Quaternary phosphonium salt pillared layered zirconium phosphate material, and preparation method and application thereof

A technology of zirconium phosphate and quaternary phosphate salt, which is applied in the field of organic-inorganic hybrid materials and their preparation, can solve the problems of low temperature resistance, limited application scope, etc., and achieves good weather resistance, good stability and excellent weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

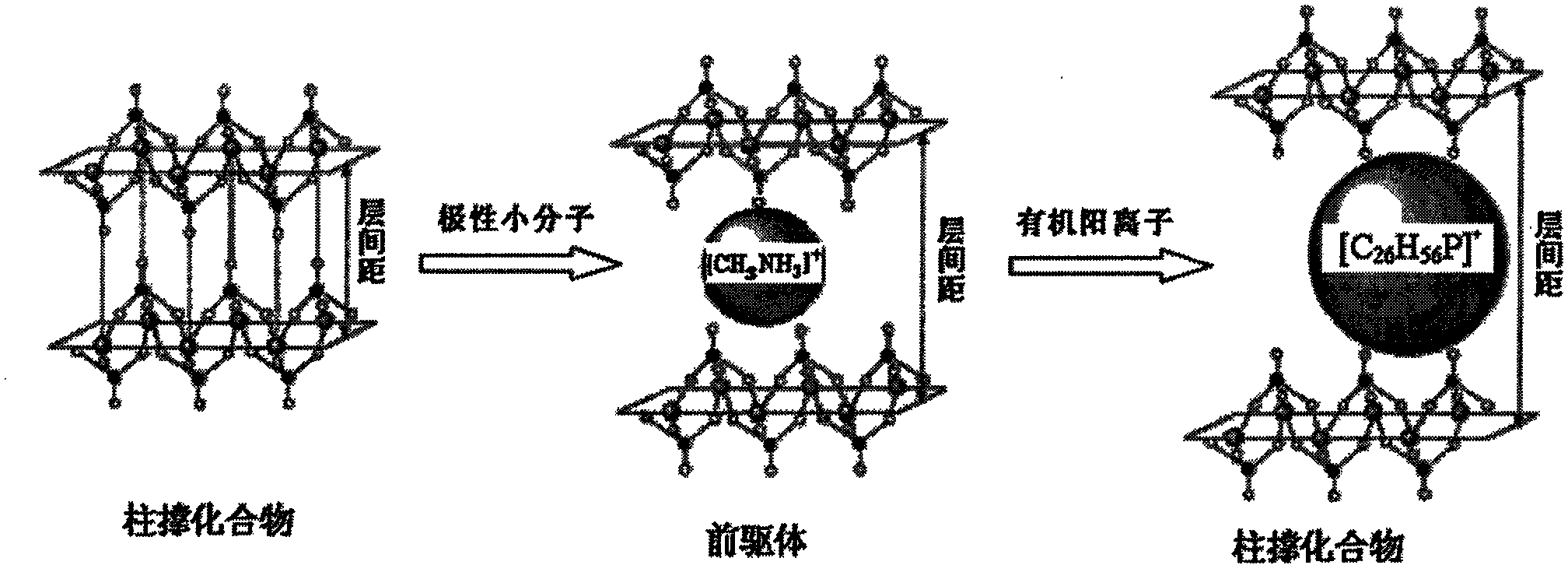

Method used

Image

Examples

Embodiment 1

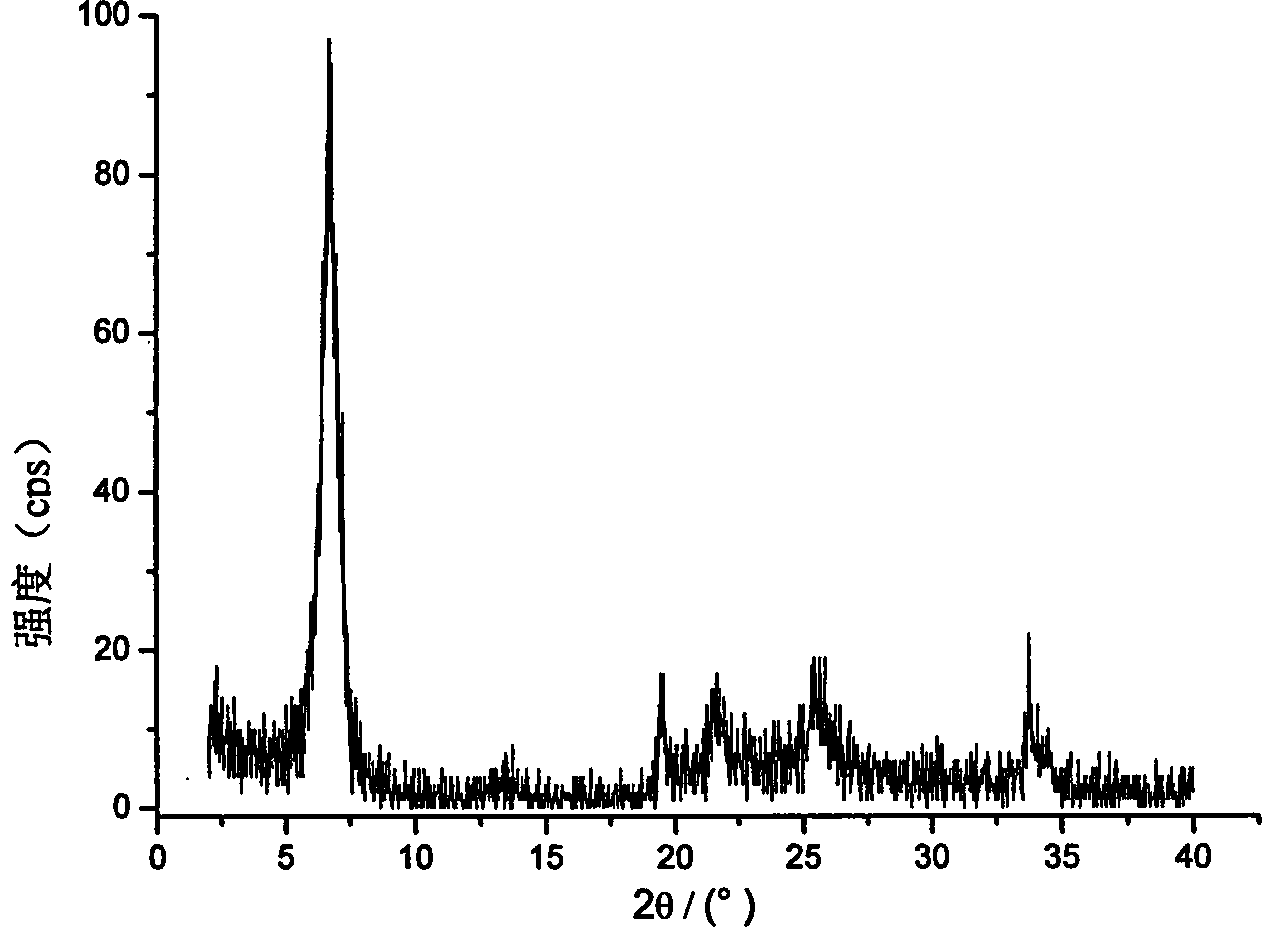

[0041] Weigh 5.82g (0.02mol) of layered α-ZrP and disperse it in 300mL of water. After the dispersion is complete, add 12g of 25% methylamine (MA) solution (containing 0.10mol of methylamine) to the dispersion, and dissolve it at 60°C. After stirring for 2h, MA-ZrP solution was obtained after stirring. Then add 8.12g (0.02mol) of dodecyltributylphosphorus bromide to the MA-ZrP solution, stir, react at 25°C for 6h, filter the reaction product, wash the solid with distilled water until it is detected with silver nitrate solution Filtrate free of bromide ions, vacuum at 90°C (vacuum degree is 2×10 4 Pa) drying for 24h to obtain the initial product, then superfinely pulverized to an average particle diameter of less than 5 microns to obtain a quaternary phosphonium pillared layered zirconium phosphate material (according to the TGA analysis results, the chemical formula is ). The test results are shown in Table 1.

