Method for separating and purifying oligo-xylose by using simulated moving bed

A technology for simulating moving bed and xylo-oligosaccharide is applied in the field of separating and purifying xylo-oligosaccharide by using a simulated moving bed, which can solve the problems of difficult to effectively control the process, uneconomical separation process, influence on industrialized production, etc. The effect of realizing continuous operation and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

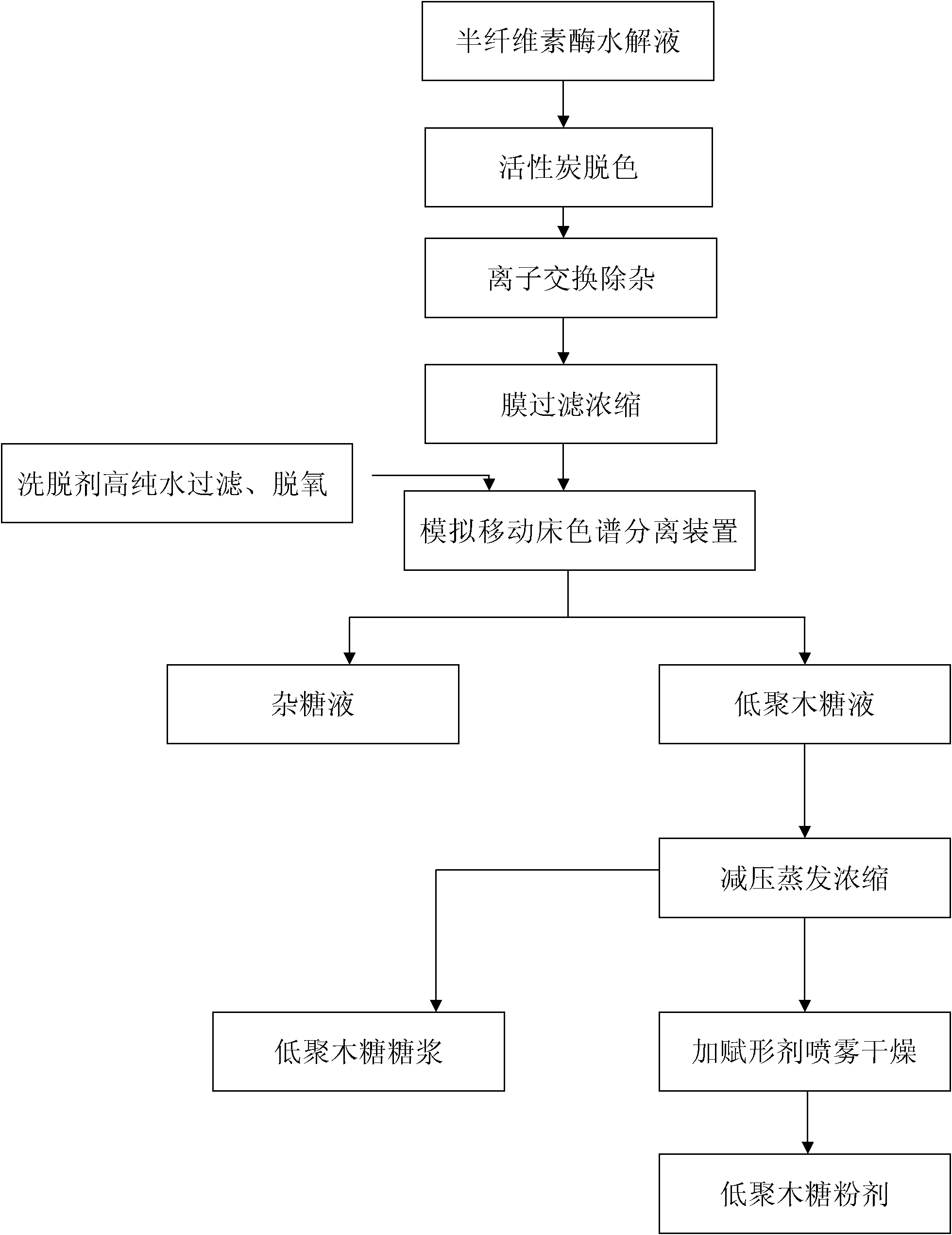

[0029] A method utilizing a simulated moving bed to separate and purify xylo-oligosaccharides, the steps are as follows:

[0030] (1) The feed liquid obtained by enzymatic hydrolysis of hemicellulose is pretreated by activated carbon decolorization, ion exchange to remove impurities, membrane filtration and concentration, and the solid content is 54.25%; the content of each component is detected by high performance liquid chromatography. The content of xylo-oligosaccharides is 68.4%, and the content of miscellaneous sugars such as xylose and arabinose is 31.5%. High-purity water is filtered and deoxygenated for later use.

