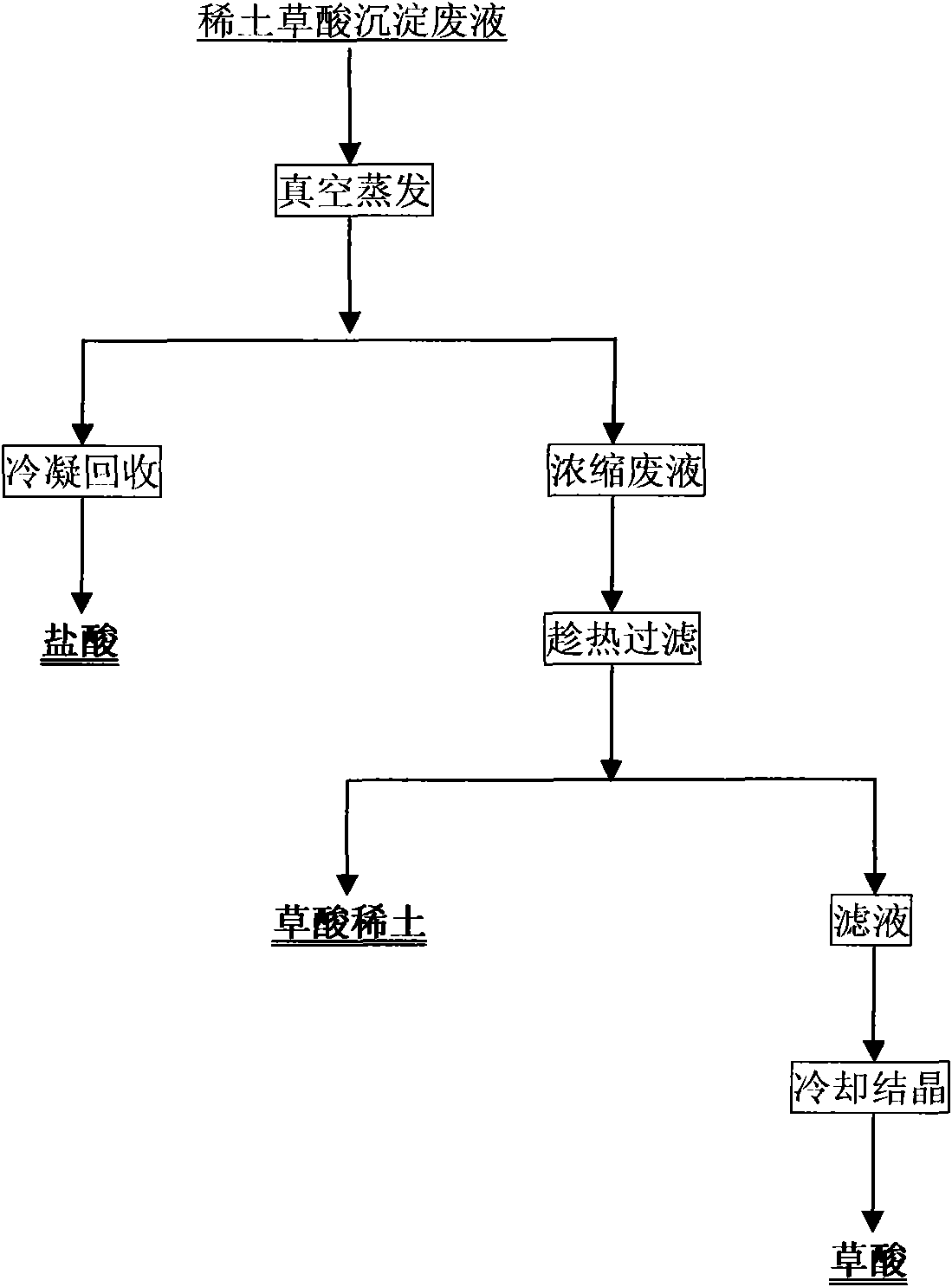

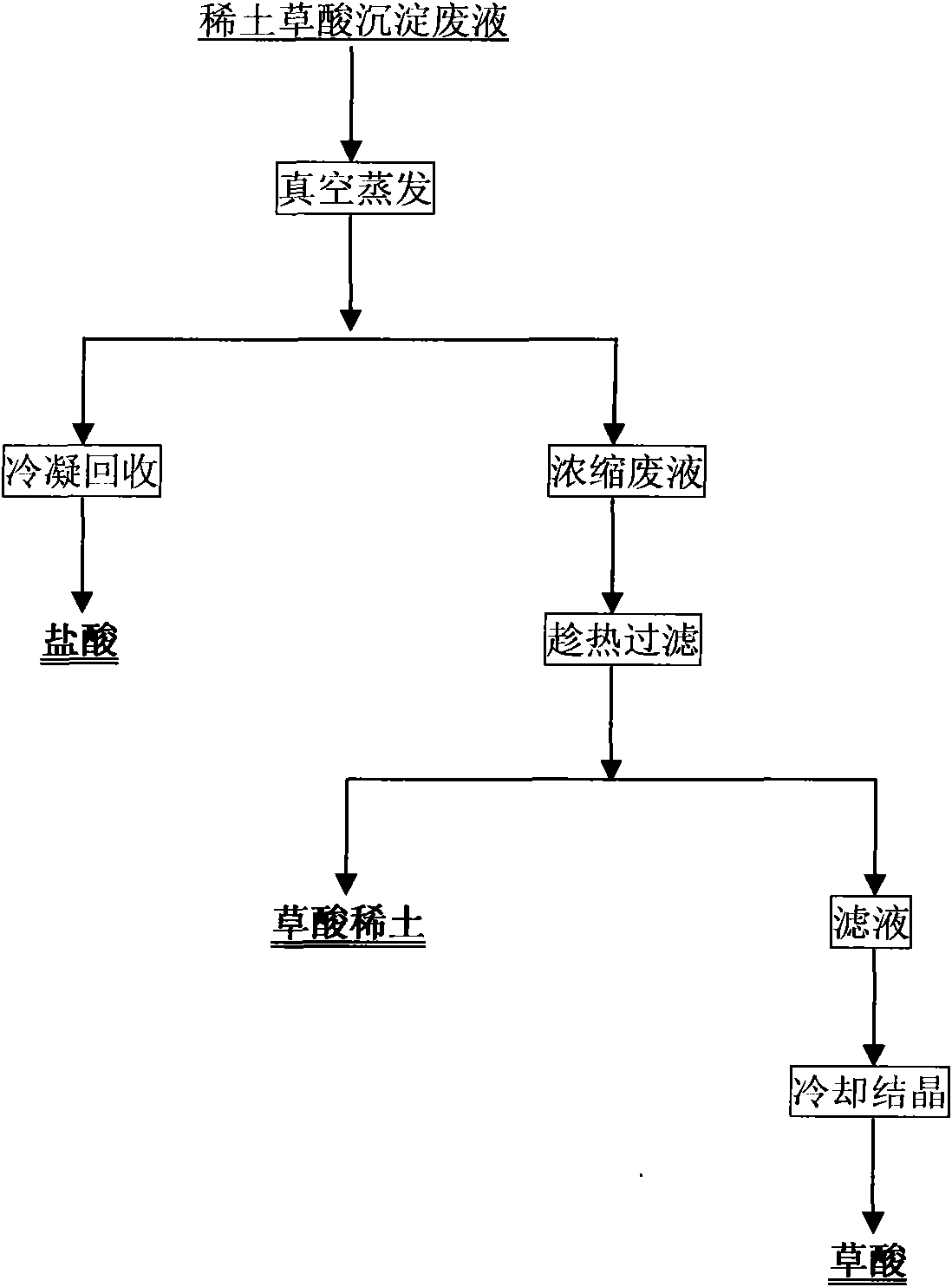

Method for comprehensively recycling rare earth oxalate precipitate waste liquid

A technology of oxalic acid precipitation and waste liquid, applied in the field of rare earth, can solve the problem of reducing the evaporation temperature of dilute acid, and achieve the effects of less acid gas leakage, prolonging service life, and reducing processing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] will contain C HCl =1.88mol / L, C 草酸 =15.1g / L, 4m of dysprosium oxalate precipitation waste liquid of REO=0.77g / L 3 join 5m 3 After heating to 50°C in a jacketed enamel reaction tank, evaporate and concentrate under the condition of -0.08Mpa (table) and gradually heat up to a maximum of 95°C to evaporate and recover hydrochloric acid; when the volume of waste liquid is concentrated to 8%, stop evaporation; concentrate The remaining liquid is filtered while it is hot at 70°C. After recovering dysprosium oxalate, the filtrate is cooled and crystallized to recover oxalic acid; the residual liquid after recovering oxalic acid is incorporated into the next evaporation and concentrated. Total recovered C HCl =1.74mol / L hydrochloric acid 3.68m 3 , the recovery rate of hydrochloric acid is 85.15%; 50kg of oxalic acid is recovered, and the recovery rate of oxalic acid is 88.78%; the recovered dysprosium oxalate is equivalent to REO 3.02kg, and the recovery rate of dysprosium ...

Embodiment 2

[0029] will contain C HCl =0.86mol / L, C 草酸 =10.6g / L, REO=0.71g / L praseodymium neodymium oxalate precipitation waste liquid 4m 3 join 5m 3 After heating to 50°C in a jacketed enamel reaction tank, evaporate and concentrate under the condition of -0.03MPa (table) and gradually