Method and system for producing heterotrophic alga in high density

A density, seaweed technology, applied in the field of high-density growth of heterotrophic microalgae and production of omega-3 fatty acids, can solve problems such as by-product applications that are not discussed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

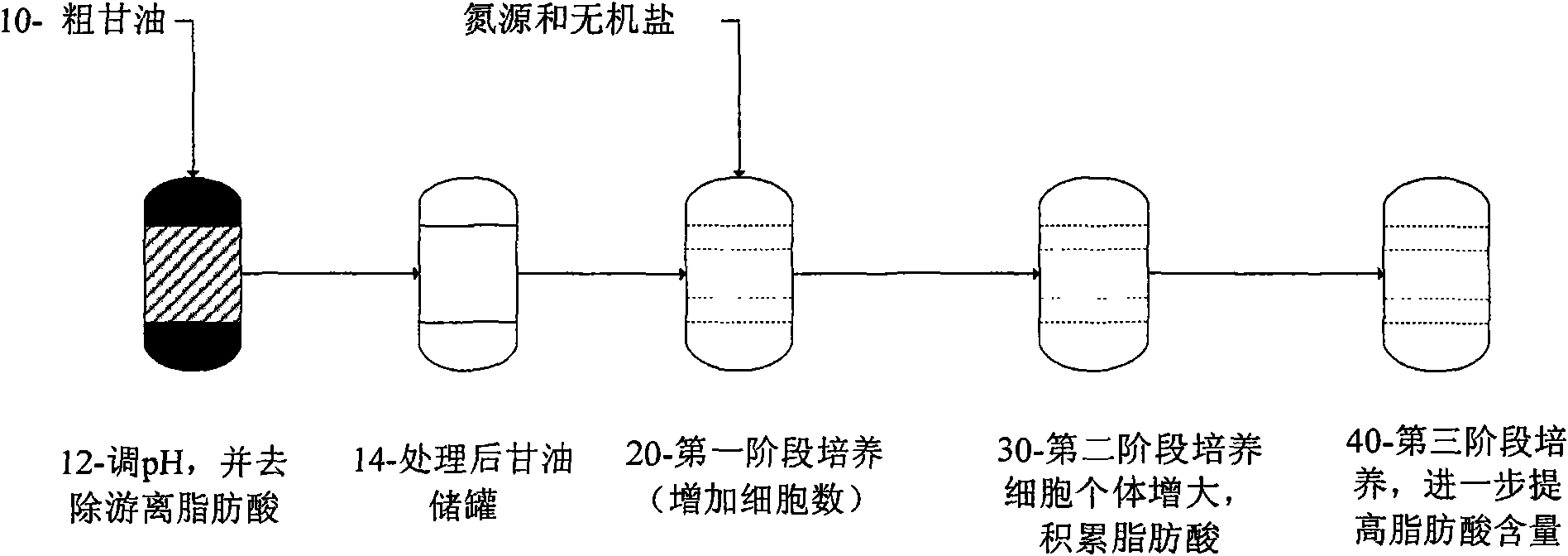

[0044] Implementation example 1. The regulation and control of the first stage reaction parameter

