Bicyclic phosphate-based triazine derivative flame retardant and preparation method thereof

A technology of bicyclic phosphate triazine and derivatives, applied in the field of bicyclic phosphate triazine derivative flame retardants and their preparation, can solve the problem of material mechanical and mechanical properties decline, uneven distribution of components, flame retardants Easy to absorb moisture and other problems, to achieve the effect of improving defects, easy availability of raw materials, and good migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

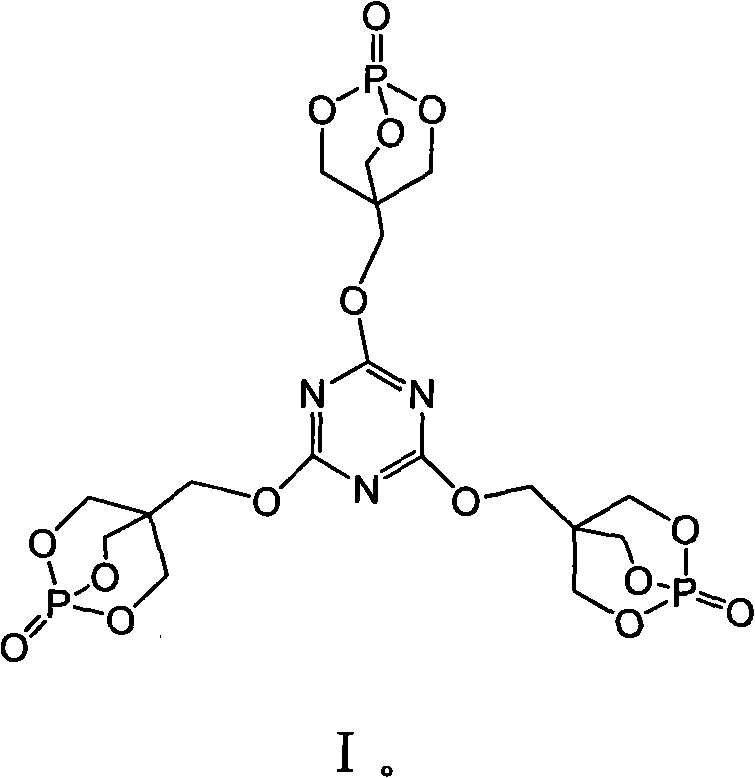

[0035] Under the protection of high-purity nitrogen (purity ≥ 99.9%), put 1.84g (10mmol) cyanuric chloride into the reactor, add 50mL N, N-dimethylacetamide, stir for 10 minutes to disperse the cyanuric chloride evenly , then add 6.10mL (35mmol) N, N-diisopropylethylamine and 5.40g (30mmol) PEPA, continue to stir for a period of time to make the reactant disperse evenly, after reacting at 40°C for 8 hours, raise the reaction temperature to 60°C ℃, after stirring and reacting for 10 hours, raise the reaction temperature to 110℃, and after stirring and reacting for 12 hours, stop the reaction. After drying for 48 hours, a triazine derivative flame retardant having a bicyclic phosphate group was obtained with a yield of 93.7%.

