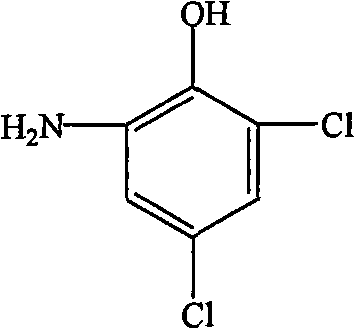

Method for preparing 2-amido-4,6-dichlorophenol

A technology of dichlorophenol and nitrophenol, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems that the preparation method has not yet been developed, and achieve easy recovery and application, easy availability of raw materials, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

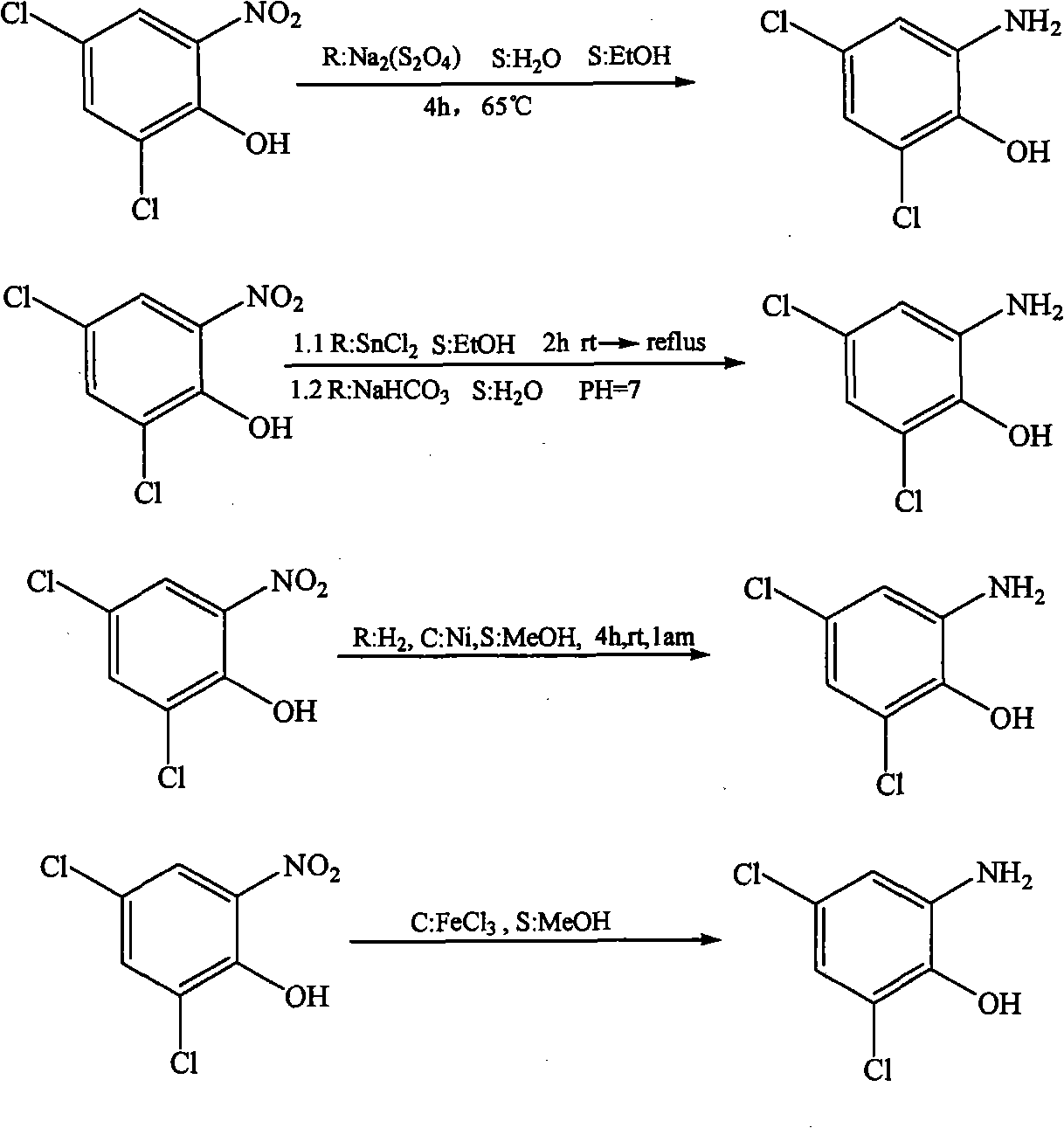

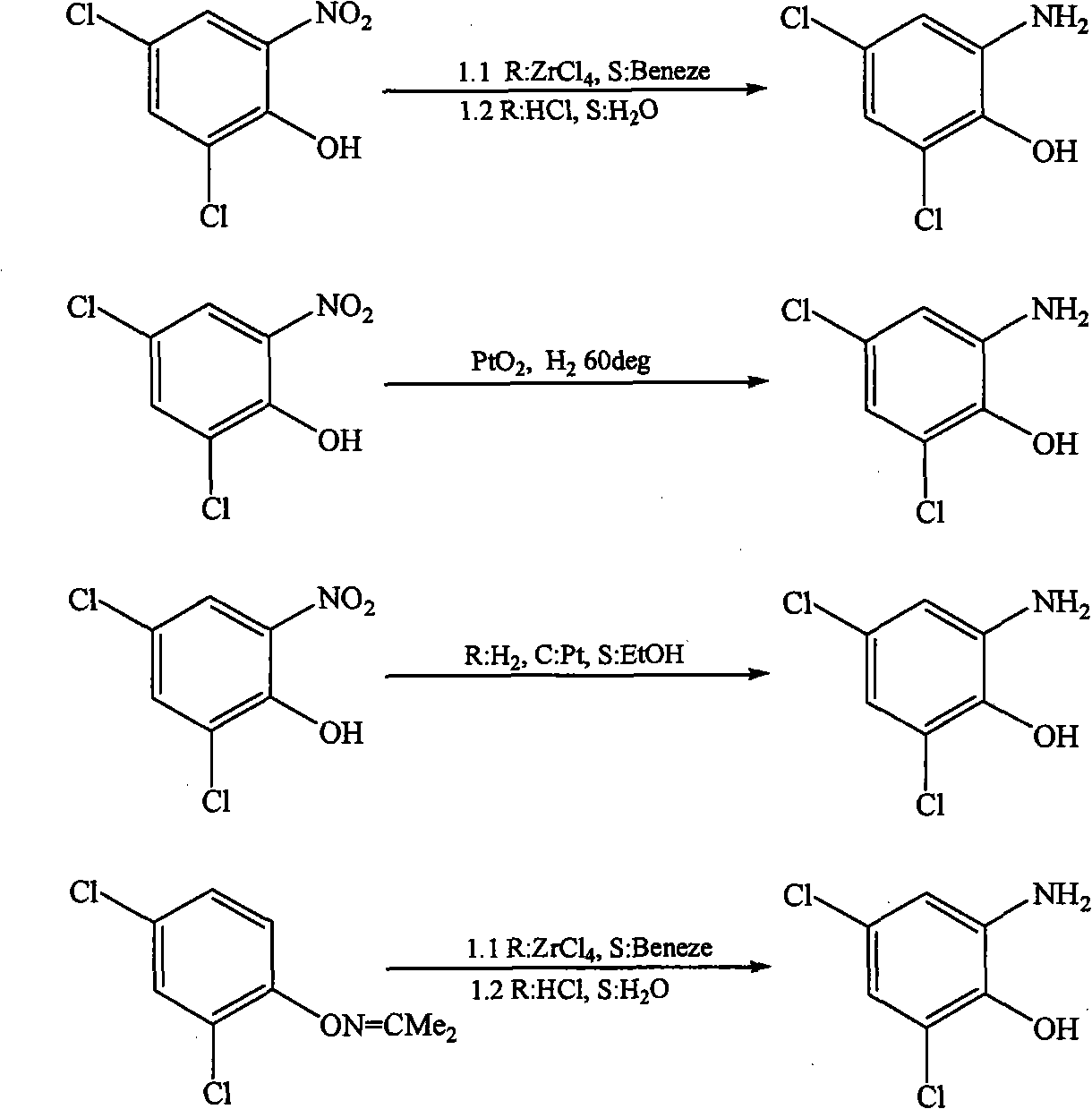

Method used

Image

Examples

Embodiment 1

[0025] Weigh 2.0g NiCl 2 Dissolve in 6.5mL distilled water, add 5g SiO to the beaker 2 (BET specific surface area = 198m 2 / g), soaked overnight, stirred in a 343K water bath until dry, baked at 373K for 6 hours, and roasted at 473K for 4 hours for later use. Under a 333K water bath, add 32.5mL of methanol, 5mL of ethanol, 7.5mL of hydrazine hydrate, 1.0g of sodium hydroxide, 1.0mL of distilled water and 1.0g of potassium borohydride into the three-necked flask, stir until dissolved, and weigh a certain amount of catalyst precursor The body was poured into a three-necked flask to obtain Ni-B / SiO 2 The samples were washed repeatedly with distilled water and ethanol in turn, and finally stored in ethanol for future use.

