Method for preparing cefuroxime sodium

A technology of cefuroxime sodium and cefuroxime acid, which is applied in the field of drug synthesis, can solve problems such as visible foreign matter and difficulty in aseptic control, prolonged post-processing steps, and increased product exposure opportunities, so as to reduce material powder exposure and human contact opportunity, short dissolution time, and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of cefuroxime sodium

[0021] Add 200ml of acetone and 30ml of purified water into a 500ml three-necked bottle, add 40g of cefuroxime acid, stir at a temperature of 25°C until it is completely dissolved, add 4g of activated carbon, filter with suction, and add completely dissolved cefuroxime to the filtrate at a temperature of 25~-30°C The mixed solution of sodium isooctanoate, sodium acetate and sodium lactate was stirred for 15 minutes after the addition, and 600ml of acetone was added dropwise to crystallize, stirred at a slow speed for 30 minutes to grow the crystals, suction filtered, washed with acetone, and dried for 2 hours to obtain the finished product of cefuroxime sodium. The content is 94.8%, and the maximum impurity is 0.2%.

Embodiment 2

[0022] Embodiment 2: the detection of cefuroxime sodium product property

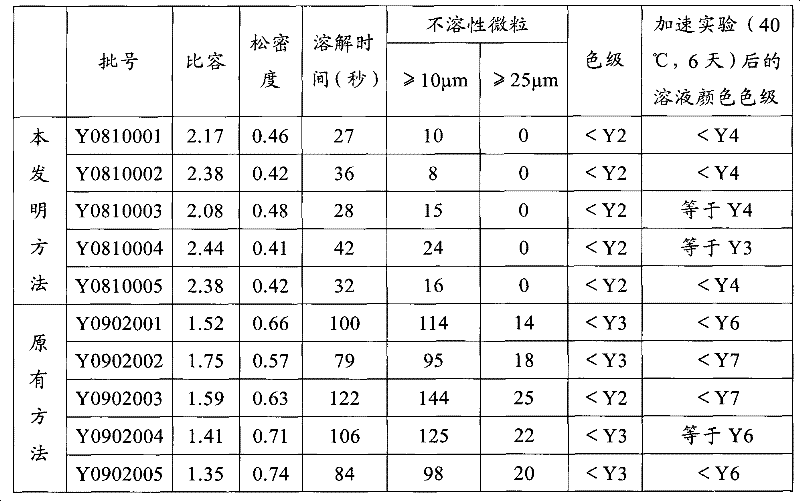

[0023] Prepare 5 batches of cefuroxime sodium products according to the preparation method in Example 1, the batch numbers are respectively Y0810001, Y0810002, Y0810003, Y0810004 and Y0810005, and these 5 batches of cefuroxime sodium products have been tested for the following items, and the results are shown in Table 1

[0024] Table 1 Test results of product properties of cefuroxime sodium

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com