Method for supplementing denitrifying carbon source by utilizing excess sludge ethanol-type fermentation

A denitrification carbon source and excess sludge technology, applied in biological sludge treatment, pyrolysis treatment sludge, anaerobic digestion treatment, etc., can solve the problems of increased operating costs, toxic and side effects of denitrification system, and insufficient denitrification carbon source To avoid the accumulation of phosphorus in the system and improve the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

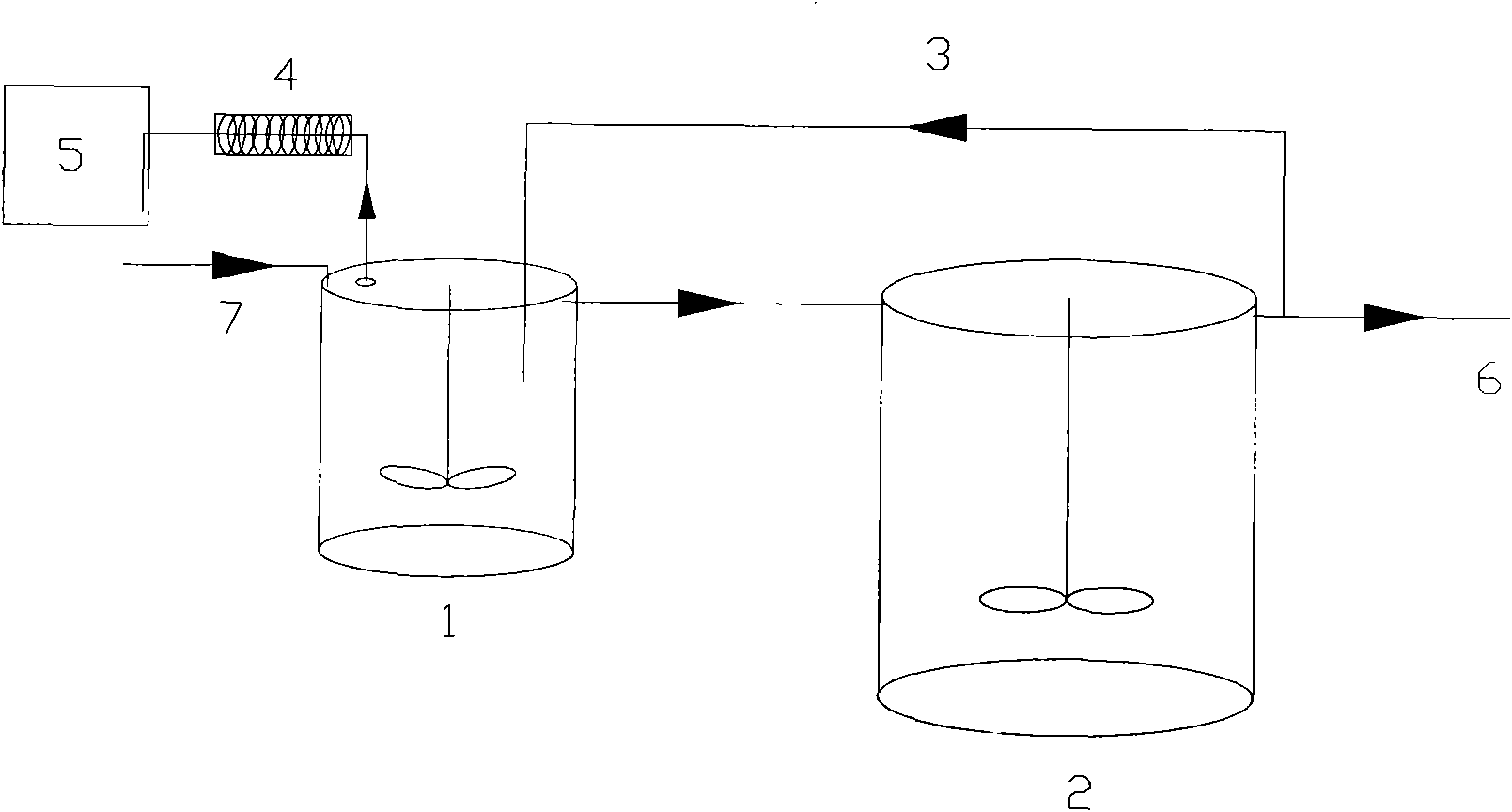

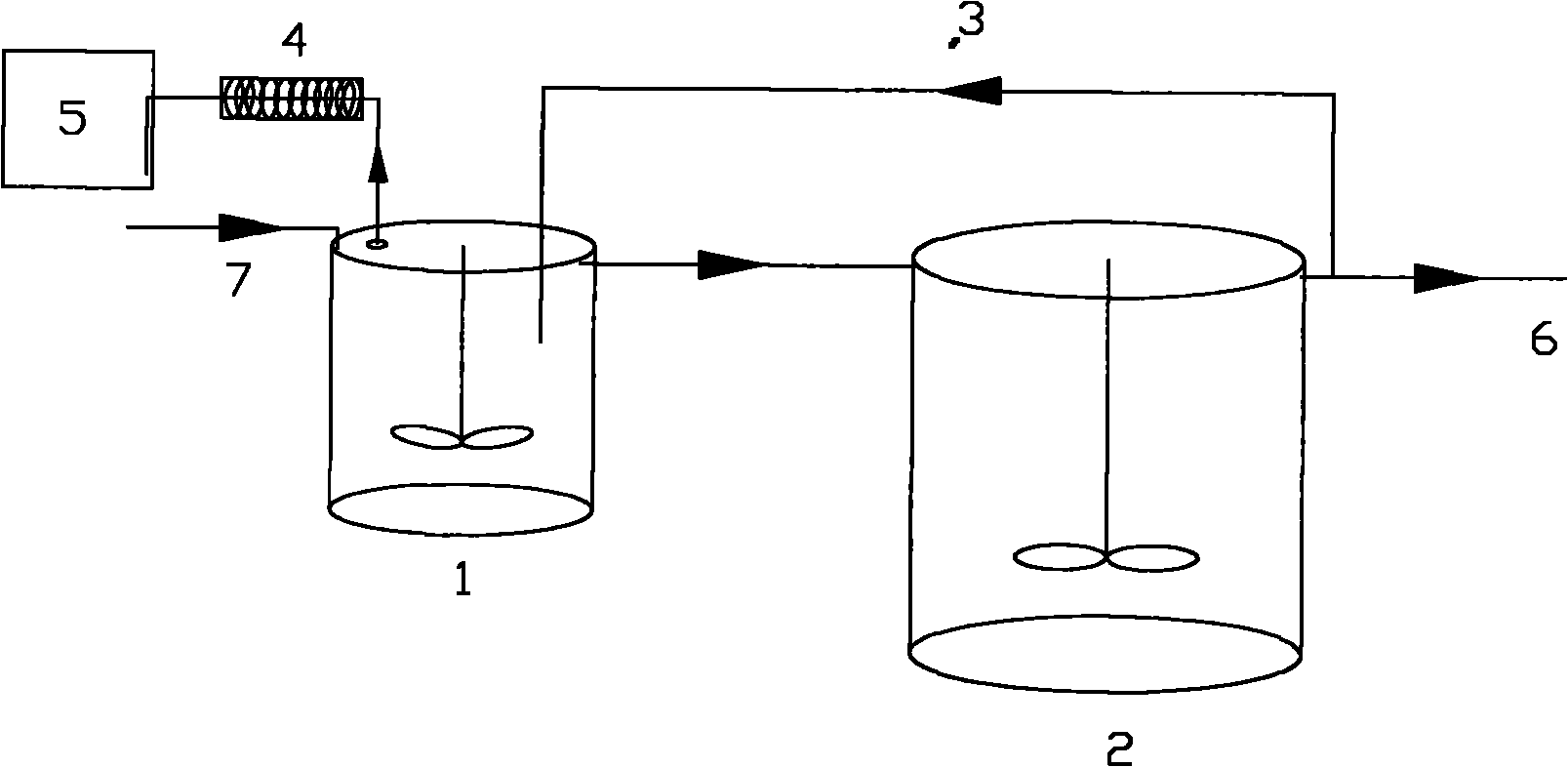

[0020] combine figure 1 The specific description of the embodiment of the present invention is as follows:

[0021] Cultivate ethanol-type fermentation bacteria with a simple liquid-phase carbon source as a substrate, add the cultivated ethanol-type fermentation bacteria into the fermentation reactor (2) as inoculation sludge, and control various parameters (pH value, alkalinity, temperature, Oxidation-reduction potential, etc.) Control the fermentation reactor (2) in the ethanol-type fermentation stage, and after the operation is stable, use the residual sludge product pretreated by the thermal hydrolysis reactor (1) to gradually replace the simple liquid phase substrate, and the ethanol-type fermentation The fermentation reactor (2) is controlled in the ethanol-type fermentation stage with sludge as the substrate. The remaining part of the product after fermentation is discharged through the sludge discharge pipe (6), and the other part is returned to the hot water through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com