Method for preparing electrochemical biosensor based on horse radish peroxidase-porous zirconium phytate nanoparticle modified glassy carbon electrode

A technology of horseradish peroxidase and biosensor, which is applied in the field of preparation of electrochemical biosensors, can solve the problems of hydrogen peroxide biosensors that have not yet been detected, and achieves low cost, good bio-affinity, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

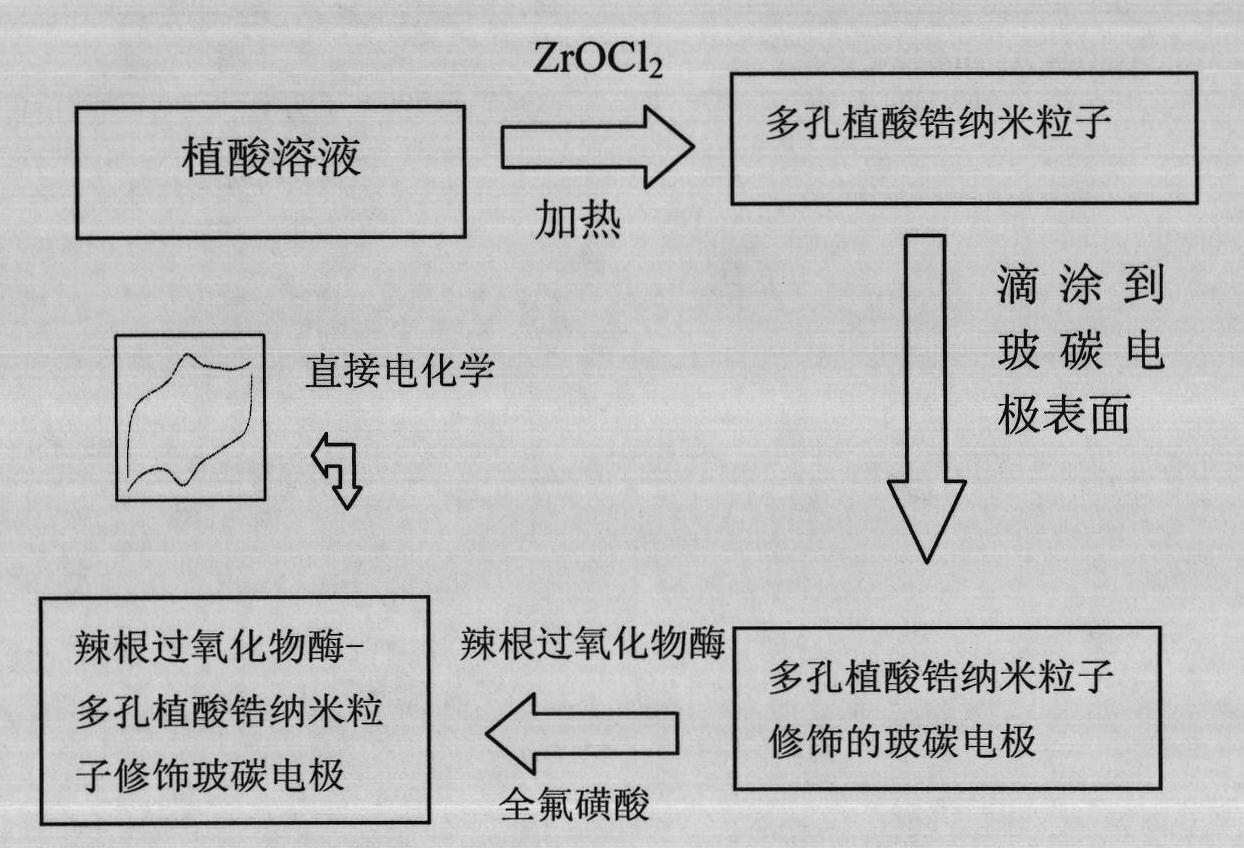

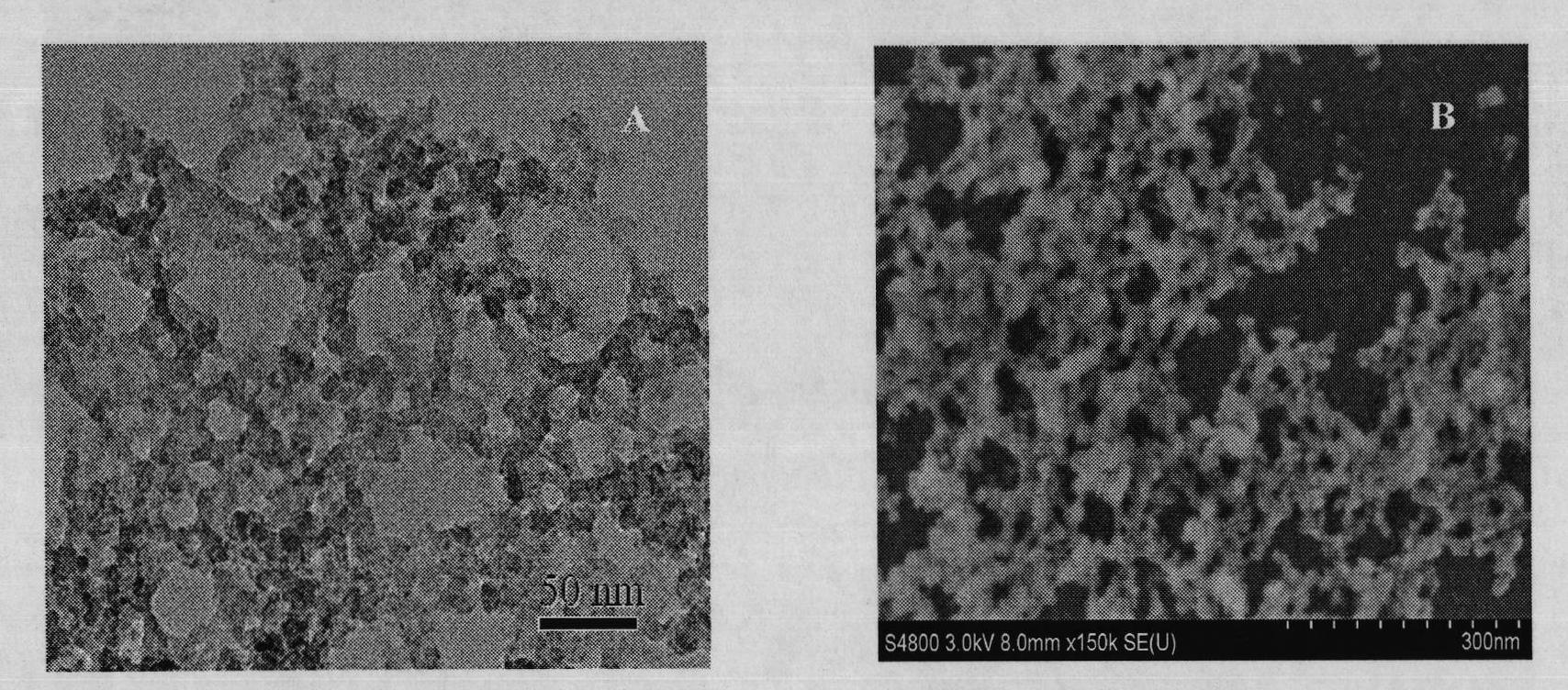

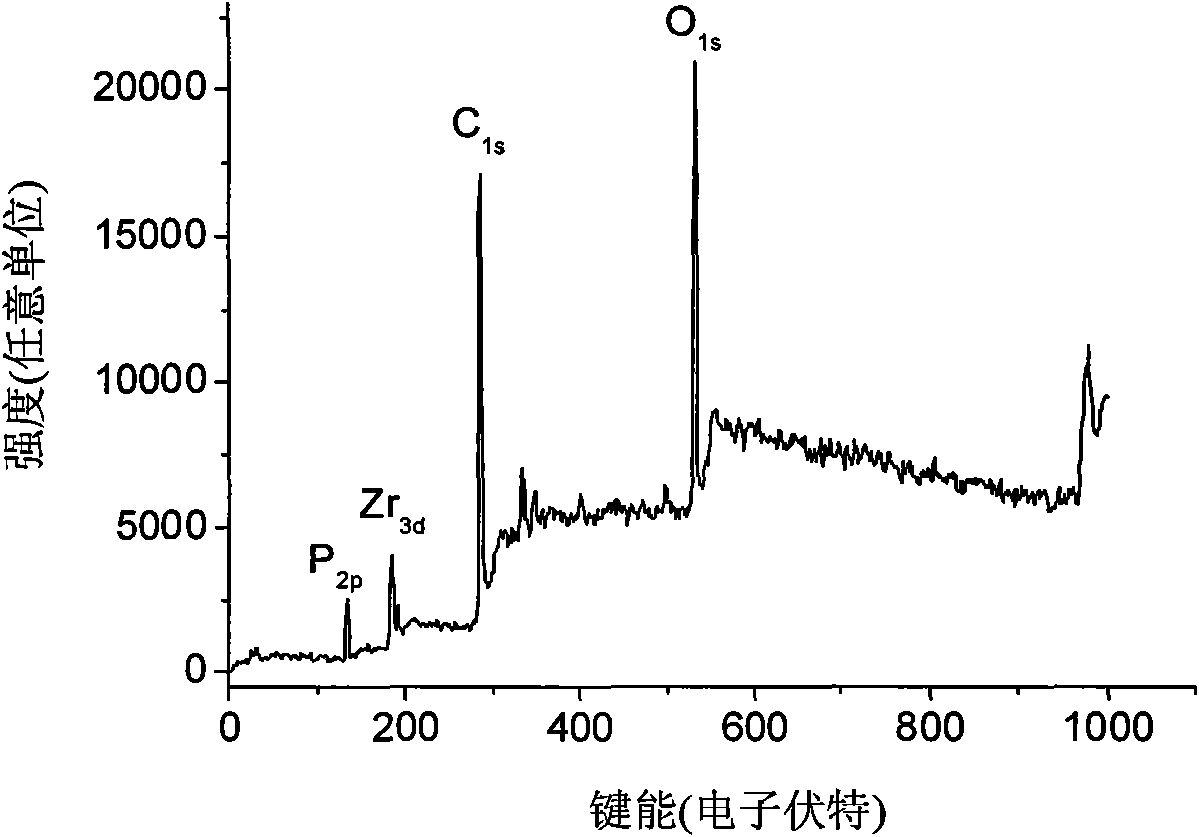

Embodiment 1

[0033] Preparation method of horseradish peroxidase (HRP) biosensor based on porous zirconium phytate nanoparticles: 0.001mol / L ZrOCl 2 Acidic solution, slowly added dropwise to 0.001mol / L sodium phytate solution heated to 90°C under constant stirring (sodium phytate and ZrOCl 2 The volume ratio of the solution is 1:3), and reacted for 1 h. After cooling, centrifuge (7000rpm), wash with ultrapure water (>18MΩ*cm), and then disperse to obtain nanoporous zirconium phytate colloid; take 3 μL of zirconium phytate micellar dispersion and drop it on the inverted clean glassy carbon electrode surface, put it in the