Preparation method of maltooligosyltrehalose hydrolase gene sequence and recombinant protein thereof

A technology based on trehalose hydrolase and maltooligosaccharides, which is applied in the biological field and can solve problems such as unsatisfactory results and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Artificial modification and synthesis of maltooligosaccharide-based trehalose hydrolase (MTHase) gene

[0044] According to the above encoded amino acid sequence, forward and reverse strand DNA primers (as shown in SEQ ID NO: 6 to SEQ ID NO: 47) for gene splicing were designed according to the principle of yeast codon preference. Among them, an XhoI restriction site is added to the 5' end, and an EcoR I restriction site sequence is added to the 3' end to facilitate connection with the carrier.

[0045] Prepare primers with ultra-pure water so that the primer concentration is 100 pmol / μL, take 1 μL of primers respectively, mix and react in boiling water at 100 ° C for 15 minutes, and immediately put in ice bath; add 5 μL 10X T4 DNA ligase Buffer, T4 Polynucleotide Kinase 5 μL, add water to the total The volume is 45 μL, 37°C for 30 minutes; 65°C for 20 minutes, ice bath for 2 minutes; add 5 μL T4 DNALigase, react for 2 hours at 16°C, 65°C for 20 minutes.

[00...

Embodiment 2

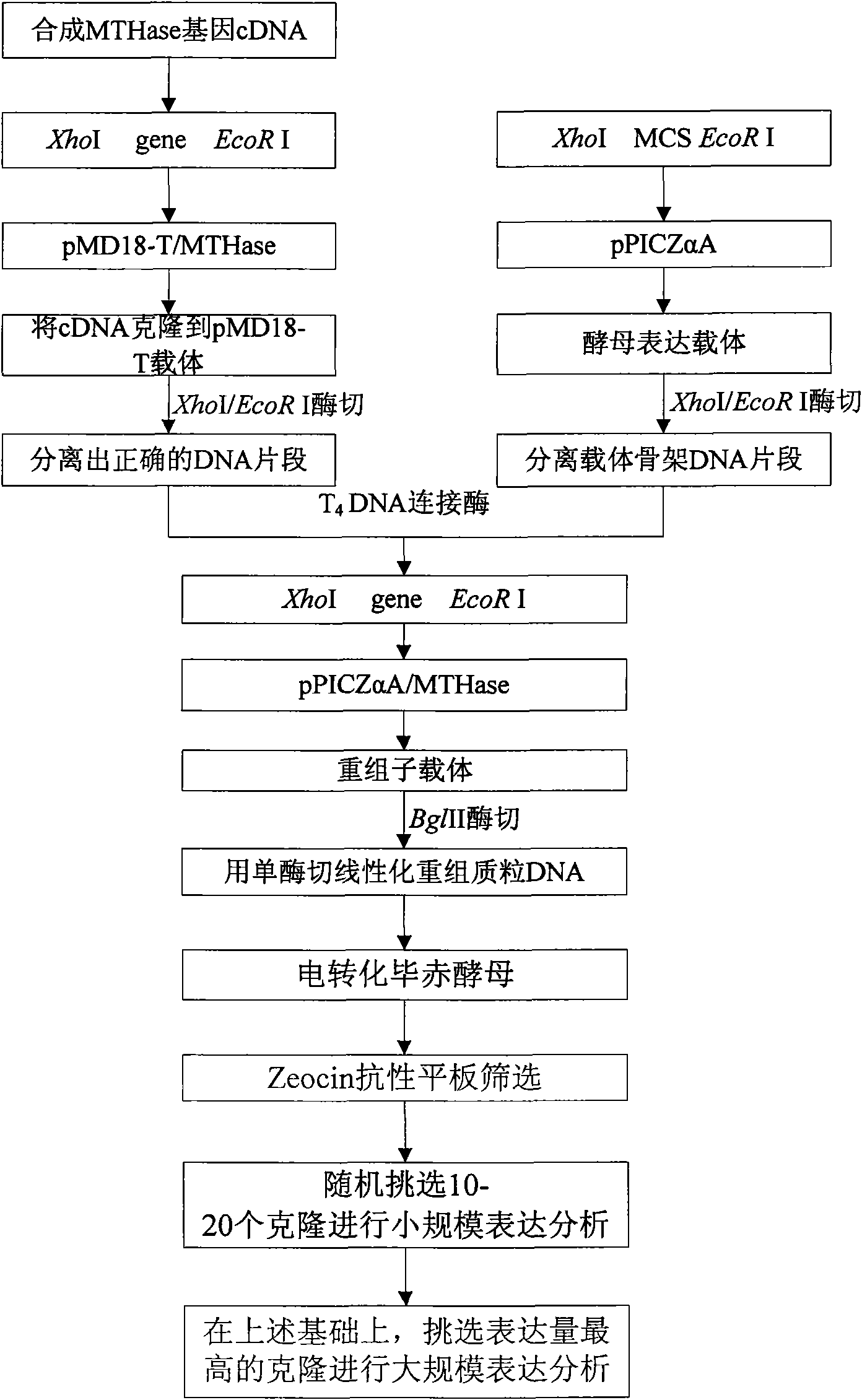

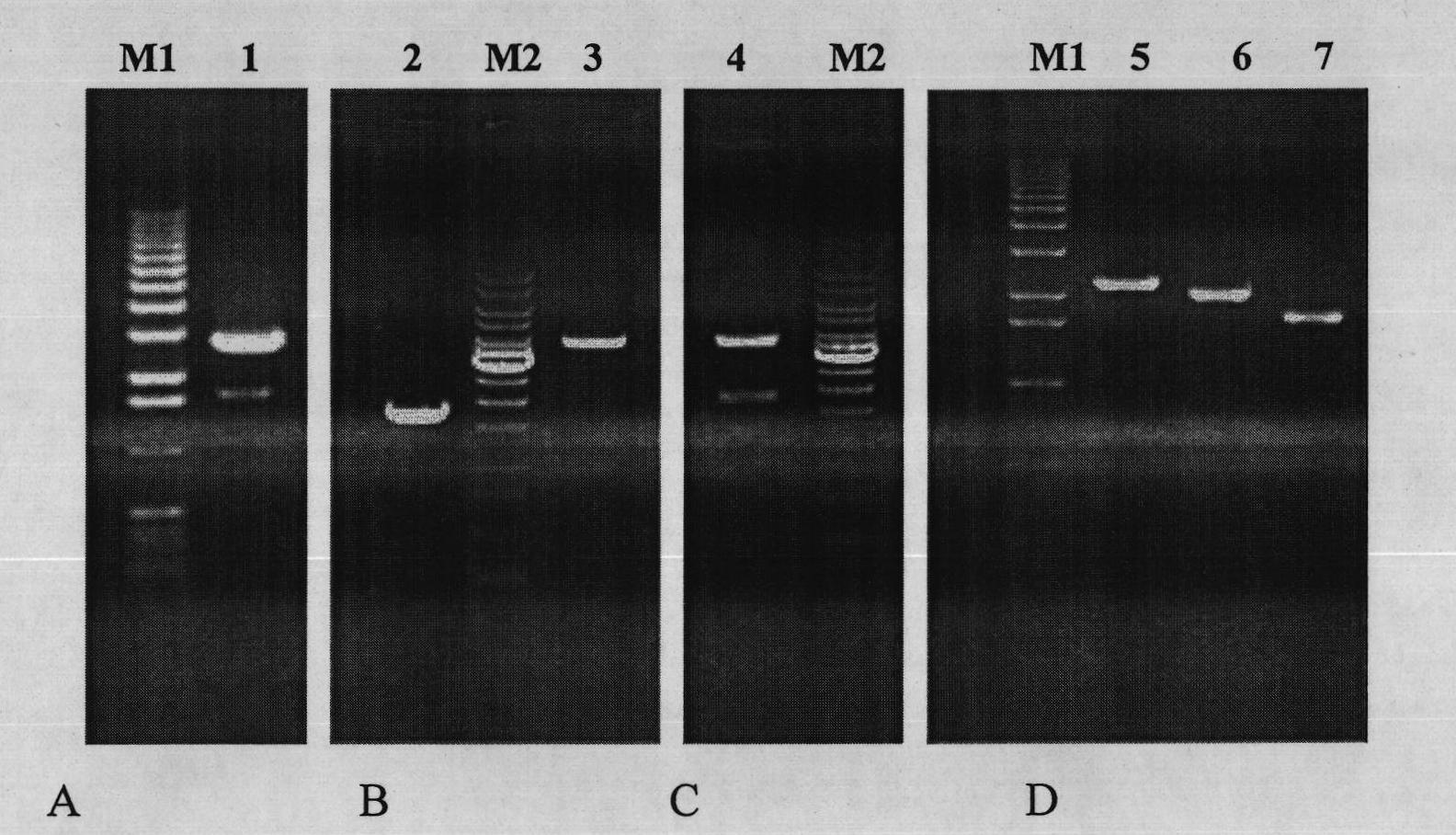

[0047] Example 2 Construction of recombinant expression plasmids and screening of positive clones

[0048] The PCR product finally obtained in Example 1 was purified and recovered, connected to pMD18-T vector (Takara, Dalian Bao Biological Engineering Company), after sequence analysis and selection of the correct positive clone pMD8-T / MTHase, the obtained sequence is SEQ ID NO : 4. Carry out double digestion with XhoI / EcoRI, isolate and recover the MTHase gene fragment of about 1.7kb, connect it to the pPICZαA yeast expression vector (Invitrogen, USA) through XhoI / EcoRI double digestion, and screen out positive clones pPICZαA / MTHase. After the positive cloning vector was digested with BglII, it was transformed into Pichia pastoris SMD1168H yeast, and the positive cloning strain was screened on high-concentration Zeocin-YPD solid medium ( Pichia pastoris SMD1168H / pPICZαA-MTHase ) and further confirmed by PCR.