[0026] Add catalyst wet weight 2.35g, 2,4-dichloro-6-nitrophenol 7.5g and 150mL ethanol successively in 500ml autoclave, successively replace with nitrogen, hydrogen respectively 3 times, to remove air, pass into H 2 to 0.5MPa. Start stirring, the stirring...

Embodiment 2

[0028] Catalyst preparation operation process is the same as Example 1. SiO 2 (BET specific surface area = 198m 2 / g) is 5.0g, NiCl 2 2.0g, methanol 32.5mL, ethanol 5mL, hydrazine hydrate 7.5mL, sodium hydroxide 0.17g, distilled water 1.25mL and potassium borohydride 1.25g.

[0029] In a 500mL autoclave, 2.2g of catalyst wet weight, 7.5g of 2,4-dichloro-6-nitrophenol and 150ml of ethanol were successively added, followed by replacement with nitrogen and hydrogen for 3 times respectively to remove the air, and introduce H 2 to 0.6MPa. Start stirring, the stirring speed is 800r / min, and the autoclave is slowly heated to 333K. The reaction process was monitored by observing and recording the change of the pressure in the autoclave with time, and when the pressure no longer changed, the reaction was continued for 10 minutes and then stopped. Extract the solution in the kettle, filter out the catalyst (to be used mechanically next time), evaporate the filtrate to dryness under...

Embodiment 3

[0031] Catalyst preparation operation process is the same as Example 1. SiO 2 (BET specific surface area = 198m 2 / g) is 5.0g, NiCl 2 2.0g, baked at 373K for 6 hours, roasted at 573K for 4 hours, methanol 32.5mL, ethanol 5mL, hydrazine hydrate 7.5mL, sodium hydroxide 0.17g, distilled water 1.25mL and potassium borohydride 1.25g.

[0032]In a 500mL autoclave, 2.35g of catalyst wet weight, 7.5g of 2,4-dichloro-6-nitrophenol and 150mL of propanol were sequentially added, replaced with nitrogen and hydrogen for 3 times in order to remove the air, and introduced H 2 to 0.5MPa. Start stirring, the stirring speed is 800r / min, and the autoclave is slowly heated to 343K. The reaction progress was monitored by observing and recording the change of the pressure in the autoclave with time, and when the pressure no longer changed, the reaction was continued for 10 minutes and then stopped. Extract the solution in the kettle, filter out the catalyst (to be used mechanically next time),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com