Method for preparing lithium iron phosphate nano material

A technology of lithium iron phosphate and nanomaterials, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve difficult problems such as increasing solid content, achieve significant modification effect, good processing performance and electrochemical performance, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select ferric phosphate, lithium hydroxide and magnesium acetate as raw materials, weigh them in a molar ratio of 1:1.02:0.01 and place them in an aqueous solution, add 20wt% glucose, the solid content reaches 50%, and the concentration is 1% of the mass of the precursor TH-904, mixed uniformly in a high-energy ball mill, spray-dried, and placed in an argon atmosphere furnace for heat treatment at 350°C for 2 hours, then heat-treated at 700°C for 20 hours and then cooled to room temperature to obtain the desired lithium iron phosphate material. Among them, TH-904 is a water dispersant produced by Shandong Taihe Water Treatment Co., Ltd.

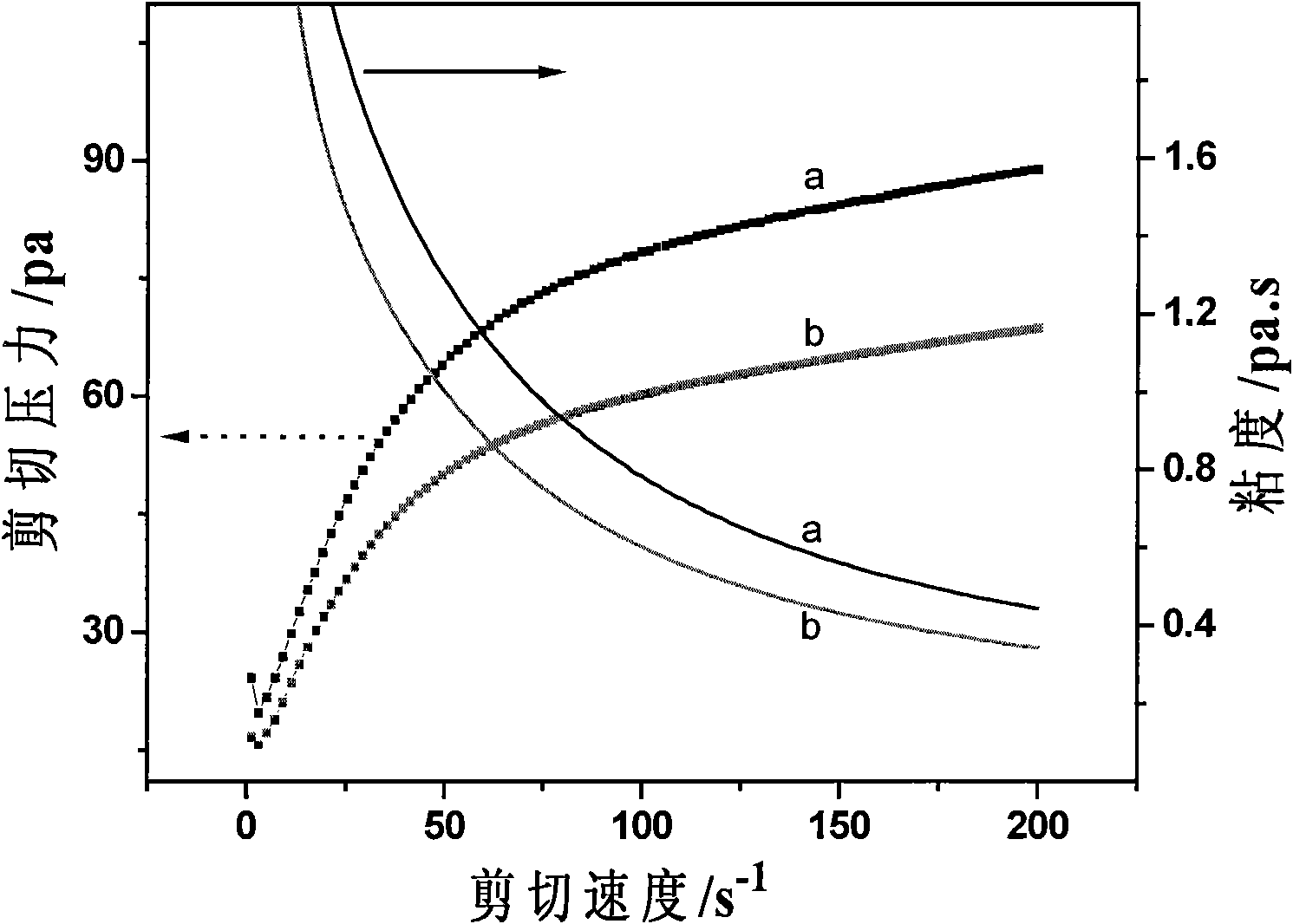

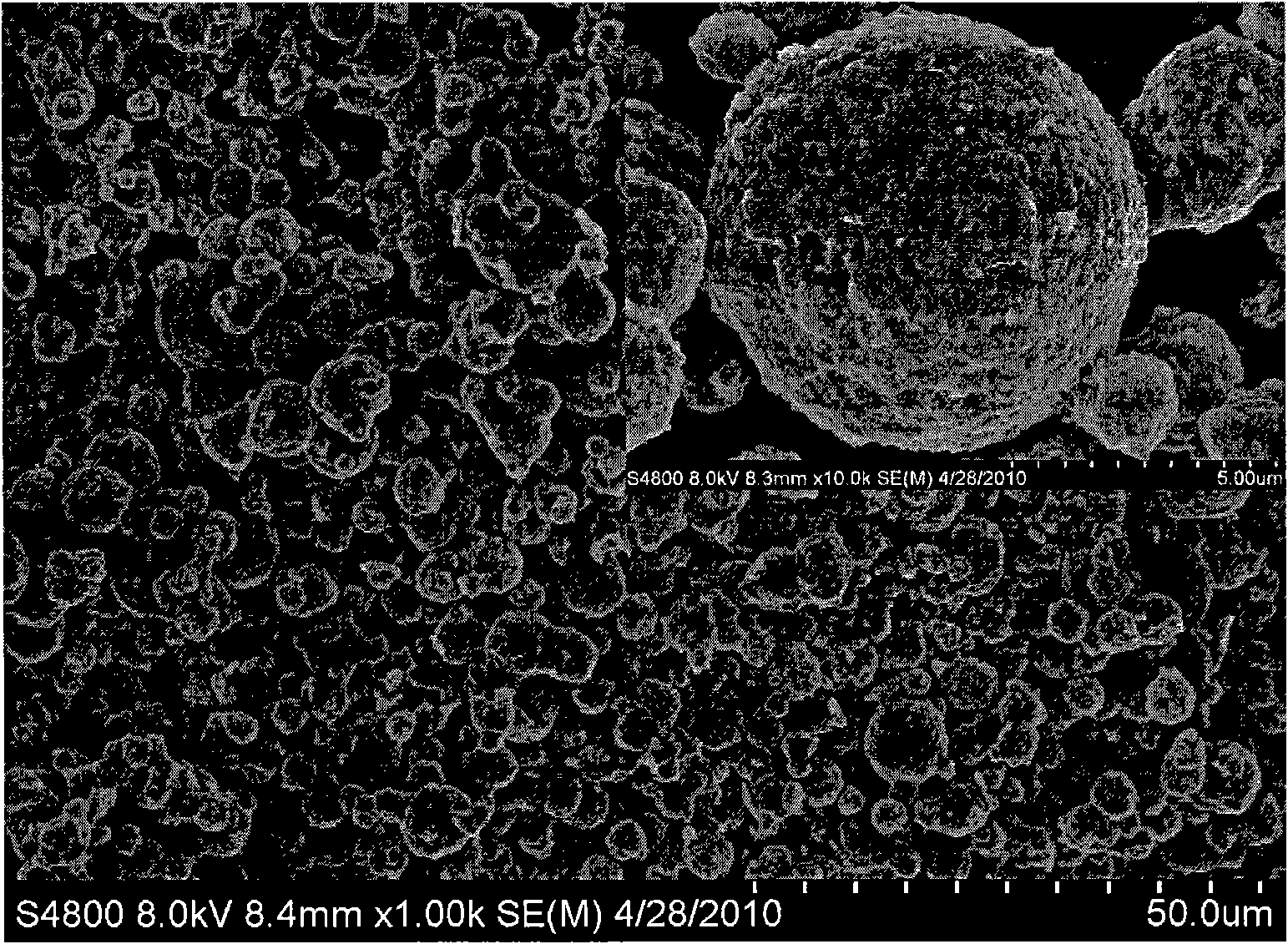

[0028] The obtained lithium iron phosphate material has a capacity of 150mAh / g and a tap density of 1.2g / ml. The viscosity-shear force relationship is as follows figure 1 As shown in b, its SEM image is shown in figure 2 shown.

Embodiment 2

