Heavy oil processing combined process capable of using deasphalted oil efficiently

A technology of deasphalted oil and combined process, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, and treatment of hydrocarbon oil, etc. It can solve the problems of increased yield of dry gas and coke, decreased yield of light oil, Low yield of high-grade road asphalt and other problems, to achieve the effect of reduced carbon residue and impurity content, high aromatic content, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

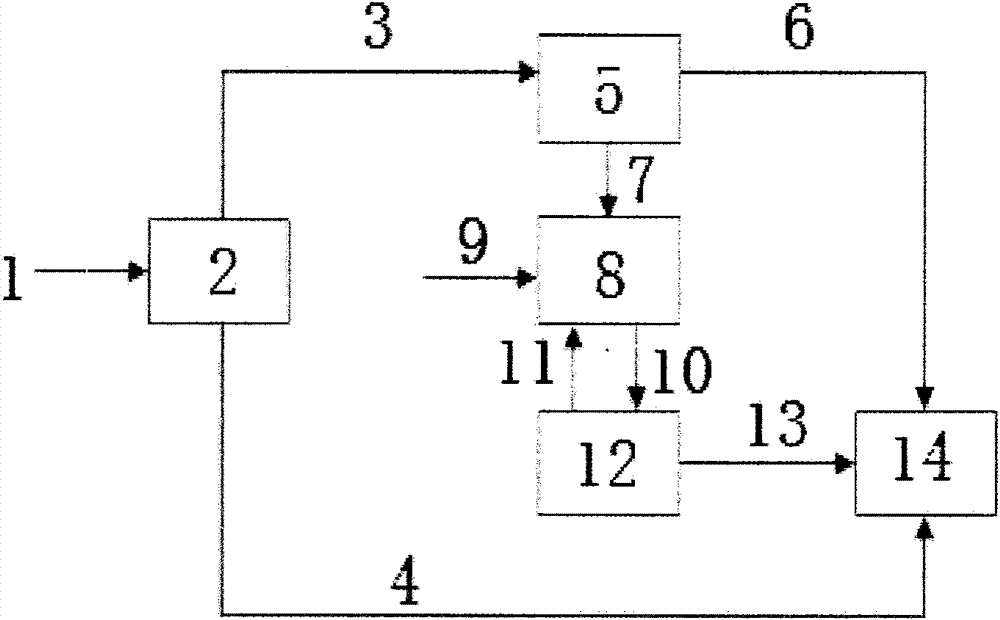

Method used

Image

Examples

Embodiment 1

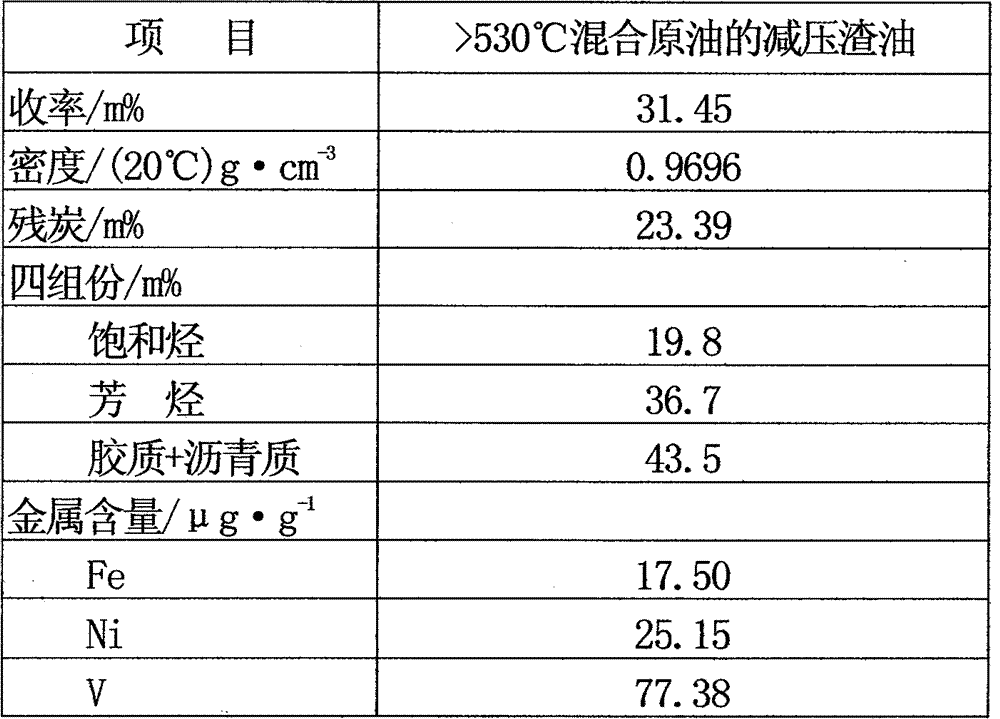

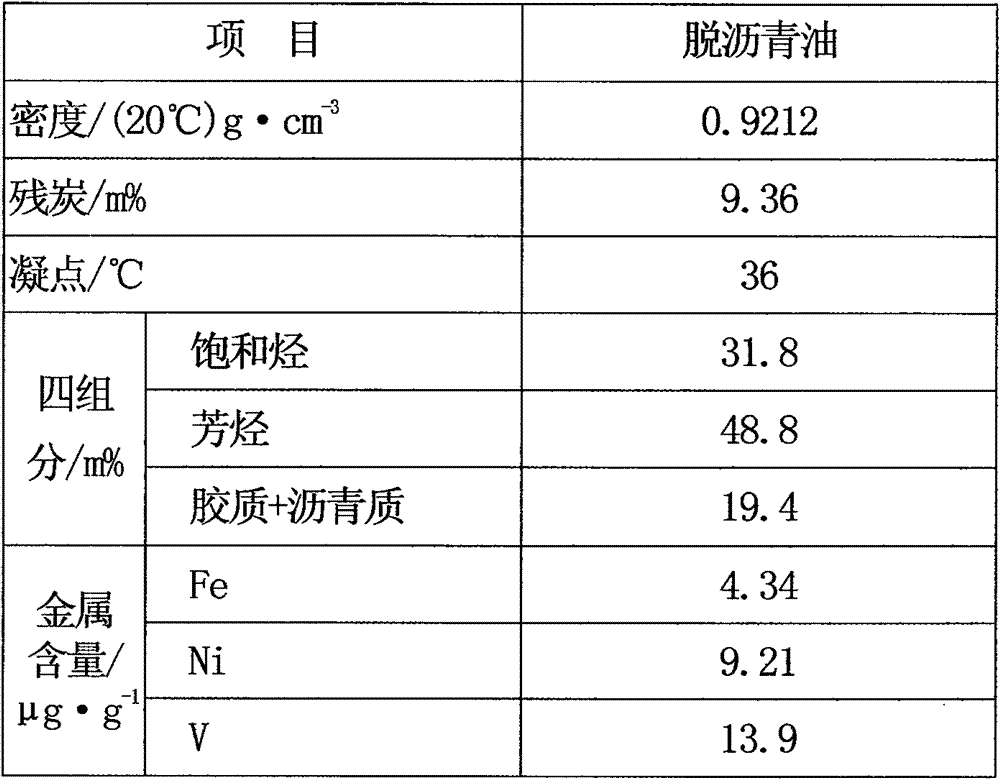

[0053] The properties of the vacuum residue of Zhongyuan, Tahe and Kaisajie mixed crude oil are as follows: figure 2 shown. Under the solvent deasphalting process conditions described in this embodiment, the properties of the obtained deasphalted oil 3 and deoiled hard asphalt 4 are shown in image 3 and Figure 4 . by image 3 The deasphalted oil 3 is used as the raw material of the deasphalted oil solvent extraction process 5, and the reverse contact with furfural in the extraction tower is carried out for liquid-liquid extraction, the extraction pressure is normal pressure (gauge pressure), and the extraction temperature is 70 °C , The agent-to-oil ratio (furfural / deasphalted oil) is 2.5:1 (by mass). Obtain extracted oil 6 and raffinate oil 7, its yield and properties are as Figure 5 and Figure 6 shown.

[0054] use Figure 5 The raffinate oil 7 in, the light oil slurry 11 in table 8, the vacuum gas oil and the atmospheric residue are mixed in the ratio of 24:3:5...

Embodiment 2

[0061] Under the solvent deasphalting process conditions described in this embodiment, the properties of the obtained deasphalted oil 3 and deoiled hard asphalt 4 are shown in Figure 12 and Figure 13 .

