Combined concentration and smelting method for mixed copper ore

A mixed copper ore dressing and smelting technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve environmental and unscientific problems, achieve short production cycle, high degree of automation, and good foam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

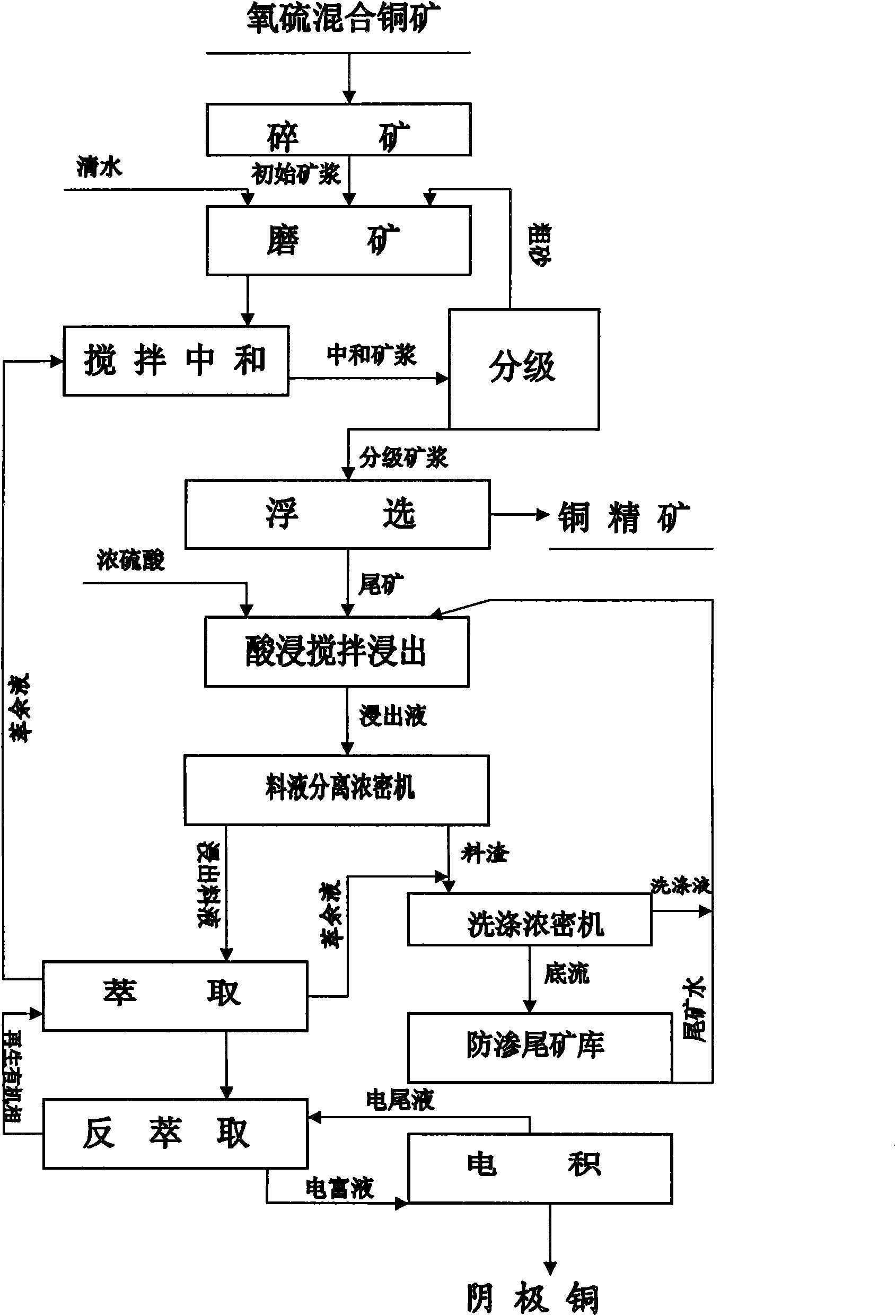

[0012] Such as figure 1 Shown, the production process of the present invention is as follows:

[0013] The oxygen-sulfur mixed copper ore with an oxidation rate between 10% and 80% is subjected to flotation-leaching. The oxygen-sulfur mixed copper ore ore in this embodiment contains 0.96% copper, 3.2% calcium oxide, 0.78% magnesium oxide, and Silicon 66.8%, ferric oxide 2.7%. The copper sulfide minerals in the ore are mainly chalcocite and a small amount of bornite; the copper oxide minerals are mainly malachite, chrysocolla, and a small amount of cuprite. The ore is the sandstone copper mine in central Yunnan, Yunnan. The production scale is 100 tons of ore per day.

[0014] Oxygen-sulfur mixed copper ore is coarsely crushed by PEF400×600 jaw crusher and finely crushed by PEF250×750 jaw crusher into fine ore. The particle size of fine ore is controlled to -20mm, and the fine ore is put into the ore grinding bin. The fine ore is fed into the 1500×3000 ball mill by the ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com