[0030] Select ferric phosphate, lithium hydroxide and magnesium acetate as raw materials, weigh them in a molar ratio of 1:1.02:0.01 and place them in an aqueous solution, add 20wt% glucose, the solid content reaches 50%, and add 20% of the mass of the precursor TH- 904, mixed uniformly in a high-energy ball mill, spray-dried, and placed in an argon atmosphere furnace for heat treatment at 350°C for 2h, then heat-treated at 700°C for 20h and cooled to room temperature to obtain the desired lithium iron phosphate material.

[0031] The obtained lithium iron phosphate material has a capacity of 155mAh / g and a tap density of 1.3g / ml.

Embodiment 3

[0033] Select iron phosphate, lithium hydroxide and chromium oxide as raw materials, weigh them according to the molar ratio of 1:1.02:0.01, and place them in absolute ethanol solution, add 20wt% glucose, the solid content reaches 50%, and add 0.01% of the mass of the precursor TH-908, mixed uniformly in a high-energy ball mill, spray-dried, and placed in an argon atmosphere furnace for heat treatment at 350°C for 2h, then heat-treated at 700°C for 20h and cooled to room temperature to obtain a chromium-doped lithium iron phosphate material . TH-908 is a ceramic dispersant produced by Shandong Taihe Water Treatment Co., Ltd.

[0034] The obtained lithium iron phosphate material has a capacity of 150mAh / g and a tap density of 1.1g / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com