Method for preparing carbon foam material from biomass tar

A technology of foamed carbon and biomass, which is applied in the field of foamed carbon material preparation, can solve problems such as complex preparation process, and achieve the effect of simple preparation process, high compressive strength and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take by weighing 10g bamboo tar (Jiangsu Jiangyin Zhongju Agriculture and Forestry Technology Co., Ltd.) and 20g p-methylbenzene by mass ratio 0.5: 1, take by weighing 1.2g p-methylbenzene Sulfonic acid is used as a catalyst, placed in a three-necked flask, heated and stirred under a nitrogen atmosphere, and taken out after a constant temperature of 100°C for 1 hour to obtain a B-stage condensed polycyclic aromatic hydrocarbon resin.

[0022] Take 6g of the above B-stage resin in a beaker, heat it to 90°C, and slowly add 3ml of concentrated HNO after the resin is completely melted 3 Stir continuously until the temperature rises to 120° C., stop heating, take out the product, and grind to obtain oxidized B-stage resin powder.

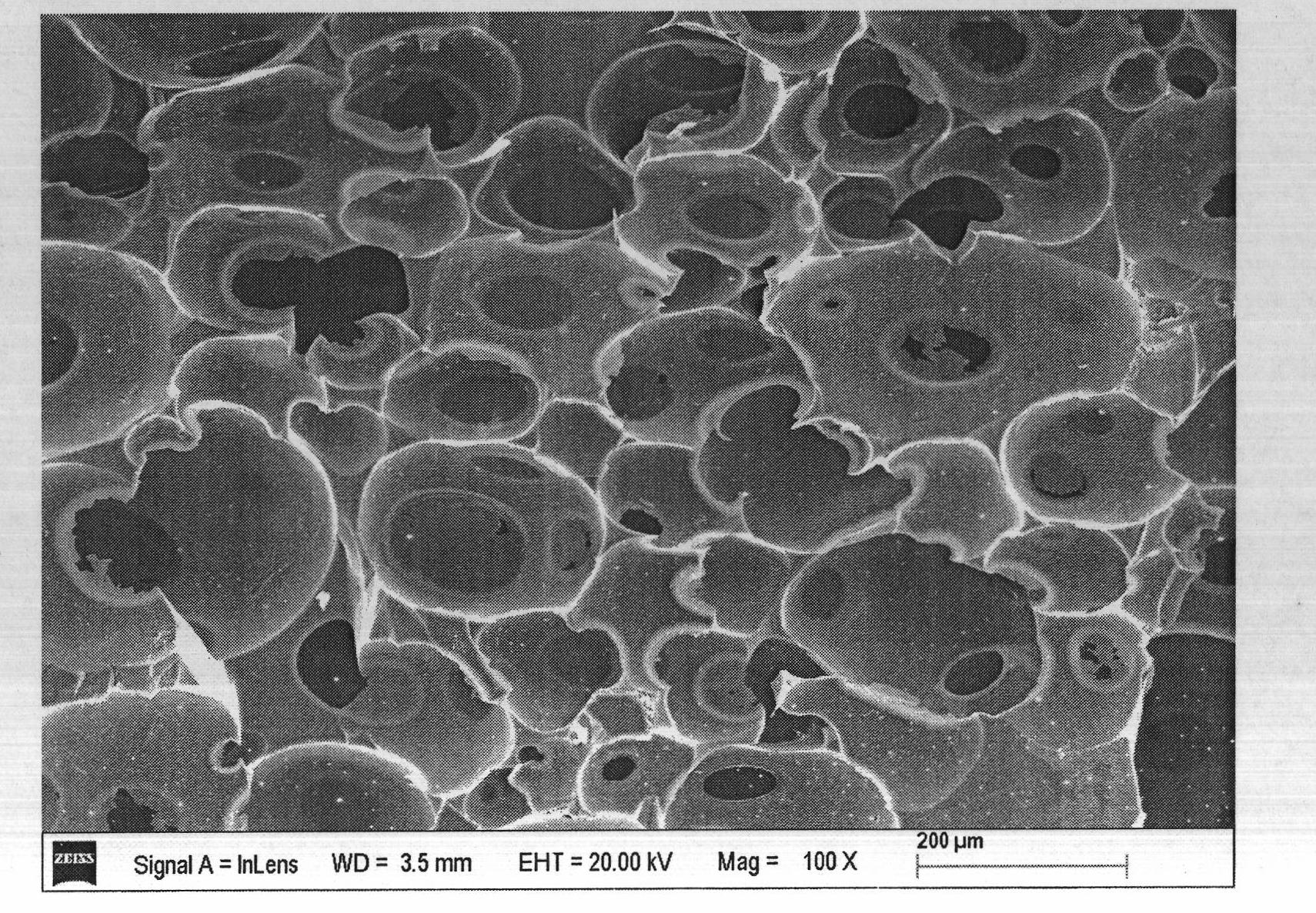

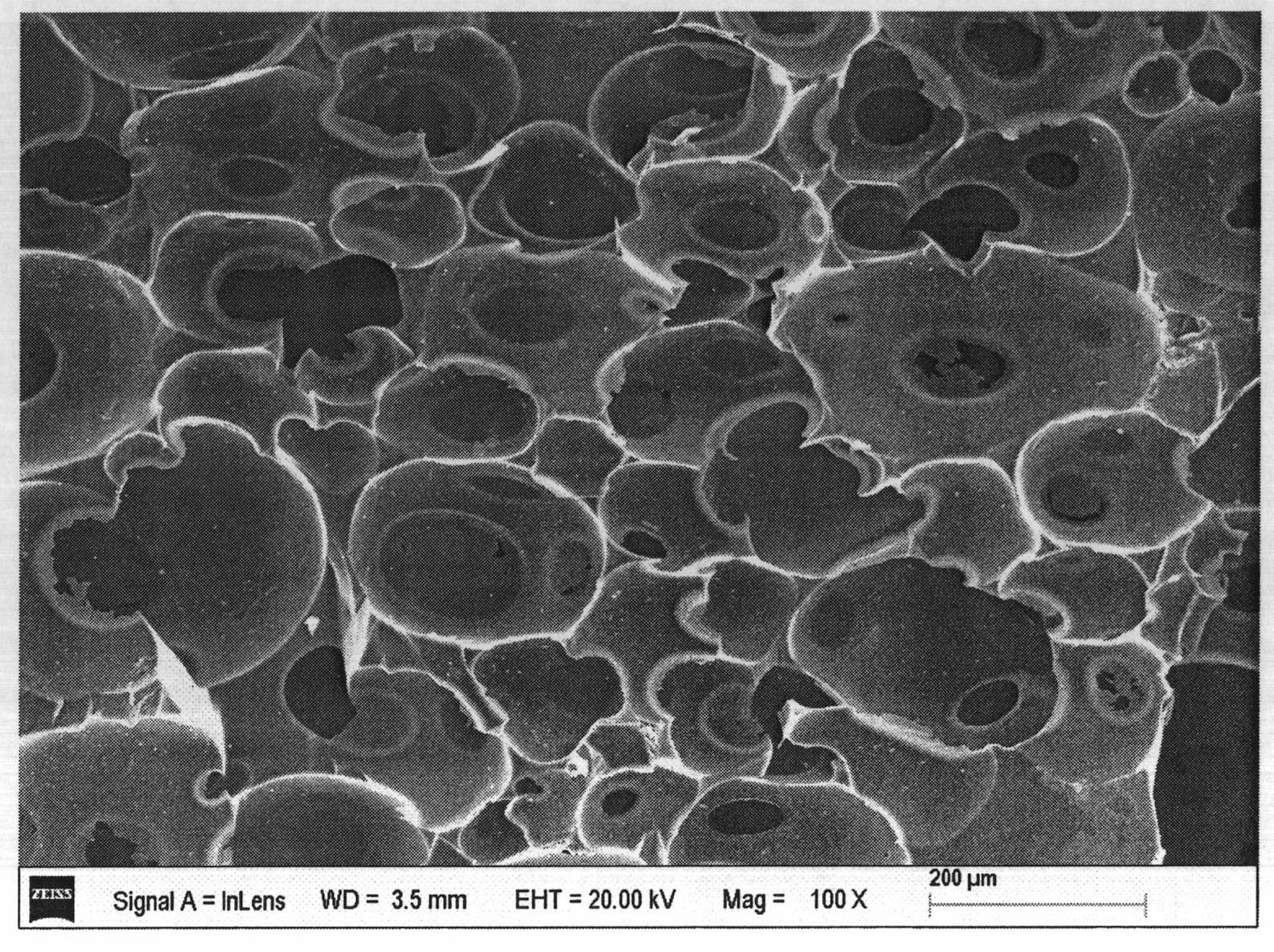

[0023] Put the oxidized B-stage resin powder into a normal-pressure constant-volume mold and shake it tightly, then put it into a muffle furnace at 250°C, keep the temperature constant for 30 minutes, and then cool it out to obtain a foamed resin....

Embodiment 2

[0027] Take by weighing 30g wood tar and 10g terephthalenedimethanol by mass ratio 3: 1, take by weighing 2.4g p-toluenesulfonic acid as catalyst according to the ratio of wood tar and terephthalmic alcohol total mass 6%, place in three-necked flask , heated and stirred under a nitrogen atmosphere, reacted at a constant temperature of 120° C. for 3 hours, and then took it out to obtain a B-stage condensed polycyclic aromatic hydrocarbon resin.

