Method for preparing piezoelectric-ferroelectric thin film

A ferroelectric thin film and piezoelectric technology, applied in the field of piezoelectric ferroelectric thin film preparation, can solve the problems of high cost and slow deposition speed, and achieve strong applicability, highly preferred orientation grain size, and strong program controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

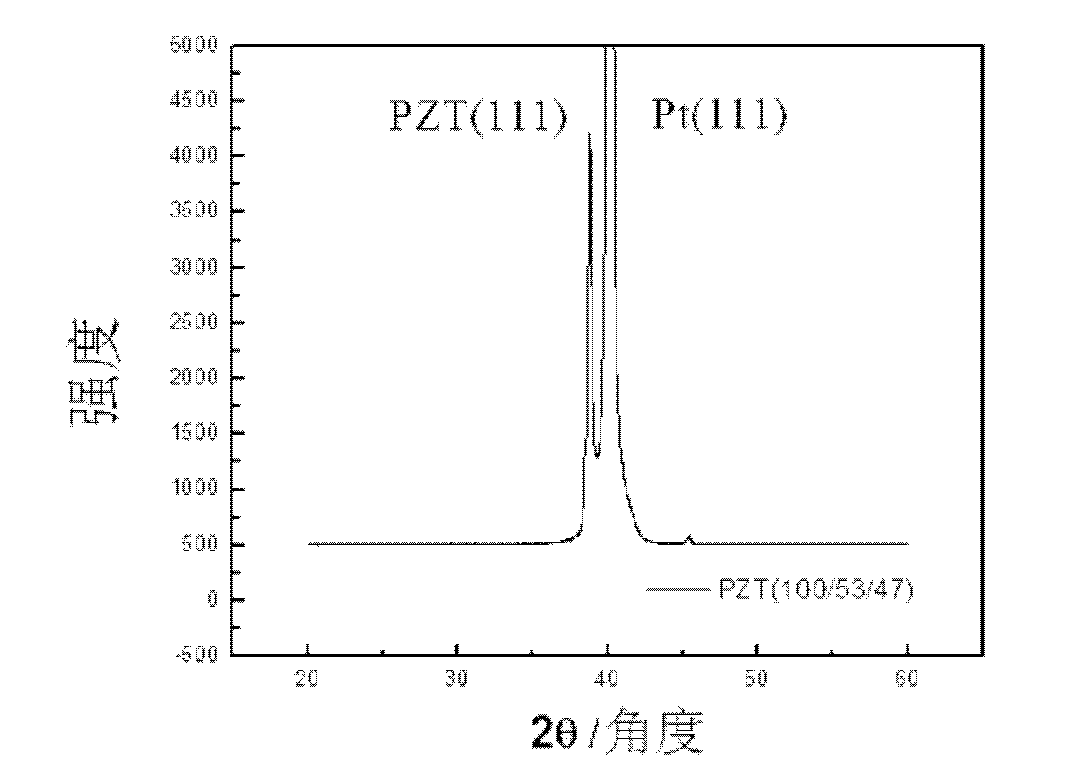

Embodiment 1

[0030] The first step is to prepare 80ml of PZT (PbZr 0.53 Ti 0.47 o 3 ) precursor solution: Weigh 17.449 grams (0.046mol) of lead acetate trihydrate crystals, add 50ml of ethylene glycol methyl ether, heat to make it completely dissolved, and then reflux at 120°C for one hour; take 6.475ml (0.019mol ) of pure tetrabutyl titanate, add 50ml ethylene glycol methyl ether and 6ml acetylacetone, and place it at 80°C for 20 minutes under the condition of ultrasonic vibration to make it evenly mixed; weigh 9.101 grams (0.021mol) of zirconium nitrate , was added to the above solution, and stirred uniformly for 5 minutes; the mixed solution was placed at 80°C and ultrasonically oscillated for 20 minutes to make it evenly mixed; the above two solutions were mixed; the mixed solution was placed at 80°C, ultrasonically Place it under shaking conditions for 30 minutes to make it evenly mixed; then use acetic acid to titrate to make the pH value 2.8; stir the above solution at 80°C, the s...

Embodiment 2

[0035] Prepare 80ml of PZT (PbZr 0.53 Ti 0.47 o 3 ) precursor solution: Weigh 24.429 grams (0.064mol) of lead acetate trihydrate crystals, add 50ml of ethylene glycol methyl ether, heat to make it completely dissolved, and then reflux at 120°C for one hour; take 9.066ml (0.026mol ) of pure tetrabutyl titanate, add 50ml of ethylene glycol methyl ether and 6ml of acetylacetone, and place it at 80°C for 20 minutes under the condition of ultrasonic vibration to make it evenly mixed; weigh 12.742 grams (0.030mol) of zirconium nitrate , added to the above solution, and stirred evenly for 5 minutes; the molar concentration ratio of metal ions in the precursor solution is Pb:Zr:Ti=1.15 / 0.53 / 0.47; the mixed solution was placed at 80°C and ultrasonically oscillated for 20 minutes , to make it evenly mixed; use CH 3 COOH titration, so that the pH value is 2.7; the stirring speed is 260 rpm, and the stirring time is 6 hours; the natural aging time is 60 hours; the rest are the same as ...

Embodiment 3

[0037] Prepare 80ml of PZT (PbZr 0.3 Ti 0.7 o 3 ) precursor solution: Weigh 17.449 grams (0.046mol) of lead acetate trihydrate crystals, add 50ml of ethylene glycol methyl ether, heat to make it completely dissolved, and then reflux at 120°C for one hour; take 9.644ml (0.028mol ) of pure tetrabutyl titanate, add 50ml of ethylene glycol methyl ether and 6ml of acetylacetone, and place it at 80°C for 20 minutes under the condition of ultrasonic vibration to make it evenly mixed; weigh 5.151 grams (0.012mol) of zirconium nitrate , added to the above solution, and stirred evenly for 5 minutes; the molar concentration ratio of metal ions in the precursor solution is Pb:Zr:Ti=1.15 / 0.3 / 0.7; the mixed solution was placed at 80°C and ultrasonically oscillated for 20 minutes , make it evenly mix; All the other are with embodiment one. 3 micron thick PbZr can be obtained 0.3 Ti 0.7 o 3 Ferroelectric thin film, wherein the seed layer prepared by PLD is about 0.5 micron. After measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com