Method for preparing cuprous oxide powder by copper-contained electroplating sludge pressurizing hydrogen reduction

A technology of cuprous oxide and electroplating sludge, which is applied in chemical instruments and methods, copper oxide/copper hydroxide, sludge treatment, etc. Simple operation and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

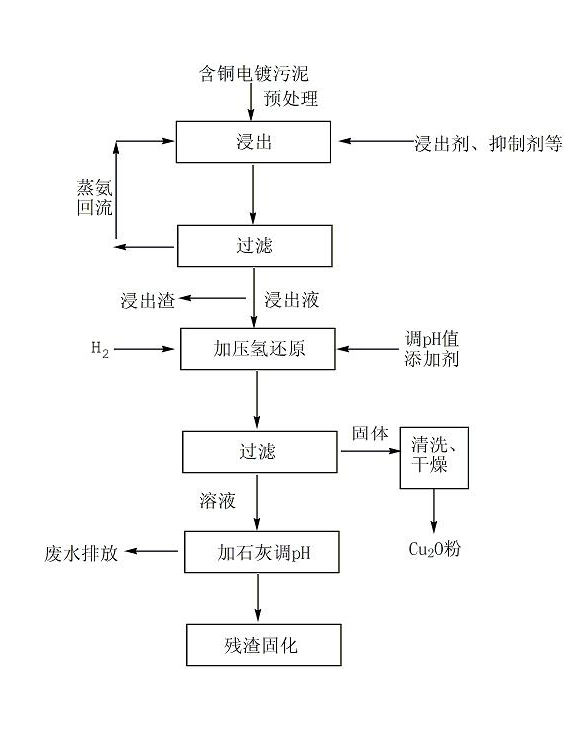

[0028] See figure 1 , the method for preparing cuprous oxide powder by pressurized hydrogen reduction of copper-containing electroplating sludge of the present embodiment comprises the following steps:

[0029] ①Pretreatment: Dry 100kg of copper-containing electroplating sludge in a sludge dryer at 120°C for 2 hours, then grind the dried sludge in a grinder, pass through a 200-mesh sieve, and remove large particles and sand grain.

[0030] See Table 1, the metal and its content in the copper-containing electroplating sludge after the above-mentioned drying are shown in the following table:

[0031] Table 1 Main components and content of copper-containing electroplating dry sludge

[0032] Element

Ni

Cu

Zn

Cr

Mg

Fe

Ca

Copper-containing electroplating sludge (%)

0.0053

16.4

0.005

0.004

1.33

0.723

10.8

[0033] ②Ammonia leaching: Transfer the electroplating sludge pretreated in step ① to the reaction tank...

Embodiment 2)

[0041] The electroplating sludge treated in this embodiment is the same as in Example 1, and the method for preparing cuprous oxide powder by pressurized hydrogen reduction of copper-containing electroplating sludge in this embodiment differs from the method in Example 1 in that:

[0042] Step 2. In the reaction tank, adding concentration is 900 liters of ammoniacal liquor and 600 kilograms of ammonium sulfate solids of 10 mol / L, wherein n(NH 3 ·H 2 O): n((NH 4 ) 2 SO 4 ) = 2:1, the mass ratio of ammonia water (referring to the aqueous solution of ammonium hydroxide) to copper-containing electroplating sludge, that is, the liquid-solid ratio is 8.4:1.

[0043] In step ③, when the pressurized hydrogen reduction reaction is carried out, after the solution is loaded into the autoclave, the lid of the autoclave is covered, nitrogen is introduced to replace the air in the autoclave, and then hydrogen is introduced to replace the nitrogen in the autoclave; then continue to introd...

Embodiment 3)

[0045] The electroplating sludge treated in this embodiment is the same as in Example 2, and the method for preparing cuprous oxide powder by pressurized hydrogen reduction of copper-containing electroplating sludge in this embodiment differs from the method in Example 2 in that:

[0046] In step ③, add 10% sulfuric acid solution to the leaching solution obtained in step ② and mix evenly until the pH value of the leaching solution is 6.2, put the solution in the autoclave and cover the kettle lid, first pass in nitrogen to replace the air in the kettle, Pass into hydrogen again, replace the nitrogen in the still; Then continue to pass into hydrogen until the pressure in the still rises to 2MPa, stop ventilation and open the magnetic stirring device at this moment, set the rotating speed to be 500r / min, turn on the heating device again, until the temperature rises to 140°C, and when the pressure in the kettle begins to drop, start timing, and react for 60 minutes. During the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com