refrigerator (4°C) to dry; then drop 3 μL of 5mg / mL horseradish peroxidase (HRP) solution (pH=7.4PBS) onto the glassy carbon electrode modified by nano-zirconium phytate, and put it in the refrigerator Dry it inside (4°C); finally, drop 3 μL of 1% perfluorosulfonic acid (Nafion) solution on the surface of the modified electrode, and put it in the refrigerator (4°C) to dry...

Embodiment 2

[0035]Preparation method of horseradish peroxidase (HRP) biosensor based on porous zirconium phytate nanoparticles: 0.001mol / L ZrOCl 2 Acidic solution, slowly added dropwise to 0.001mol / L sodium phytate solution heated to 80°C under constant stirring (sodium phytate and ZrOCl 2 The volume ratio of the solution is 1:3), and reacted for 1 h. After cooling, centrifuge (6000rpm), wash with ultrapure water (>18MΩ*cm), and then disperse to obtain nanoporous zirconium phytate colloid; take 3 μL of zirconium phytate micellar dispersion and drop it on the inverted clean glassy carbon electrode surface, put it in the refrigerator (4°C) to dry; then drop 3 μL of 5mg / mL horseradish peroxidase (HRP) solution (pH=7.4PBS) onto the glassy carbon electrode modified by nano-zirconium phytate, and put it in the refrigerator Dry it inside (4°C); finally, drop 3 μL of 1% perfluorosulfonic acid (Nafion) solution on the surface of the modified electrode, and put it in the refrigerator (4°C) to dry ...

Embodiment 3

[0037] Preparation method of horseradish peroxidase (HRP) biosensor based on porous zirconium phytate nanoparticles: 0.001mol / L ZrOCl 2 Acidic solution, slowly added dropwise to 0.001mol / L sodium phytate solution heated to 100°C under constant stirring (sodium phytate and ZrOCl 2 The volume ratio of the solution is 1:3), and reacted for 1 h. After cooling, centrifuge (5000rpm), wash with ultrapure water (>18MΩ.cm), and then disperse to obtain nanoporous zirconium phytate colloid; take 3 μL of zirconium phytate micellar dispersion and drop it on the inverted clean glassy carbon electrode surface, put it in the refrigerator (4°C) to dry; then drop 3 μL of 5mg / mL horseradish peroxidase (HRP) solution (pH=7.4PBS) onto the glassy carbon electrode modified by nano-zirconium phytate, and put it in the refrigerator Dry it inside (4°C); finally, drop 3 μL of 1% perfluorosulfonic acid (Nafion) solution on the surface of the modified electrode, and put it in the refrigerator (4°C) to dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com