heat up to a maximum of 105°C to recover hydrochloric acid by evaporation; when the volume of waste liquid is concentrated to 5%, stop evaporation; after concentration The remaining solution is filtered while hot at 95°C, and after recovering praseodymium and neodymium oxalate, the filtrate is cooled and crystallized to recover oxalic acid; the residual solution after recovering oxalic acid is incorporated into the next evaporation and concentration. Total recovered C HCl =0.82mol / L hydrochloric acid 3.8m 3 , the recovery rate of hydrochloric acid is 90.58%; 32kg of oxalic acid is recovered, and the recovery rate of oxalic acid is 75.47%; the recovery rate of praseodymium neodymium oxalate is equivalen...

Embodiment 3

[0031] will contain C HCl =2.44mol / L, C 草酸 =28.3g / L, yttrium europium oxalate precipitation waste liquid 4m of REO=0.83g / L 3 join 5m 3 After heating to 50°C in the enamel reaction tank, evaporate and recover hydrochloric acid under the conditions of -0.01MPa (table) and 50°C. When the waste liquid volume is concentrated to 30%, stop evaporation; the concentrated residual liquid is filtered while hot at 50°C After recovering yttrium and europium oxalate, the filtrate is cooled and crystallized to recover oxalic acid; the raffinate after recovery of oxalic acid is incorporated into the next evaporation and concentration. Total recovered C HCl =2.04mol / L hydrochloric acid 3.76m 3 , the recovery rate of hydrochloric acid is 78.59%; 53kg of oxalic acid is recovered, and the recovery rate of oxalic acid is 46.8%; 2.13kg of yttrium europium oxalate (calculated as REO) is recovered, and the recovery rate of yttrium europium oxalate is 64.16%; The index of impurity content in ", t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com