Online analyzing method and device for product of ethylene reaction by biological ethanol dehydration

A bio-ethanol and reaction product technology, applied in measurement devices, analytical materials, material separation, etc., can solve the problems of long analysis time, high labor intensity, cumbersome and other problems, and achieve long analysis time, fast analysis speed, and high labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

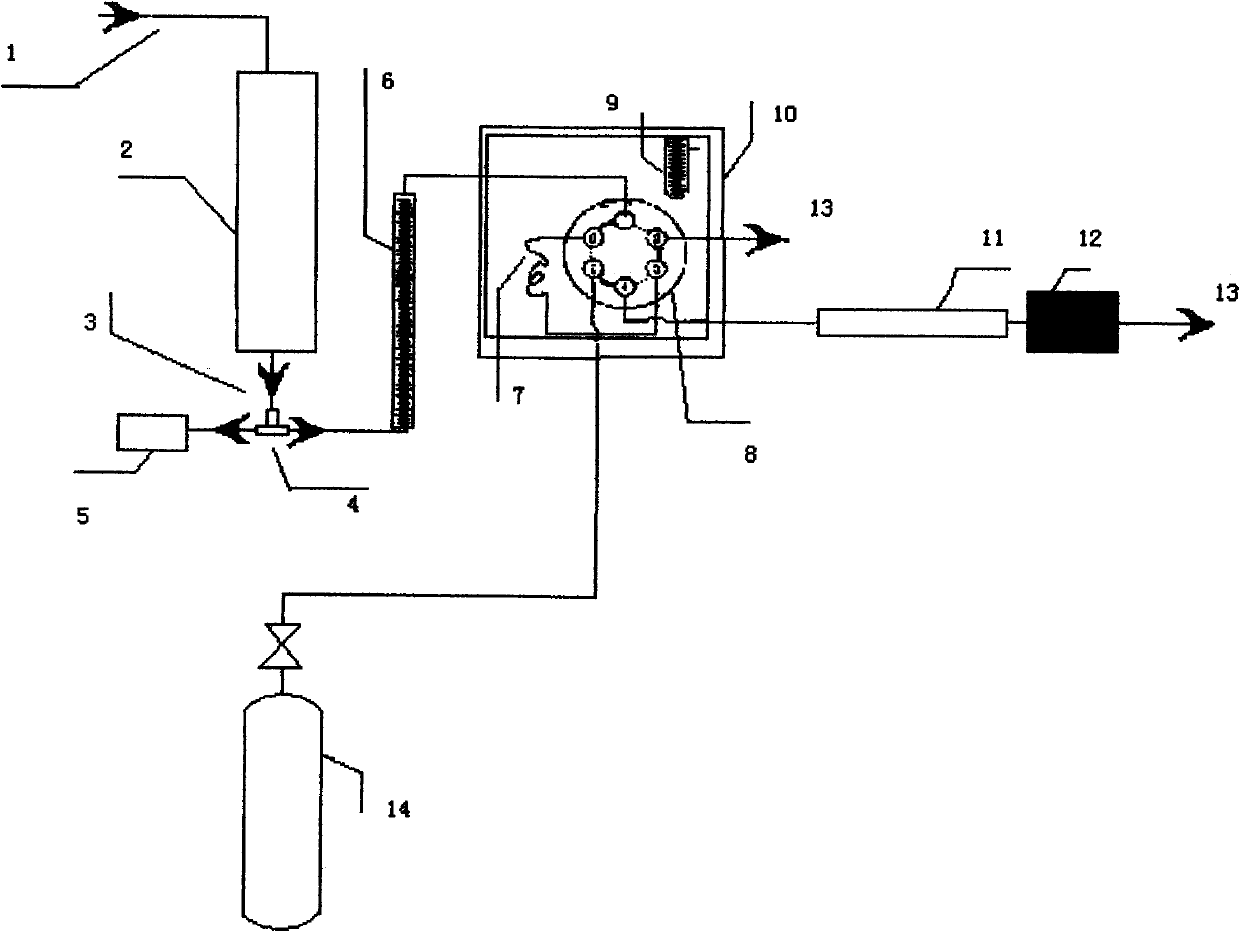

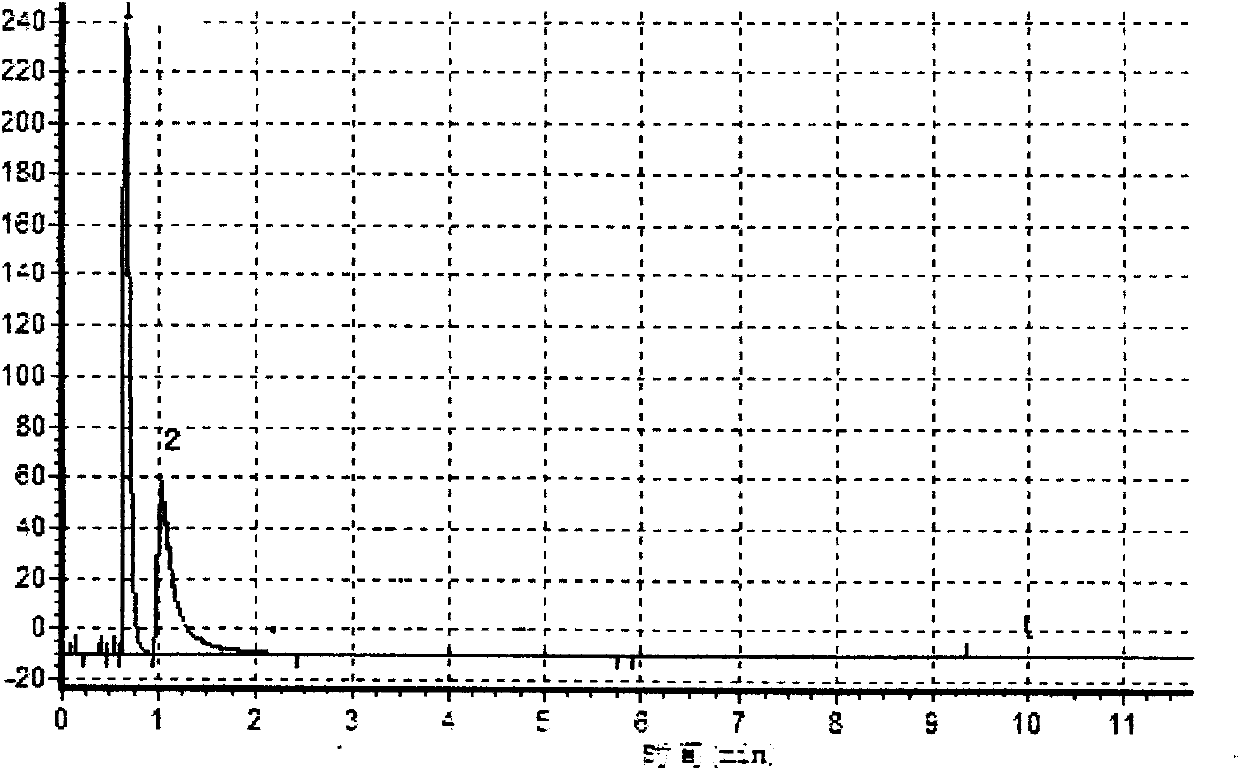

[0031] This example is the initial stage of the reaction, and there are more by-products at this time, refer to the attached figure 1 , the gas chromatograph used is SP-6890 gas chromatograph, and the delivery sample system between the reaction tower 2 and the six-way sampling valve 8 is installed with a three-way 4 and a gas path heating belt 6, and the six-way sampling valve 8 is placed in an insulated In the device 10 , the chromatographic column 11 is a stainless steel chromatographic column (2m×ф4mm, filled with GDX104 stationary phase), and the detector is a thermal conductivity cell detector 12 . The material is input by the infusion pump from the feed part 1 from the top of the reaction tower 2, and the gaseous product generated