Method for preparing commercial organic fertilizer from yam vinasse

A technology for commercial organic fertilizers and potatoes, which is applied in the treatment of biological organic parts, waste fuels, etc., can solve the problems of poor direct drying effect, difficult separation, wide area, etc. Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

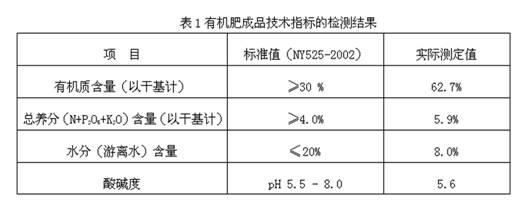

Examples

Embodiment 1

[0014] (1) Alcohol is produced from dried and crushed cassava. Pump the distiller's grain residue liquid into the biogas fermentation tank; ferment to produce biogas, biogas residue and biogas slurry, and the biogas is used to heat the boiler after desulfurization; biogas residue and biogas slurry are used for the production of organic fertilizers;

[0015] (2) Initial separation of biogas residue and biogas slurry: After the biogas residue and biogas slurry come out of the fermentation tank, they enter the settling tank. Most of the biogas residue with a specific gravity greater than water settles to the bottom, and the lower layer of sediment is collected into the sludge concentration tank. The upper layer of liquid Self-flow to the air flotation tank for air flotation treatment; the upper organic matter after air flotation treatment is also incorporated into the sludge thickening tank;

[0016] (3) Pressure filtration: use a mud pump to pump the sludge in the sludge thicken...

Embodiment 2

[0023] (1) The winery uses dried and crushed potatoes as raw materials to produce alcohol; the distiller's residue is pumped into the biogas digester for fermentation to produce biogas, biogas residue, and biogas slurry, and the biogas is used for heating boilers after desulfurization.

[0024] (2) Initial separation of biogas residue and biogas slurry: biogas residue and biogas slurry are pumped from the fermentation tank into the settling tank, most of the biogas residue with a specific gravity greater than water settles to the bottom, the lower layer of sediment is collected into the sludge concentration tank, and the upper layer of liquid flows by itself Go to the air flotation tank for air flotation treatment. The organic matter in the upper layer after air flotation treatment also enters the sludge thickening tank;

[0025] (3) Pressure filtration: Use a mud pump to pump the sludge in the sludge thickening tank into the frame plate filter press for pressure filtration an...

Embodiment 3

[0029] (1) The winery uses dried and crushed sweet potatoes as raw materials to produce alcohol. Pump the distiller's grain residue liquid into the biogas digester for fermentation to produce biogas, biogas residue, and biogas slurry. After desulfurization, the biogas is used for the boiler of the alcohol plant, and the biogas residue and biogas slurry are used for the production of organic fertilizers;

[0030] (2) Initial separation of biogas residue and biogas slurry: After the biogas residue and biogas slurry come out of the fermentation tank, they enter the settling tank. Most of the biogas residue with a specific gravity greater than water settles to the bottom, and the lower layer of sediment is collected into the sludge concentration tank. The upper layer of liquid Self-flow to the air flotation tank for air flotation treatment. The organic matter in the upper layer after air flotation treatment also enters the sludge thickening tank;

[0031] (3) Pressure filtration:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com