Hydrated matrix manufacturing and advanced treatment technology for biological treatment tail water of landfill percolate

A biological treatment and advanced treatment technology, applied in the direction of adsorption water/sewage treatment, oxidation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. High cost and other problems, to achieve the effect of simple process flow, reducing raw material investment costs, and reducing CODCr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the above implementation steps, in this embodiment:

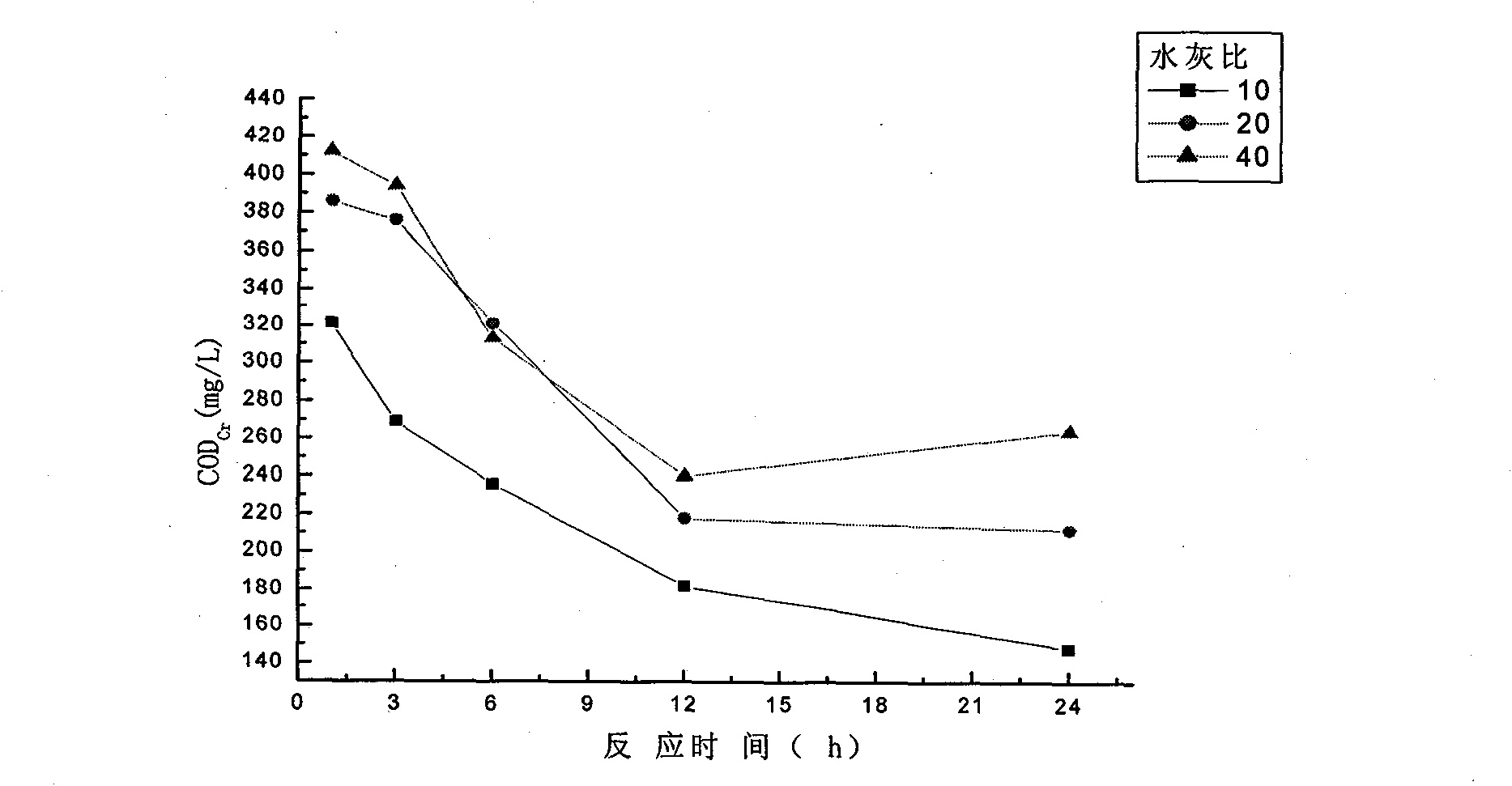

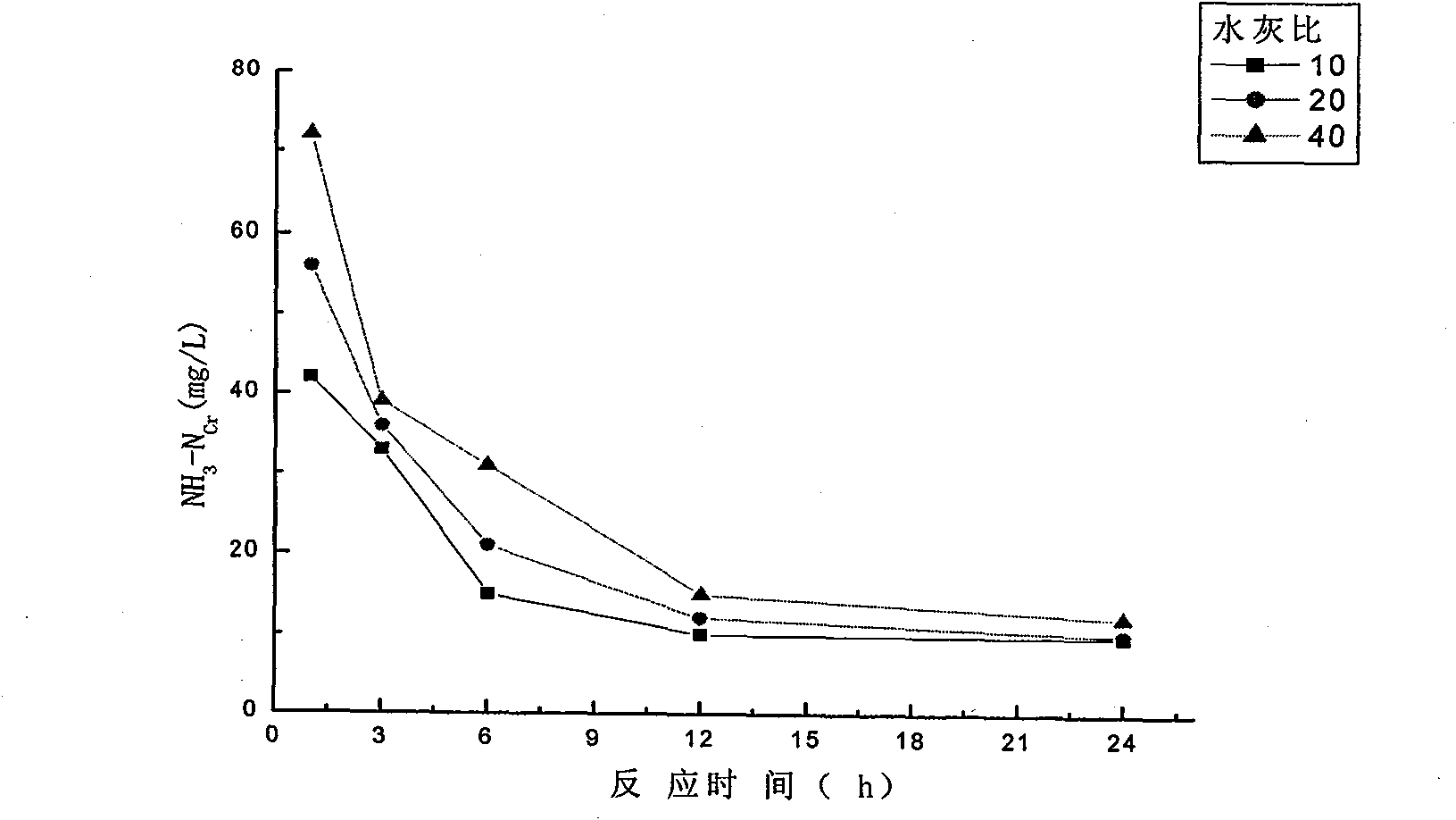

[0044] Filler: The designed water-cement ratio is 10:1, 20:1, 40:1 respectively, the hydration base is 12.5-50g, and the leachate tail water is fixed at 500mL, which is added to the reactor respectively, and the control speed is as low as possible, about 120r / min, react for 24 hours, let it settle for 2 hours, and take the supernatant to measure its water quality index.

[0045] The influent of the reactor is the effluent of the existing leachate treatment process of a tidal flat landfill in Shanghai, and its specific properties are shown in Table 1 below:

[0046] Table 1 Influent leachate tail water quality index (mg / L)

[0047] pH

[0048] From figure 1 It can be seen from the figure that the effect of cement on the treatment of tail water is very obvious. After treatment, the COD of tail water can be reduced to 148mg / L, and the removal rate is as high as 69.5%, which meets the secondary ...

