Preparation of spherical lithium iron phosphate material and lithium ion battery using spherical lithium iron phosphate material

A lithium-ion battery and lithium iron phosphate technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of wide particle size distribution range, hindering the application of materials, and large crystal particle size, so as to simplify the ball milling process and improve Processability, effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Measure 1000ml deionized water, put it into a beaker, weigh 1215g iron nitrate (Fe(NO 3 ) 3 9H 2 O) and 6.5gMgCl 2 Dissolve in deionized water to prepare solution A, then measure 1000ml deionized water, put it into another beaker, weigh 355g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), to prepare solution B. Get another beaker, the ammonia solution that 1000ml concentration is housed is 3.5mol / L, as complexing agent C. Then solution A, solution B and complexing agent C were pumped into the reaction kettle at a flow rate of 80ml / min through a metering pump, and then reacted for 10 hours at a temperature of 70°C, and the rotation speed of the reaction kettle was 85r / min. After the reaction is finished, the precipitate is centrifugally filtered, washed and dried to obtain spherical ferric phosphate.

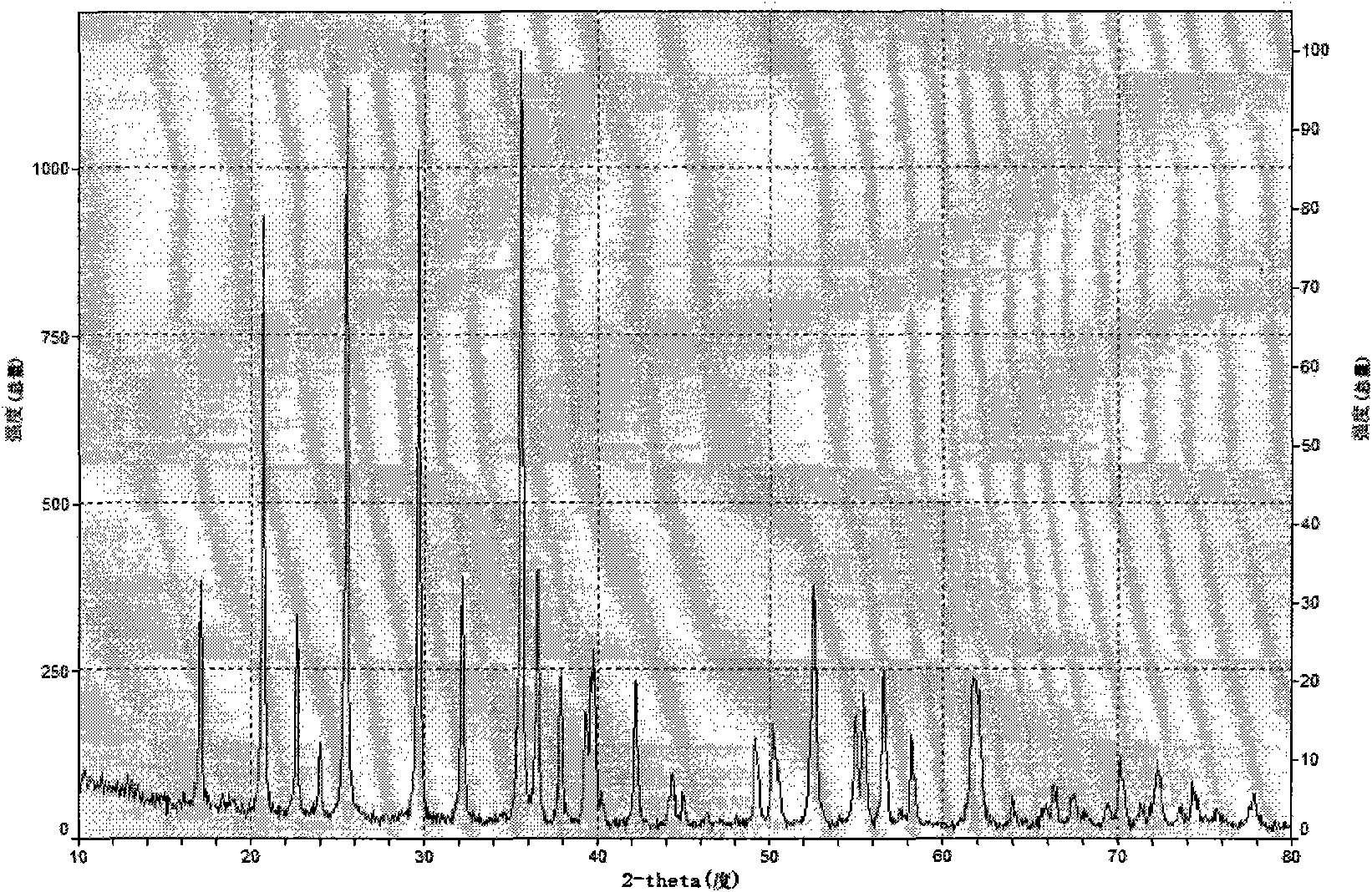

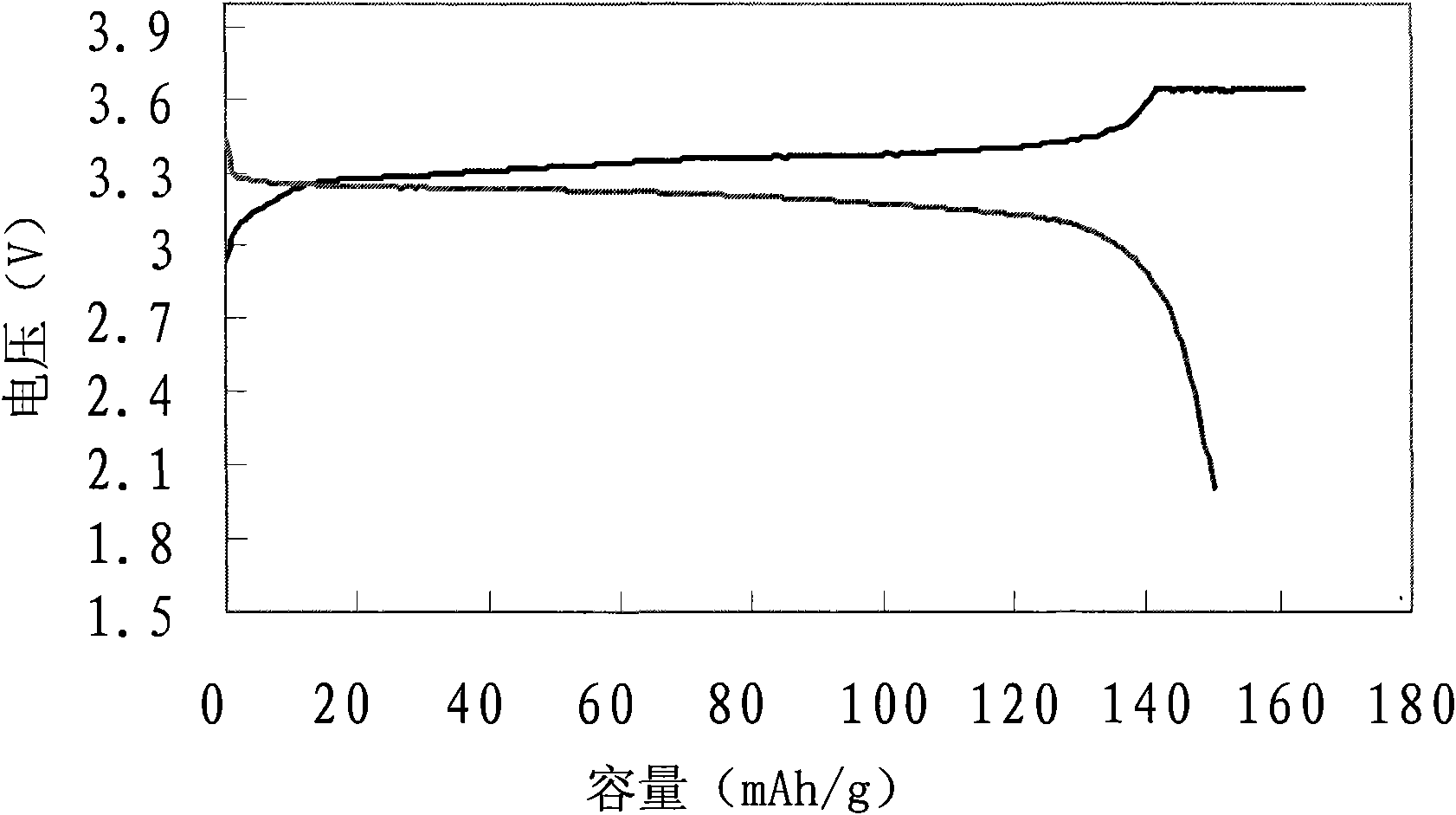

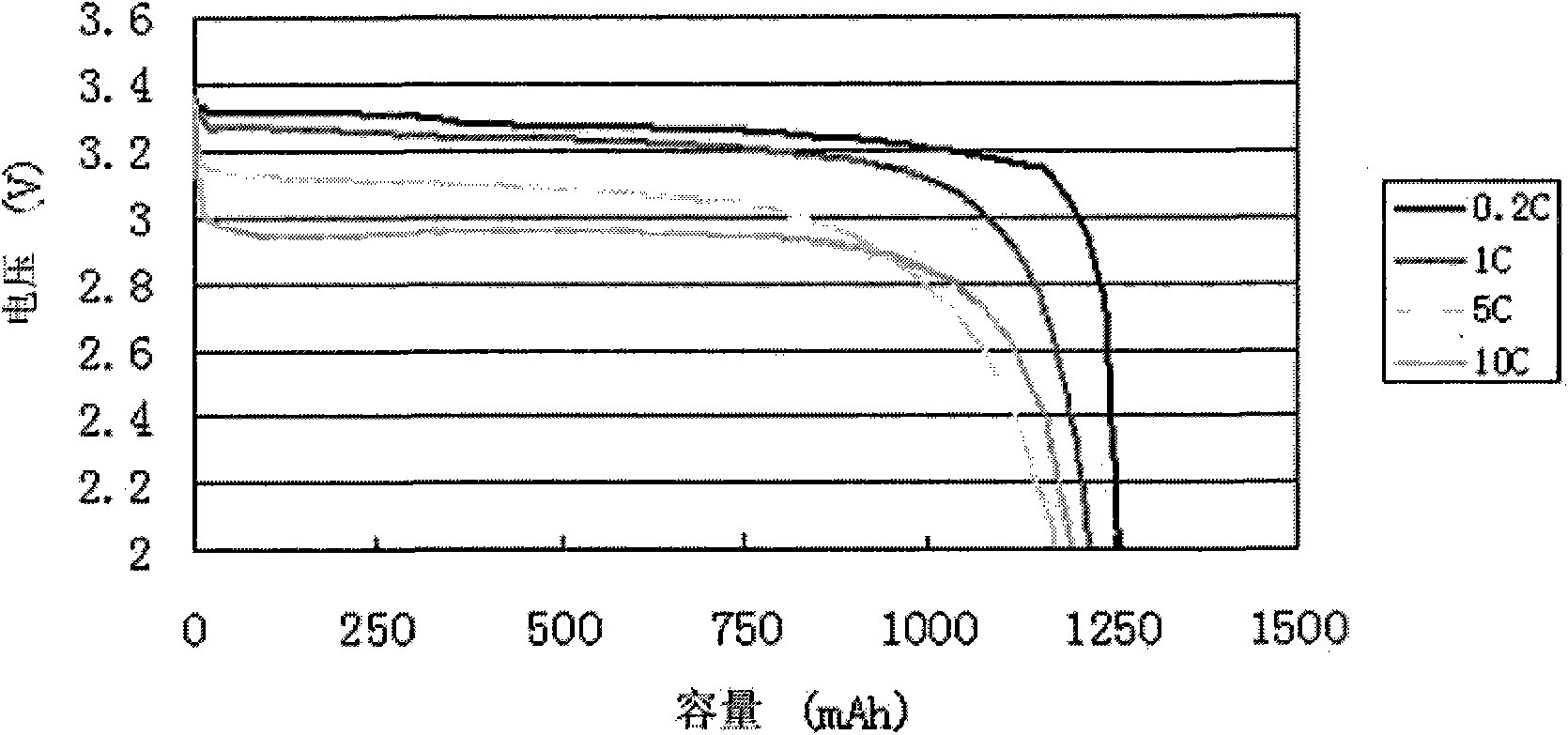

[0023] Weigh 450g iron phosphate (FePO 4 2H 2 O), 270g lithium carbonate (Li 2 CO 3 ), 50g of glucose and 45g of sucrose were added to the ball mill, and ball m...

Embodiment 2

[0026] Measure 1000ml deionized water, put it into a beaker, weigh 1215g iron nitrate (Fe(NO 3 ) 3 9H 2 O) and 6gAlCl 3 Dissolve in deionized water to prepare solution A, then measure 1000ml deionized water, put it into another beaker, weigh 355g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), the solution B prepared. Get another beaker, the ammonia solution that 1000ml concentration is housed is 3.5mol / L, as complexing agent C. Then solution A, solution B and complexing agent C were pumped into the reaction kettle at a flow rate of 80ml / min through a metering pump, and then reacted for 10 hours at a temperature of 70°C, and the rotation speed of the reaction kettle was 85r / min. After the reaction is finished, the precipitate is centrifugally filtered, washed and dried to obtain spherical ferric phosphate.

[0027] Weigh 450g iron phosphate (FePO 4 2H 2 O), 270g lithium carbonate (Li 2 CO 3 ), 45g of glucose and 40g of sucrose were added into a ball mill and milled ...

Embodiment 3

[0030] Measure 1000ml deionized water, put it into a beaker, weigh 1215g iron nitrate (Fe(NO 3 ) 3 9H 2 O and 9gTiCl 4 Dissolve in deionized water to prepare solution A, then measure 1000ml deionized water, put it into another beaker, weigh 355g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), to prepare solution B. Get another beaker, the ammonia solution that 1000ml concentration is housed is 3.5mol / L, as complexing agent C. Then solution A, solution B and complexing agent C were pumped into the reaction kettle at a flow rate of 80ml / min through a metering pump, and then reacted for 10 hours at a temperature of 70°C, and the rotation speed of the reaction kettle was 85r / min. After the reaction is finished, the precipitate is centrifugally filtered, washed and dried to obtain spherical ferric phosphate.

[0031] Weigh 450g iron phosphate (FePO 4 2H 2 O), 270g lithium carbonate (Li 2 CO 3 ), 55g of glucose and 40g of sucrose were added to the ball mill, and ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com