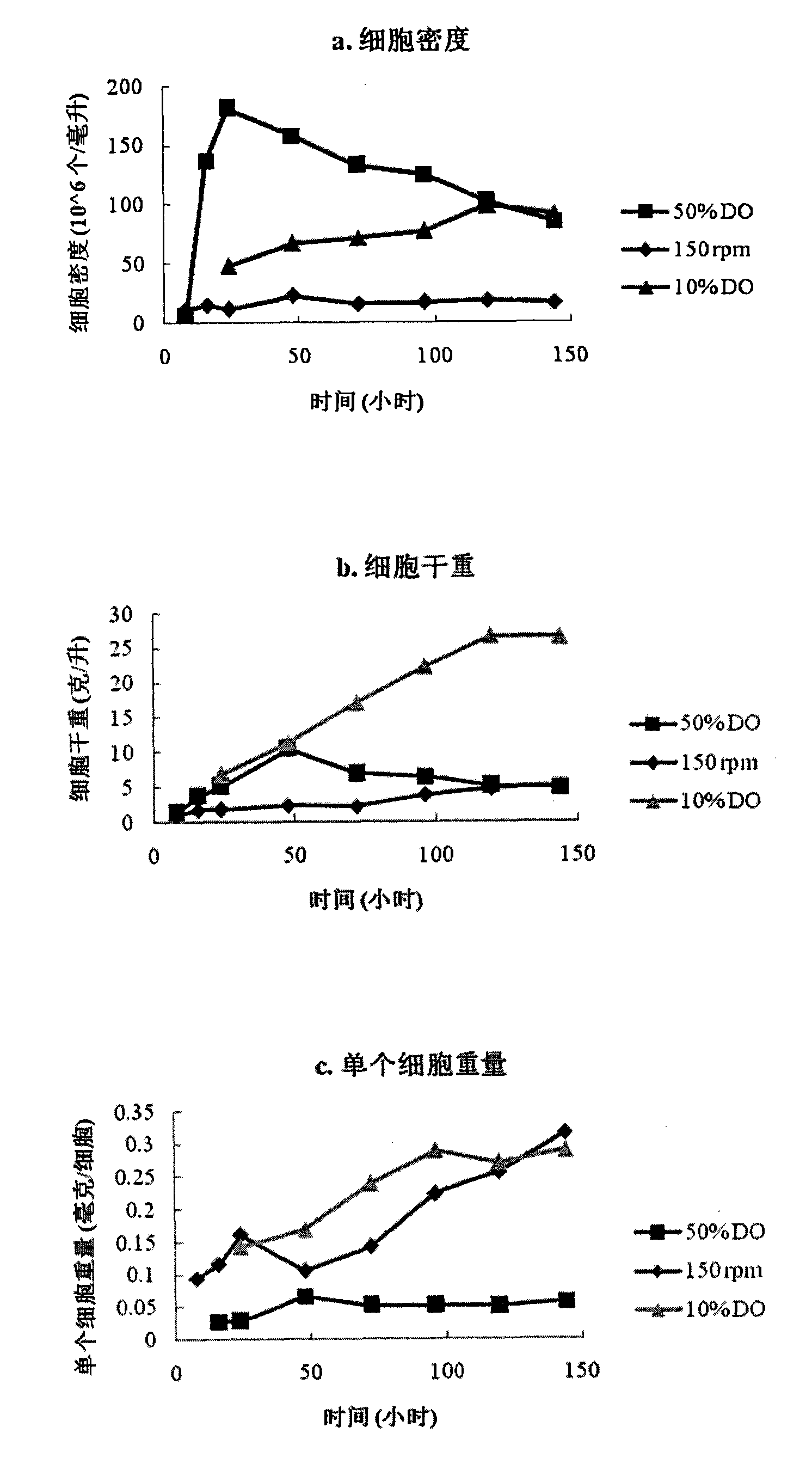

[0045] The effective control of the first-stage reaction parameters described in the present invention establishes fermentation conditions that convert limited cell resources into cell growth and exponential increase in cell number. See figure 2 and Table 2.

[0046] figure 2 It was shown that dissolved oxygen (DO) plays a major role in process control (in coordination with temperature and carbon / nitrogen source changes). As can be seen, as dissolved oxygen rises, cellular energy is diverted to the synthesis of chemicals necessary for cell division, thus significantly increasing cell number with little effect on cell size. Conversely, reducing dissolved oxygen will allow cellular energy to focus on cell growth and lipid accumulation.

[0047] The process control gave 181 × 10 after 24 hours at 50% DO 6 cells / ml, but decreased to 22.5×10 at 48 hours 6 cells / ml. The cell ...

