Method for preparing Fe2O3 and Fe3O4 nano materials by taking F2<2+> salt as raw material

A nanomaterial, fe2o3 technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of large environmental pollution, high production cost, high reaction temperature, etc., and achieve the effect of low cost, simple equipment, and simplified reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] α-Fe 2 O 3 -Preparation of phenolic resin composite nanoparticles

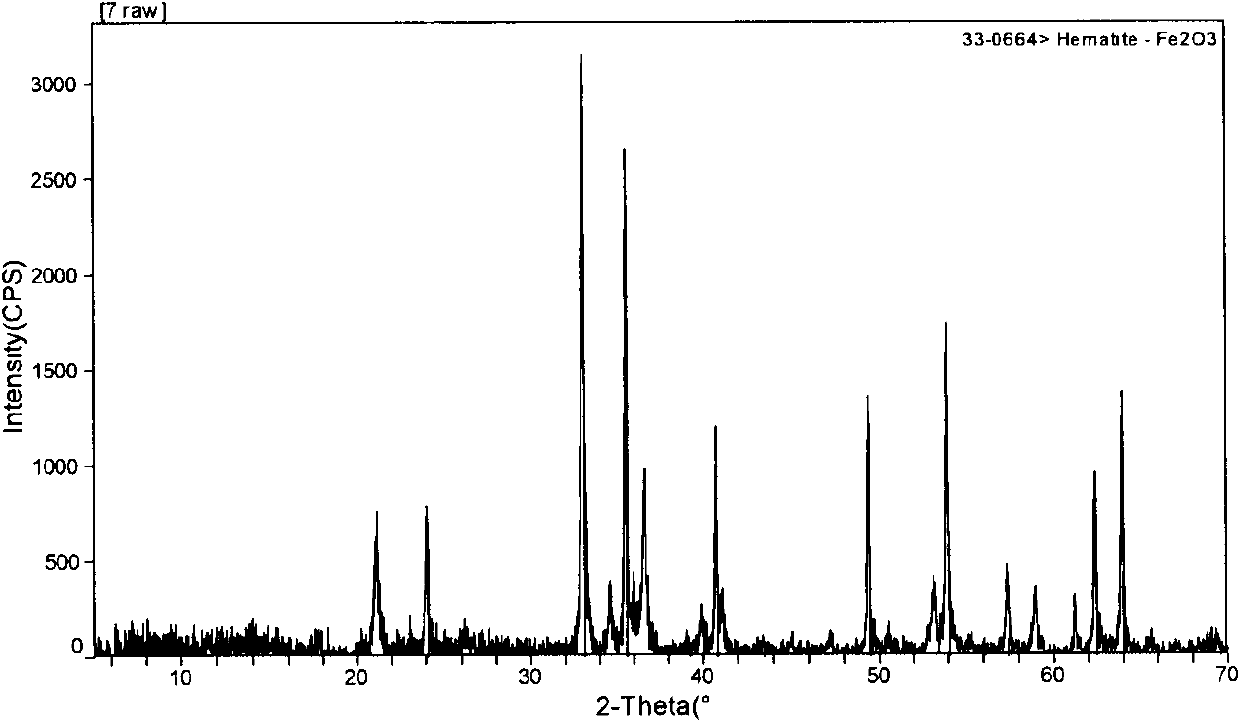

[0028] Step: 1) Add 0.2mmol FeSO 4 , 0.025mmol (CH 2 ) 6 N 4 , 0.05mmol of C 6 H 5 OH and 15ml of deionized water are mixed uniformly and put into the reaction kettle; 2) Place it in a thermostat and heat it at 160℃ for 6 hours; 3) Take out the container and let it cool to room temperature; alternately wash with deionized water and absolute ethanol The product is synthesized, and the product is obtained after low-temperature drying. Figure 4 Shown is the X-ray powder diffraction pattern of the obtained sample. It can be seen from the figure that the sample is α-Fe 2 O 3 -Phenolic resin composite nanoparticles, the size of the particles is 25±5nm.

Embodiment 2

[0030] Nano α-Fe 2 O 3 And preparation of FeO(OH) particles

[0031] Step: 1) Add 0.2mmol FeSO 4 , 0.025mmol (CH 2 ) 6 N 4 , 0.05mmol of C 6 H 5 OH and 15ml of absolute ethanol are mixed uniformly and put into the reaction kettle; 2) Place it in a thermostat and heat it at a constant temperature of 160°C for 6 hours; 3) After cooling, separation and drying, the nano α-Fe can be prepared 2 O 3 And FeO(OH) particles.

