Method for preparing titanium-silicon-aluminum sol with photocatalytic property from blast furnace titanium slag

A technology of titanium slag and photocatalysis, applied in chemical instruments and methods, physical/chemical process catalysts, energy and wastewater treatment, etc., can solve problems such as human health and natural environmental hazards, occupying arable land area, and no treatment methods, etc., to achieve The effect of short purification treatment time, reducing a large amount of occupation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Mix the titanium slag that is ground to a particle size of less than 80 microns and sodium carbonate at a mass ratio of 1:1, place it in a high-temperature furnace for calcination at 1100°C for 2 hours, cool naturally, grind the material to a particle size of less than 80 microns, and then Mix with water according to the weight ratio of 1 part of material plus 10 parts and stir at room temperature for 120 minutes; after filtration and dissolution, the solution is ion-exchanged through a strong acidic cation exchange resin, and the solution drips from the bottom of the exchange column at a rate of every 2 1 drop per second, collect the solution after ion exchange, the solution contains ions of titanium, silicon and aluminum, remove the metal cations in the original solution, and adjust the pH of the solution to 0.5, 1, 1.5, 2, 2.5, that is, 5 parts of TiO were obtained 2 / SiO 2 / Al 2 o 3 Sol. .

[0029] Prepare 10mg / L, 20mg / L, 30mg / L, 40mg / L, 50mg / L solutions with me...

Embodiment 2

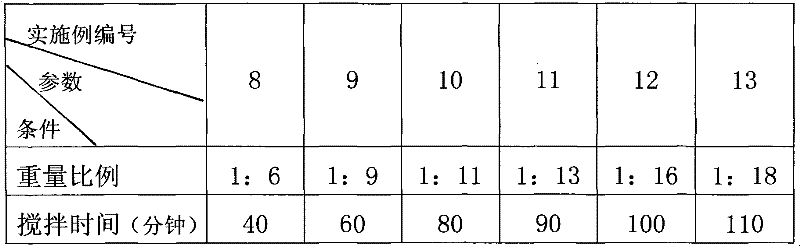

[0031] In the embodiment, the alkali uses sodium hydroxide or potassium hydroxide to replace sodium carbonate, the ratio of slag and alkali is in the range of 1: 0.5 to 1: 1.15, and the calcining temperature is in the range of 950°C to 1350°C; The block is ground in a mill until the particle size is less than 80 microns, then the ground fine powder is mixed in a weight ratio of 1:13 by fine powder: water and stirred for 100 minutes, then filtered, and the filter residue and filtrate are discarded. Ion exchange is carried out by strongly acidic cation exchange resin, and the pH value of the collected ion-exchanged solution is adjusted between 0.5 and 3 with dilute hydrochloric acid to obtain TiO 2 / SiO 2 / Al 2 o 3 Sol. The extraction rate of titanium, silicon and aluminum can reach more than 85% according to the experiment.

Embodiment 3

[0033] A method for preparing titanium-silicon-alumina sol with photocatalytic properties from blast furnace titanium slag is characterized in that it comprises the following steps:

[0034] a, grinding: the slag is placed in a mill (which can be a vibration mill or other prior art grinding equipment) and ground to a particle size of less than 80 microns to obtain slag powder;

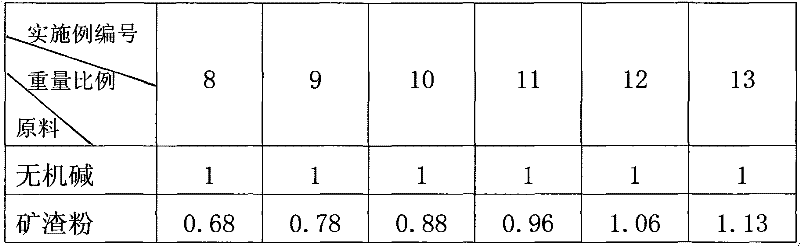

[0035] B, slag powder and alkali mixed ball milling: take inorganic alkali and slag powder according to the weight ratio of inorganic alkali: slag powder is 1: 0.66, put into the ball mill after mixing and grind, and grind to material particle diameter less than 60 microns, make mixed Powder;

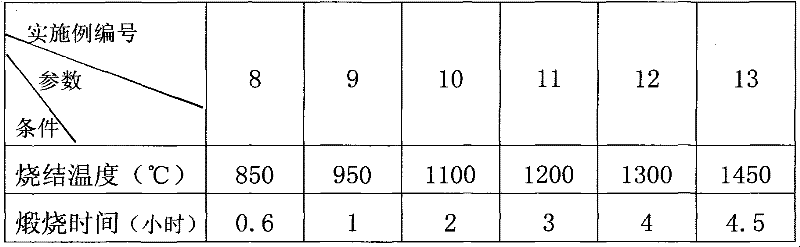

[0036] c. Calcination: In the case of high-temperature furnace under normal pressure, place the mixed powder at a sintering temperature of 800°C, heat-preserve and calcinate for 5 hours, and then cool naturally to room temperature;

[0037] d. Grinding: the calcined material is placed in a vibrating mill (or ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com