Preparation method of composite electrode material using flap-like manganese dioxide nanocrystal to coat carbon nanotubes

A technology of nanotube compounding and manganese dioxide, which is applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of no investigation of electrochemical performance, achieve good electrochemical behavior, reduce internal resistance, and the effect of easy control of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

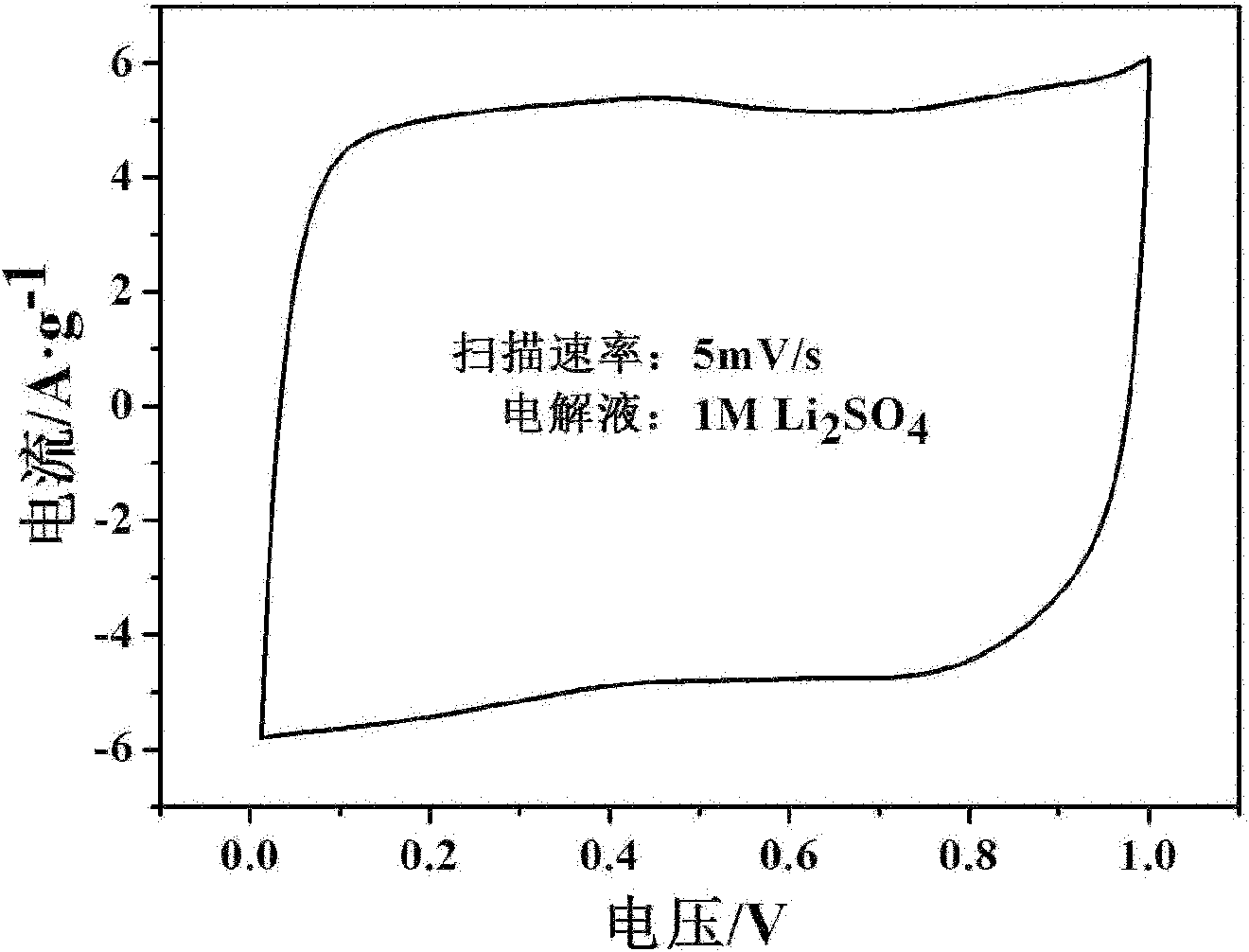

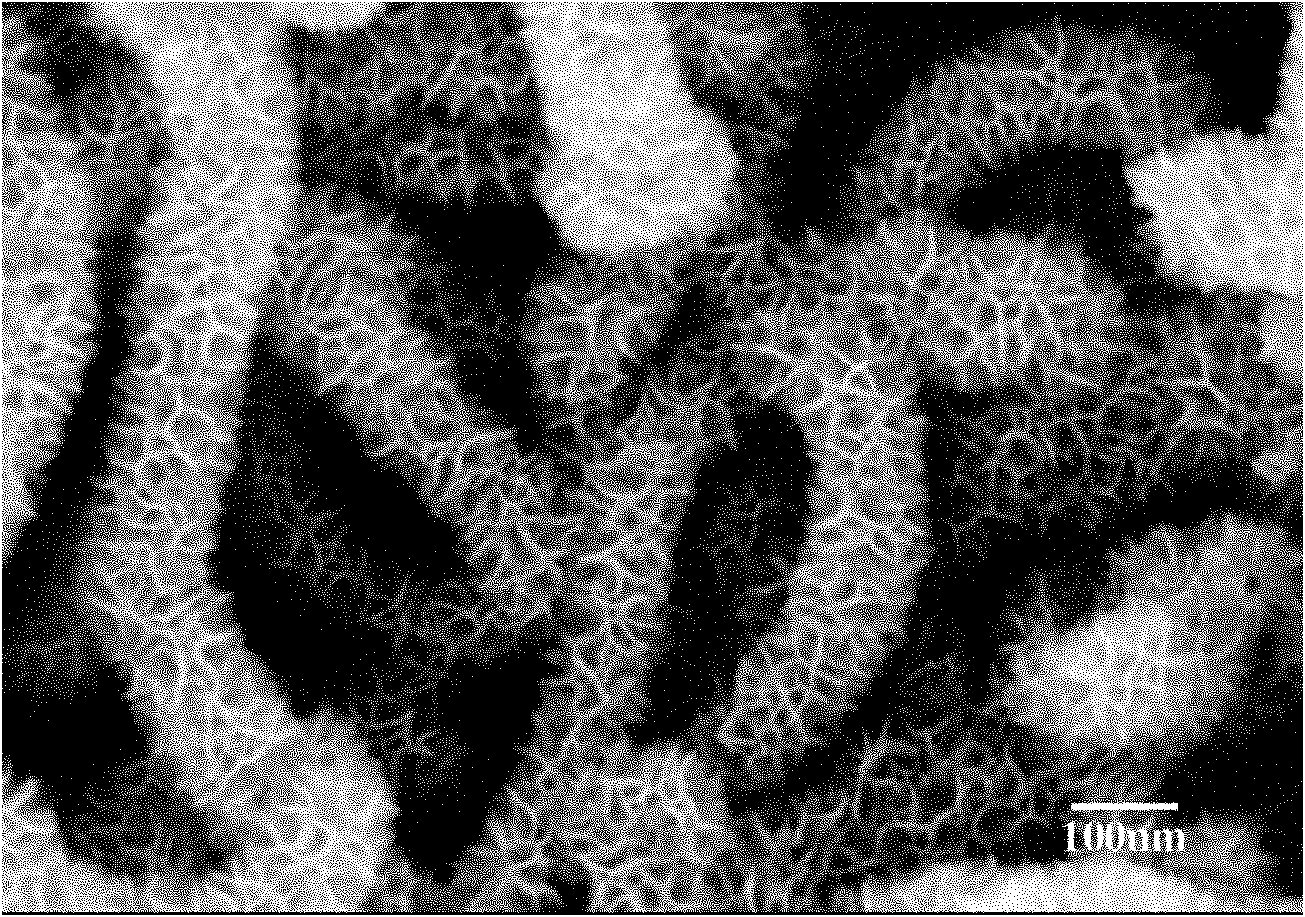

[0025] Take commercial MWCNTs (length 500nm ~ 2μm, diameter 20 ~ 40nm) ultrasonic dispersion in deionized water for 30min, add saturated potassium permanganate solution, wherein the volume ratio of potassium permanganate and deionized water is 5:1, The content of carbon nanotubes in the solution is 0.04g / ml. Hydrochloric acid was added dropwise to adjust the pH value of the solution to 0. After ultrasonically assisted reaction at 70°C for 3h, it was placed in a polytetrafluoroethylene-lined hydrothermal kettle and reacted at 140°C for 2h. After natural cooling, the product was repeatedly washed with deionized water and absolute ethanol, suction filtered, and vacuum-dried at 80° C. for 24 hours to obtain a composite material of flap-shaped manganese dioxide nanocrystals coated with carbon nanotubes. Grind the above materials thoroughly in a ball mill, hot press at 80°C and 9MPa for 30 minutes to form an electrode on the foamed nickel, and use the Pt electrode as the counter ele...

Embodiment 2