Embodiment 3

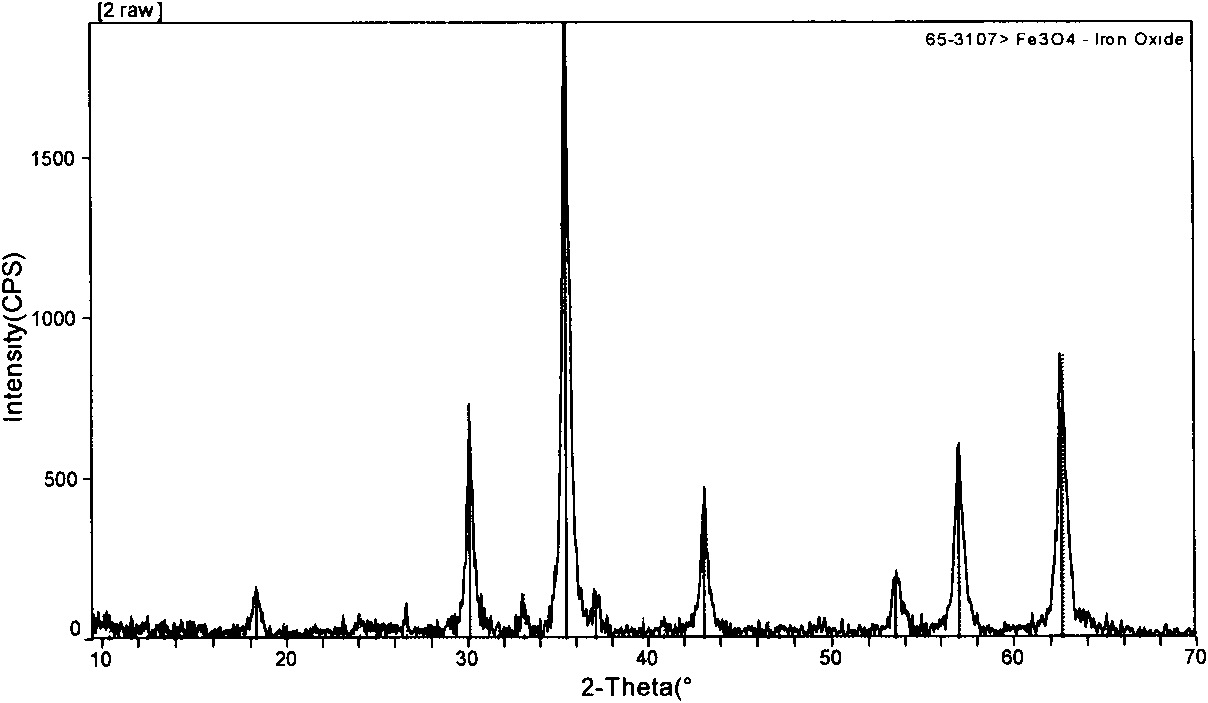

[0033] Fe 3 O 4 Preparation of nanoparticles

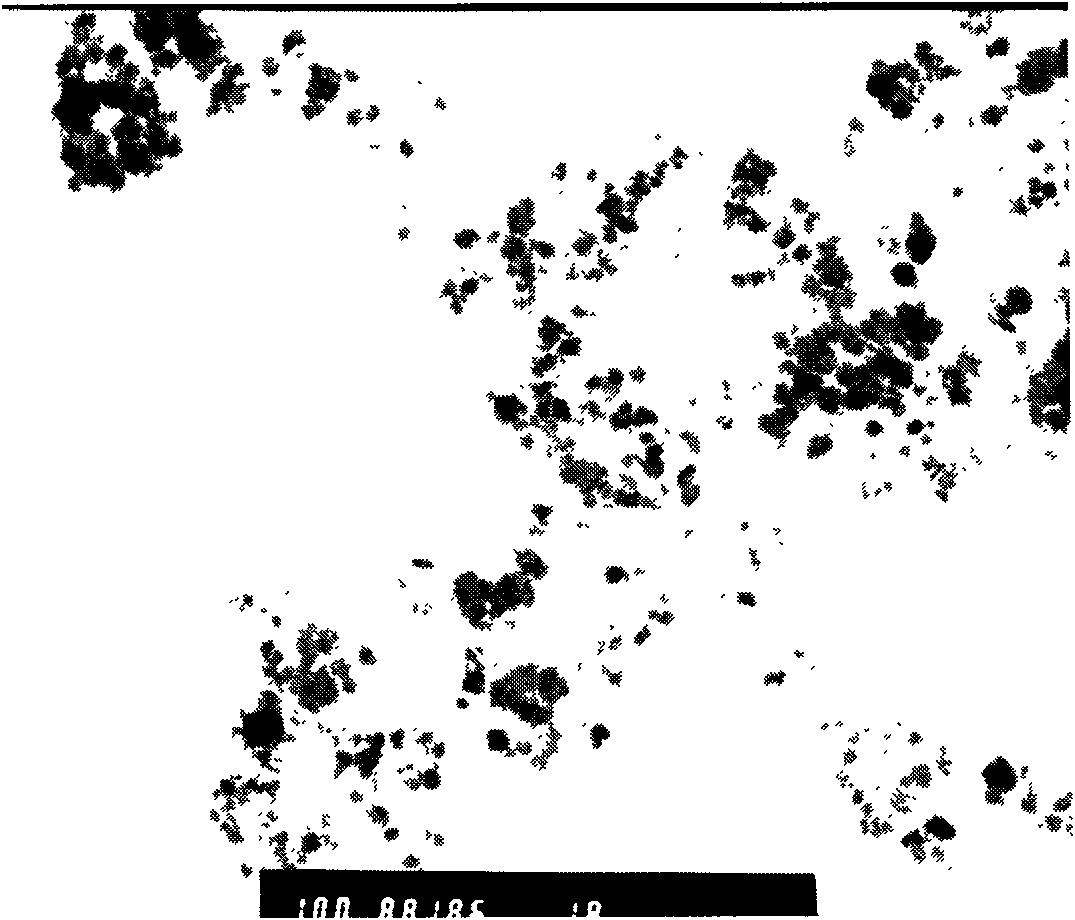

[0034] Step: 1) Add 0.2mmol FeSO 4 , 0.025mmol (CH 2 ) 6 N 4 , 3.75ml of deionized water and 11.25ml of ethylene glycol are mixed uniformly and put into the reaction kettle; 2) Place it in a thermostat and heat it at a constant temperature of 160°C for 6 hours; 3) After cooling, separating and drying, it is prepared Fe 3 O 4 Nano particles. figure 1 Shown is a projected electron micrograph of the sample. It can be seen from the picture that the particles of the sample are relatively uniform, and the particle size is 15±5nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com