Embodiment 2

[0050] The influent of the reactor is the effluent of the existing leachate treatment process of a tidal flat landfill in Shanghai, and its specific properties are shown in Table 1 below:

[0051] Table 2 Influent leachate tail water quality index (mg / L)

[0052] pH

COD

BOD 5

TOC

Conductivity (μs / cm)

NH 3 -N

NO 3 -N

TN

TP

8.03

569

3.691

164

869

174

259

489

6.472

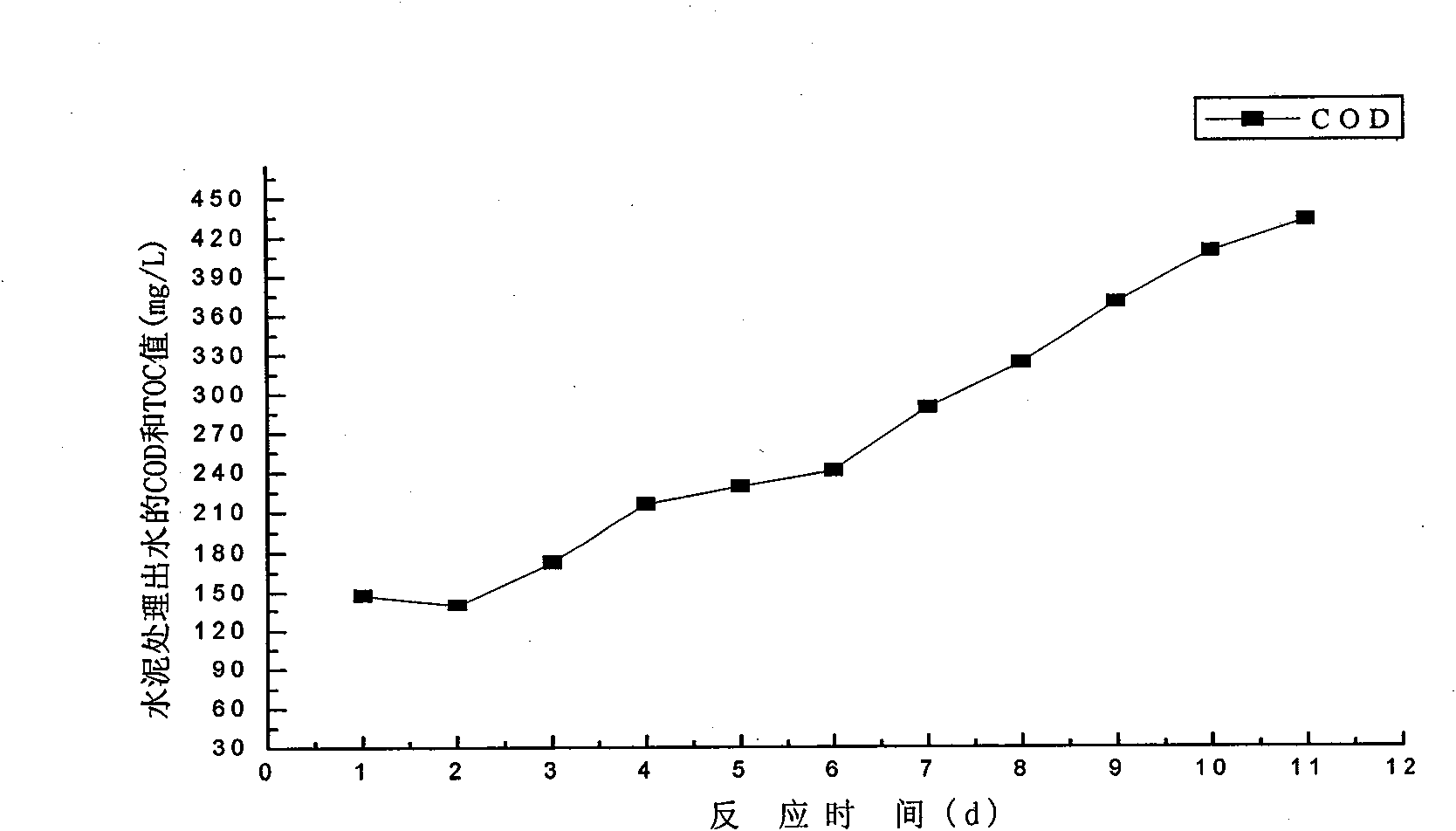

[0053] The water-cement ratio of the feed is 10:1, the speed is as low as possible, about 120r / min, reacted for 24 hours, allowed to settle for 2 hours, and took the supernatant to measure its water quality index.

[0054] The experimental results of continuous batch treatment show that, without replacing the reactive cement, the effluent COD can be kept below the national secondary discharge standard within 7 days, and below 200mg / L within 3 days. After 6d, the effluent COD began to rise rapidly ( image 3 ), indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com