[0027]Take commercial MWCNTs (length 500nm ~ 2μm, diameter 20 ~ 30nm) ultrasonic dispersion in deionized water for 30min, add saturated potassium permanganate solution, wherein the volume ratio of potassium permanganate and deionized water is 5:1, The content of carbon nanotubes in the solution is 0.03g / ml. Hydrochloric acid was added dropwise to adjust the pH value to 0. After ultrasonically assisted reaction at 70°C for 4h, it was placed in a polytetrafluoroethylene-lined hydrothermal kettle and reacted at 140°C for 4h. After natural cooling, the product was repeatedly washed with deionized water and absolute ethanol, suction filtered, and vacuum-dried at 80° C. for 24 hours to obtain a composite material of flap-shaped manganese dioxide nanocrystals coated with carbon nanotubes. The above materials are fully ground in a ball mill, hot-pressed at 80°C and 9MPa for 30 minutes to form an electrode on a nickel foam, and a Pt electrode is used as a counter electrode, Ag / AgCl is ...

Embodiment 3

[0029] Take commercial MWCNTs (length 500nm~2μm, diameter 10~20nm) and ultrasonically disperse them in deionized water for 30min, then add saturated potassium permanganate solution, wherein the volume ratio of potassium permanganate to deionized water is 5:1, The content of carbon nanotubes in the solution is 0.02g / ml. Hydrochloric acid was added dropwise to adjust the pH value to 0. After ultrasonically assisted reaction at 70°C for 6h, it was placed in a polytetrafluoroethylene-lined hydrothermal kettle and reacted at 160°C for 6h. After natural cooling, the product was repeatedly washed with deionized water and absolute ethanol, suction filtered, and vacuum-dried at 80° C. for 24 hours to obtain a composite material of leaf-shaped manganese dioxide nanocrystals coated with carbon nanotubes. The above materials are fully ground in a ball mill, hot-pressed at 80°C and 9MPa for 30 minutes to form an electrode on a nickel foam, and a Pt electrode is used as a counter electrode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com