Embodiment 2

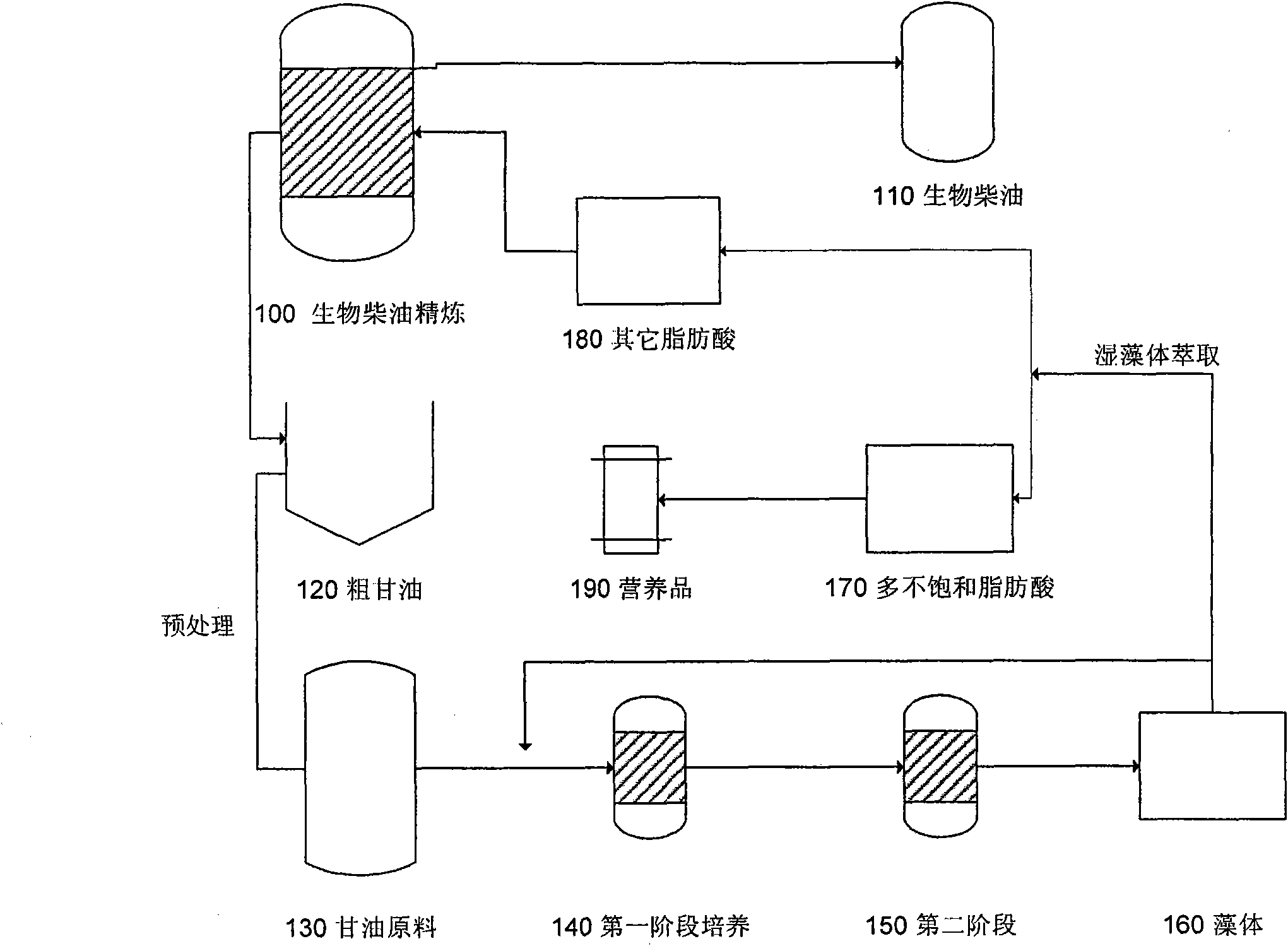

[0055] The initial medium consisted of 40 g / L glycerol, 5 g / L yeast extract, 5 g / L ammonium acetate as nitrogen source and other insignificant factors in seawater. Cells from the smaller flasks were inoculated into fermentors at a 10% (v / v) inoculum size. The temperature is controlled at 30°C, and the dissolved oxygen is controlled at 20%-50%. The first stage, also called the cell number increase stage, lasts for 24 hours. During this period, the cell number increases rapidly, and the final cell density is 400-800×10 6 cells / ml, and the higher the better. When the number of cells stops increasing, the second phase begins, where fatty acids begin to accumulate. At this stage, DO is controlled at 3-5%, and the concentration of glycerol and nitrogen source is controlled at 30-50g / L and 0.5-1.0g / L respectively by feeding. The temperature was still at 30°C, and this phase lasted until the 60th-80th hour of the whole process, until the dry weight of the cells stopped increasing. ...

Embodiment 3

[0075] Implementation example 3. Energy consumption comparison

[0076] Matlab-Simulink software can compare the energy consumption of the system. Simulate seaweed fermentation in a 5-ton fermenter, and use the data of 5L and 30L experiments as the basis for evaluation.

[0077] The basic parameters set for this process are: a fermenter with an effective volume of 5 cubic meters; a fed-batch fermentation scheme; a reaction temperature of 30°C; an average room temperature of 25°C; an aeration rate of 0.5vvm and 1.0vvm, and an electricity cost of $0.046 / kwh . The basic setting parameters of the heating system are: heat loss equivalent, q is the heat loss, h is the thermal conductivity of steel, A is the internal area, Ti the real internal temperature, T is the external temperature; the required heat is equivalent, Q is The amount of heat required, M is the total mass of the solution, Cp is the heat capacity, T is the target internal temperature, and Ti is the true internal tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com