Embodiment 2

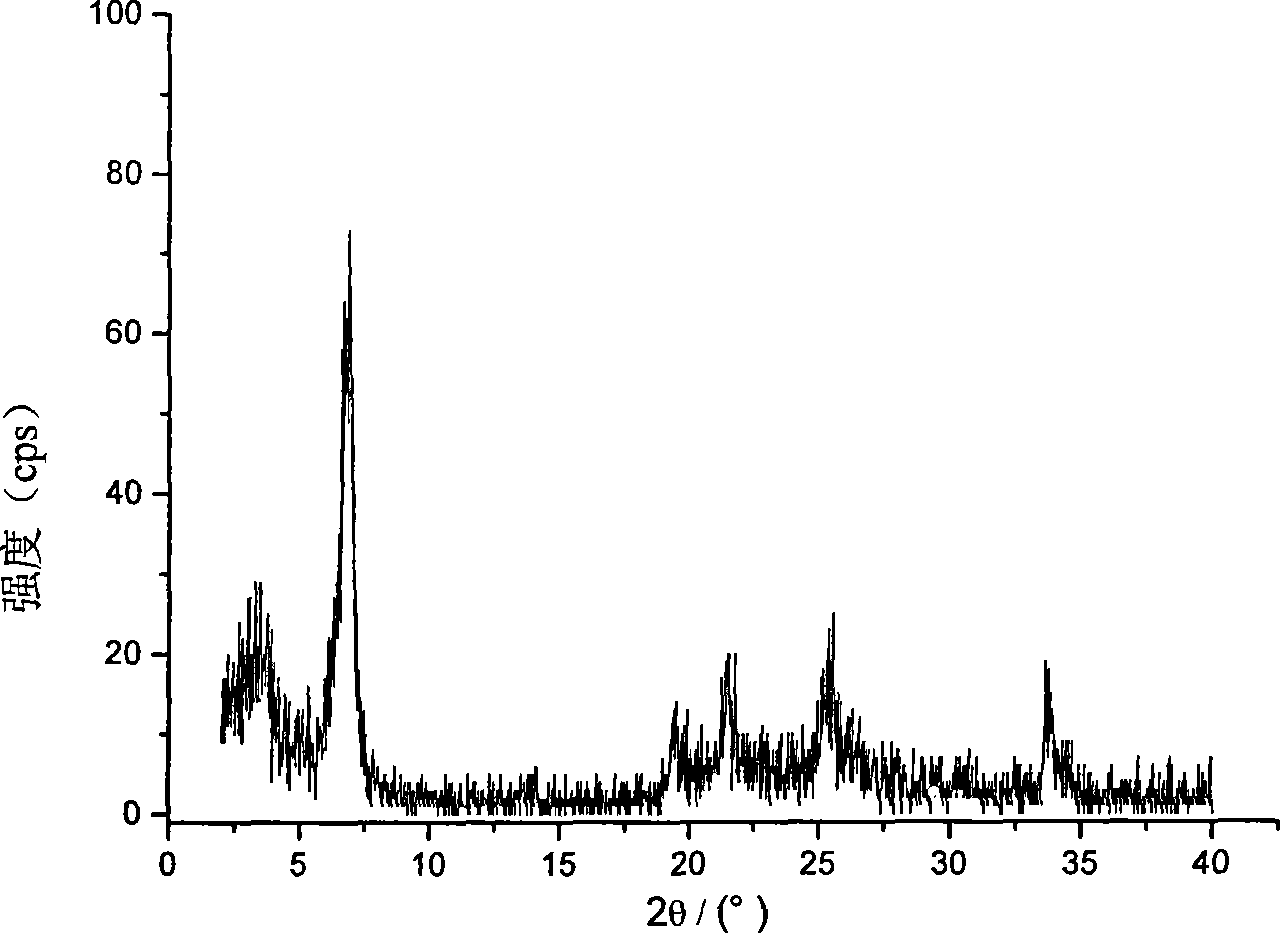

[0043] Weigh 5.82g (0.02mol) of α-ZrP and disperse it in 300mL of water. After the dispersion is complete, add 6g of 25% methylamine (MA) solution (containing 0.05mol of methylamine) to the dispersion, and stir at 65°C for 3h , and the MA-ZrP solution was obtained after stirring. Then add 32.48g (0.08mol) dodecyltributylphosphorous chloride to the MA-ZrP solution, stir, react at 30°C for 5h, filter the reaction product, wash the solid with distilled water until it is detected with silver nitrate solution Filtrate free of chloride ions, vacuum at 80°C (vacuum degree is 2×10 4 Pa) drying for 20h to obtain the initial product, then superfinely pulverized to an average particle diameter less than 5 microns to obtain a quaternary phosphonium pillared zirconium phosphate material (according to the TGA analysis results, the chemical formula is ). The test results are shown in Table 1.

Embodiment 3

[0045] Take by weighing 5.82g (0.02mol) α-ZrP and be dispersed in 300mL water, treat to disperse completely, add 2.4g (0.02mol) 25% methylamine (MA) solution (containing methylamine 0.02mol) in this dispersion liquid, in Stir at 40°C for 1 h, and after stirring, a MA-ZrP solution is obtained. Then add 0.0894g (0.0002mol) dedecyltriphenylphosphine bromide to the MA-ZrP solution, stir, react at 20°C for 4h, filter the reaction product, wash the solid with distilled water until the filtrate is detected with silver nitrate solution No bromide ions, vacuum at 80°C (vacuum degree is 2×10 4 Pa) drying for 24h to obtain the initial product, then superfinely pulverized to an average particle size less than 3 microns, to obtain a quaternary phosphonium pillared zirconium phosphate material (according to the TGA analysis results, the chemical formula is ). The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com