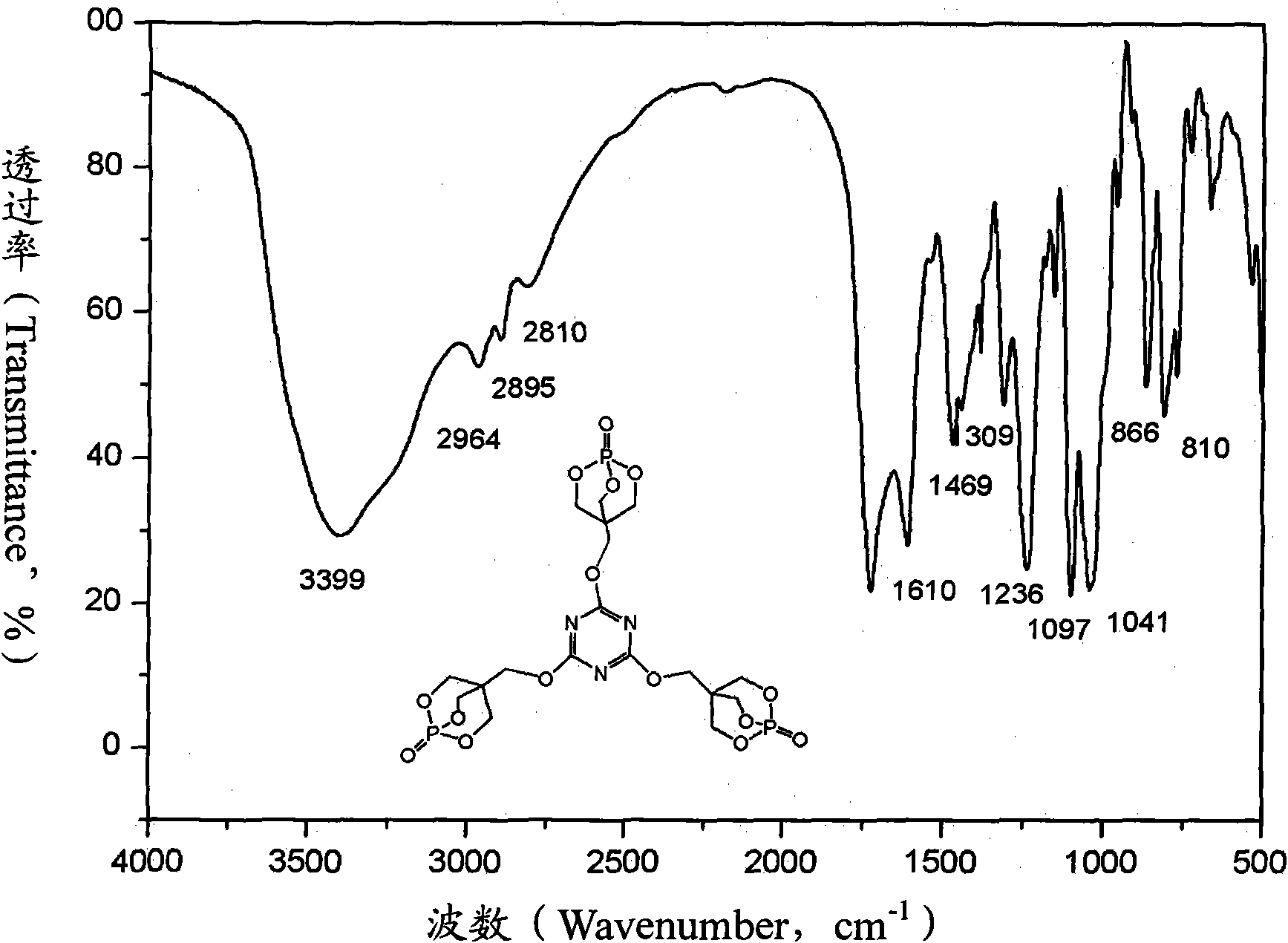

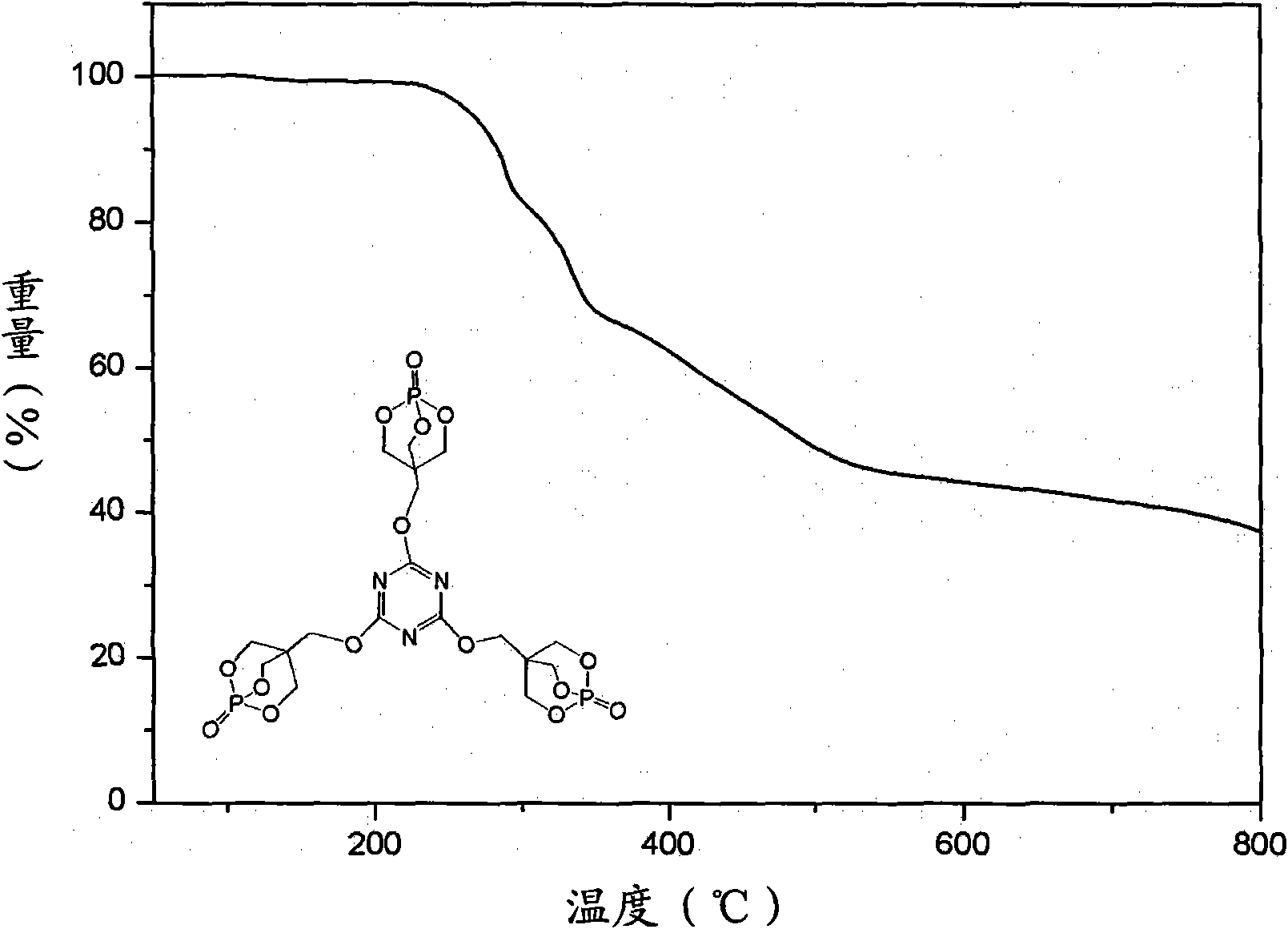

[0036] The above-mentioned prepared bicyclic phosphate group triazine derivative flame retardant is carried out infrared test, and the test instrument is NICOLET 6700; Potassium bromide compression tablet sample preparation; its infrared spectrum is as f...

Embodiment 2

[0040] Under the protection of high-purity nitrogen (purity ≥ 99.9%), put 1.84g (10mmol) cyanuric chloride into the reactor, add 50mL of dioxane, stir for 20 minutes to disperse the cyanuric chloride evenly, add 5.78mL (40mmol) triethylamine and 5.40g (30mmol) PEPA, continue to stir for a period of time to make the reactant disperse evenly, after reacting at 40°C for 12 hours, raise the reaction temperature to 60°C, stir and react for 12 hours, then increase the reaction temperature Temperature to 85°C, stirring reaction for 24 hours, stop the reaction, precipitate the reaction product with 1500mL acetone after cooling, wash with a large amount of acetone after suction filtration, and vacuum dry at 80°C for 48 hours to obtain a bicyclic phosphate ester structure bicyclic Phosphate-based triazine derivative flame retardant with a yield of 95.2%.

[0041] The above-mentioned prepared bicyclic phosphate-based triazine derivative flame retardant is subjected to infrared testing, t...

Embodiment 3

[0044] Under the protection of high-purity nitrogen (purity ≥ 99.9%), put 1.84g (10mmol) cyanuric chloride into the reactor, add 50mL of 1-methyl 2-pyrrolidone, stir for 10-30 minutes to disperse the cyanuric chloride evenly , add 6.10mL (35mmol) N, N-diisopropylethylamine and 5.40g (30mmol) PEPA, continue to stir for a period of time to disperse the reactants evenly, after reacting at 40°C for 8 hours, raise the reaction temperature to 60°C , after stirring for 8 hours, raise the reaction temperature to 120°C, and stop the reaction after stirring for 12 hours. After cooling, use 1000mL ethanol to precipitate the reaction product, wash it with a large amount of acetone after suction filtration, and dry it in vacuum at 80°C. After 48 hours, a bicyclic phosphate-based triazine derivative flame retardant was obtained with a yield of 94.1%.

[0045] The above-mentioned prepared bicyclic phosphate-based triazine derivative flame retardant is subjected to infrared testing, the test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com