[0062] With deasphalted oil 3 in table 11 as the raw material of deasphalted oil solvent extraction process 5, carry out liquid-liquid extraction with furfural reverse contact in extraction tower, extraction pressure is 0.4Mpa (gauge pressure), extraction temperature The temperature is 80°C, and the agent-to-oil ratio (furfural / deasphalted oil) is 2.0:1 (mass). Obtain extracted oil 6 and raffinate oil 7, its yield and properties are as Figure 14 and Figure 15 shown.

[0063]With raffinate oil 7 in table 13, light oil slurry 11 in table 16, vacuum gas oil and atmospheric residue are mixed in the ratio of 23:2:56:19 (mass), as catalytic cracking process of the present invention The feed of 8; The deasphalted oil (as shown in table 2) of contrast test is directly used as...

Embodiment 3

[0070] Under the solvent deasphalting process conditions described in this embodiment, the properties of the obtained deasphalted oil 3 and deoiled hard asphalt 4 are shown in Figure 20 and Figure 21 .

[0071] The deasphalted oil 3 in Table 19 is used as the raw material of the deasphalted oil solvent extraction process 5, and N-methylpyrrolidone is reversely contacted in the extraction tower for liquid-liquid extraction, and the extraction pressure is 0.8MPa (gauge pressure) , the extraction temperature is 80°C, and the agent-oil ratio (N-methylpyrrolidone / deasphalted oil) is 2.0:1 (by mass). Obtain extracted oil 6 and raffinate oil 7, its yield and properties are as Figure 22 and Figure 23 shown.

[0072] With raffinate oil 7 in table 21, light oil slurry 11 in table 24, vacuum gas oil and atmospheric residue are mixed in the ratio of 20:4:50:26 (mass), as catalytic cracking process of the present invention The feed of 8; the deasphalted oil (such as figure 2 sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com