flows out from the bottom of the tower 3, and a tee 4 is installed on the gas path flowing to the ethylene product collector, and most of it enters the product collection system 5; at the same time A small part enters the chromatographic analys...

Embodiment 2

[0038] This example is product monitoring analysis, and this moment by product is less, mainly is product quality control analysis, and chromatographic operating condition is the same as embodiment 1, and what changed is only following condition:

[0039] Column head pressure: 0.4MPa, column temperature 110°C, vaporization temperature 150°C, TCD detector temperature 250°C, carrier gas is high purity

[0040] Nitrogen gas with a nitrogen flow rate of 60mL / min and a detector bridge current of 100mA.

[0041] Split injector, split ratio: 50:1

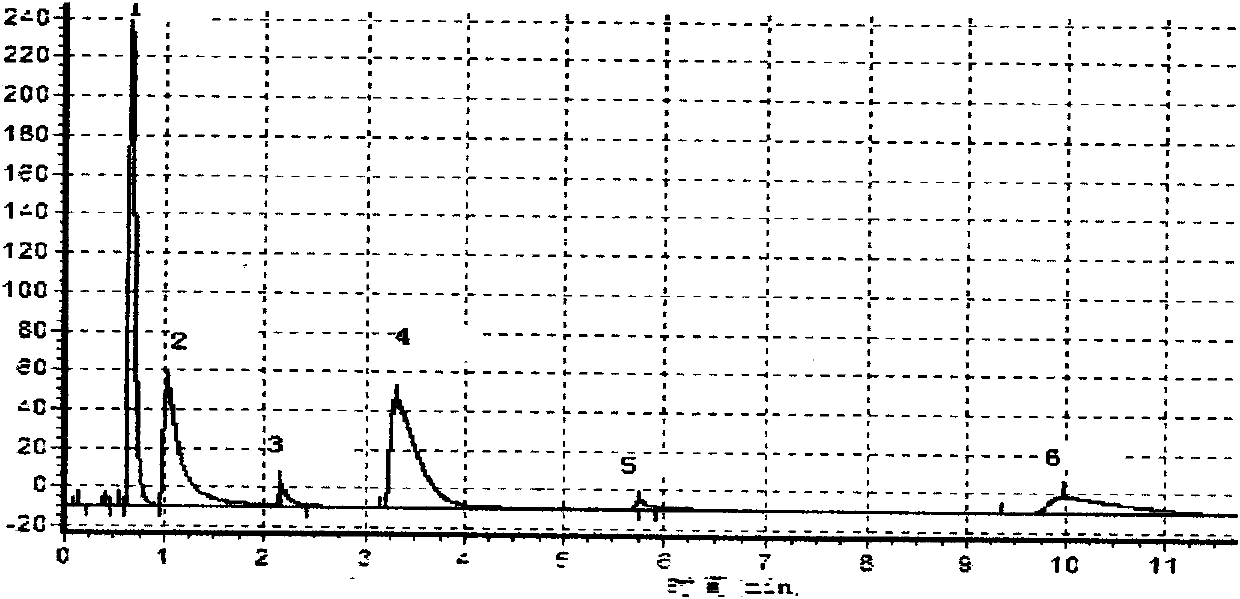

[0042] Separation chromatogram see figure 2 .

[0043] by chromatography figure 2 and chromatography image 3 It can be seen that under the chromatographic conditions of the present invention, each component is well separated and the peak shape is symmetrical, which is completely suitable for gas chromatography on-line analysis of bioethanol catalytic dehydration to ethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com