Gas separation adsorbent for pressure swing adsorption process and preparation method and application thereof

A pressure swing adsorption and gas separation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large equipment investment and high operating costs, and achieve strong economic practicability, improved desorption rate, and high efficiency. Effects of Separation Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

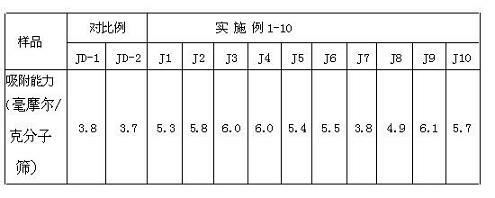

Examples

Embodiment 1

[0037] Weigh 11.7 grams of CuCl 2 , 28 grams of small-grained NaY powder, 10.5 grams of attapulgite, 13.5 grams of pseudo-boehmite, mixed with 25ml of hydrochloric acid solution with a mass concentration of 3%, kneaded and extruded, dried at 120°C for 6 Hours, according to the condition of 10℃ / min, the temperature is programmed to 450℃ for 2 hours, the adsorbent is recorded as J-1.

Embodiment 2

[0039] Weigh 44 grams of aluminum sol with 21% solid content, 1.5 grams of Yanggan clay, 93.8 grams of nano NaY powder, and CuCl 2 67 grams (analytical grade) mixed uniformly, grind and refine, add 96ml of 2% nitric acid solution, knead and extrude the bar, dry it at 110℃ for 10 hours, program it to 350℃ at 10℃ / min and roast 4 Hours, the adsorbent is recorded as J-2.

Embodiment 3

[0041] Weigh 220 grams of small-grained NaY powder and dissolve it in 0.1-0.2mol concentration of Cu(NO 3 ) 2 The exchange liquid is exchanged, filtered and washed 3-4 times at room temperature. The filter cake is dried at 120°C for 24 hours, programmed to heat up to 500°C at 10°C / min, and roasted for 1-2 hours for later use. Weigh 28.2 grams of the above roasted sample, mix with 20.3 grams of cuprous chloride (analytical purity), then mix with 0.56 grams of Yanggan clay with a solid content of 80% and 13.2 grams of pseudo-boehmite, and add 26ml of mass concentration to 2% hydrochloric acid solution, kneaded, extruded, and then dried at 120 ℃, calcined at 400 ℃ for 4 hours, denoted as J-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com