is 1.2mm, the voltage is 25kV, the wire collection distance is 15cm, the feeding rate is 40μl / min, and the aluminum foil is collected to obtain polycarbosilane / tetrabutyl zirconate fibrils;

[0035] (3) Air pre-oxidation: put the above-mentioned fibrils in an oxidation furnace, raise the temperature at 25°C / h in an oxidative atmosphere, and keep it at 200°C for 1.5 hours, and cool to room temperature to obtain infusible polycarbosilane / zirconic acid tetrabutyl fiber;

[0036] (4) Hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com