[0028] Take 6g of the above-mentioned B-stage resin in a beaker, heat it to 100°C, and slowly add 2ml of concentrated H after the resin is completely melted. 2 SO 4 Stir continuously until the temperature rises to 140° C., stop heating, take out the product, and grind to obtain oxidized B-stage resin powder.

[0029] Put the oxidized B-stage resin powder into a normal-pressure constant-volume mold and shake it tightly, then put it into a muffle furnace at 300°C, keep the temperature constant for 80 minutes, and then cool it out to obt...

Embodiment 3

[0033] Take by weighing 50g bamboo tar and 10g p-toluene dimethanol by mass ratio 5: 1, take by weighing 5.4g p-toluenesulfonic acid as catalyst according to the ratio of bamboo tar and p-toluene dimethanol total mass 9%, place in three-necked flask , heated and stirred under a nitrogen atmosphere, kept at a constant temperature of 160° C. for 6 hours, and then taken out to obtain a B-stage condensed polycyclic aromatic hydrocarbon resin.

[0034] Take 6g of the above-mentioned B-stage resin in a beaker and heat it to 120°C. After the resin is completely melted, slowly add 4ml of hydrogen peroxide and keep stirring until the temperature rises to 140°C. Stop heating, take out the product, and grind it to obtain oxidized B-stage resin powder .

[0035] Put the oxidized B-stage resin powder into a normal-pressure constant-volume mold and shake it tightly, then put it into a muffle furnace at 400°C, keep the temperature constant for 120 minutes, and then cool it out to obtain a fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com