Embodiment 3

[0049] Example 3 Culture medium and culture expression conditions

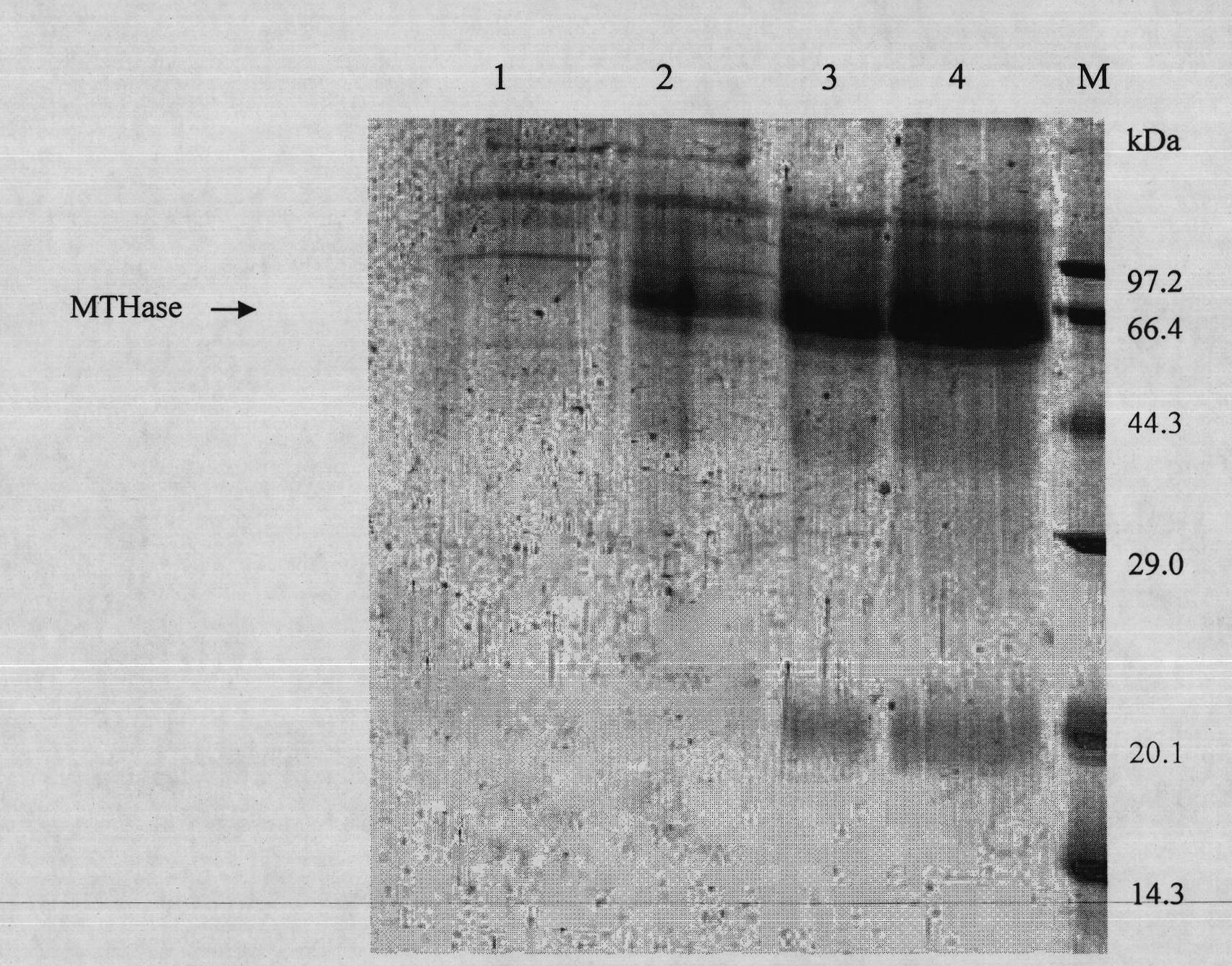

[0050] The positive bacterial strain described in embodiment 2 ( Pichia pastoris MD1168H / pPICZαA-MTHase ) was inoculated in YPD medium, cultured at 30°C for 12-24h, and the shaker speed was 240rpm; when the concentration of the fermentation broth reached OD 600 When = 5.0, transfer the inoculum to BMG culture medium according to the volume ratio of 1:100 for cultivation, the temperature is 30°C, the rotating speed of the shaker is 240rpm, cultivate for 28-35h; centrifuge at 5000g for 5min, collect the thalline, and wash the thalline with PBS 1-2 times, transfer to BMM liquid medium, and when the concentration of the fermentation broth reaches OD=0.5-1.0, induce culture, the induction temperature is 25°C, the shaker speed is 180rpm, and 5- 0.5% methanol at 10mL / L, cultured for 72 hours;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com