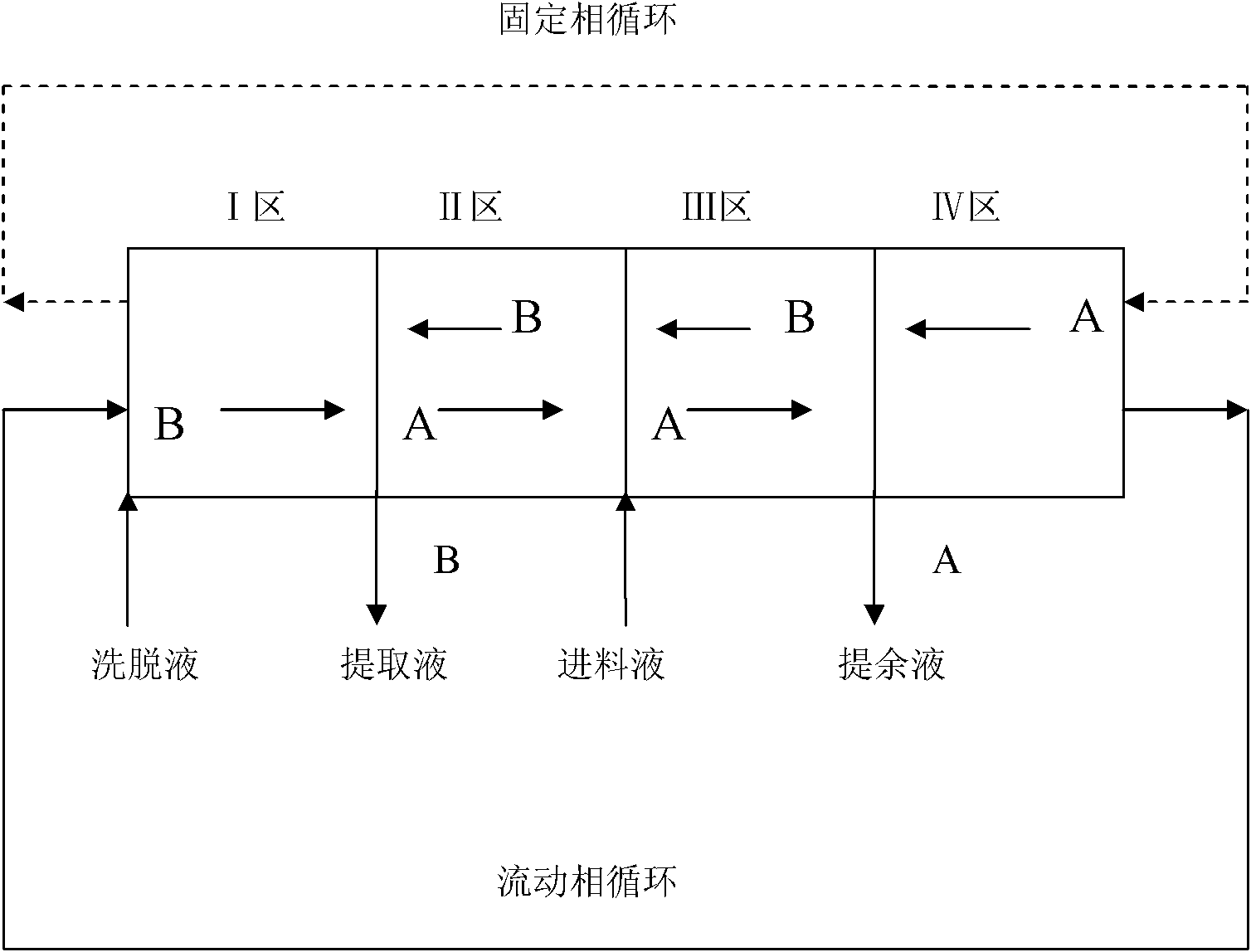

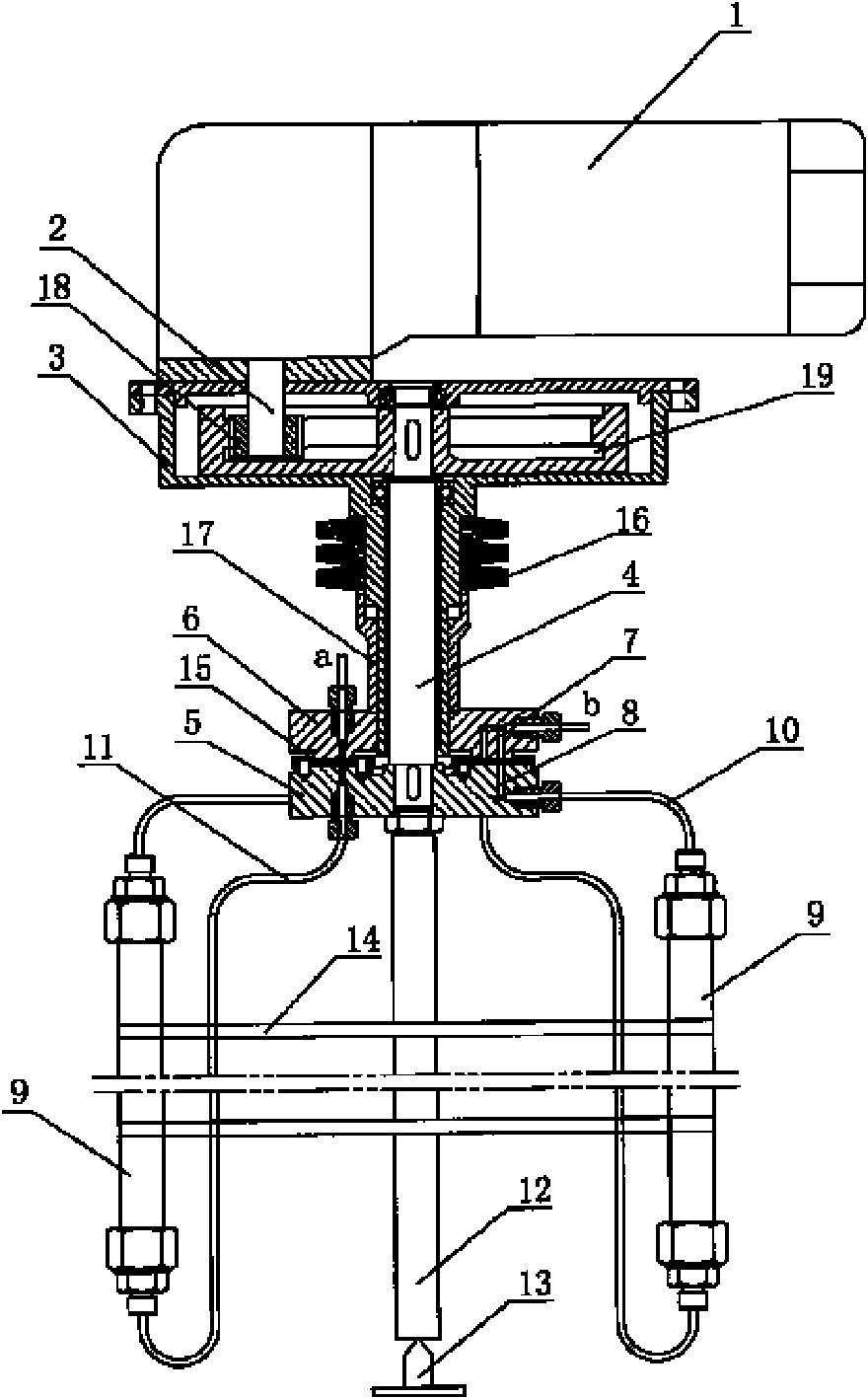

[0031] (2) Start the switch of the column thermostat and the water bath box to raise it to the set temperature of 70°C, and enter the pretreated raw material liquid into the simulated moving bed chromatographic separation device for separation. The process conditions are as follows: maintain the pressure ≤ 0.4Mpa, separate The temperature is 70°C, the flow ...

Embodiment 2

[0034] A method utilizing a simulated moving bed to separate and purify xylo-oligosaccharides, the steps are as follows:

[0035] (1) The feed liquid obtained by enzymatic hydrolysis of hemicellulose is pretreated by activated carbon decolorization, ion exchange to remove impurities, membrane filtration and concentration, and the measured solid content is 43.75%; the content of each component is detected by high performance liquid chromatography. The content of xylo-oligosaccharides is 72.3%, and the content of miscellaneous sugars such as xylose and arabinose is 26.7%. High-purity water is filtered and deoxygenated for later use.

[0036] (2) Start the switch of the column thermostat and the water bath box to raise it to the set temperature of 75°C, and enter the pretreated raw material liquid into the simulated moving bed chromatographic separation device for separation. The process conditions are as follows: maintain the pressure ≤ 0.5Mpa, separate The temperature is 75°C, ...

Embodiment 3

[0039] A method utilizing a simulated moving bed to separate and purify xylo-oligosaccharides, the steps are as follows:

[0040] (1) The feed liquid obtained by enzymatic hydrolysis of hemicellulose is pretreated by activated carbon decolorization, ion exchange to remove impurities, membrane filtration and concentration, and the measured solid content is 31.5%; the content of each component is detected by high performance liquid chromatography. The content of xylo-oligosaccharides is 70.36%, and the content of miscellaneous sugars such as xylose and arabinose is 29.1%. High-purity water is filtered and deoxygenated for later use.

[0041](2) Start the switch of the column thermostat and the water bath box to raise it to the set temperature of 70°C, and enter the pretreated raw material liquid into the simulated moving bed chromatographic separation device for separation. The process conditions are as follows: maintain the pressure ≤ 0.4Mpa, separate The temperature is 70°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com