Manufacture method of electrode of solar battery

The technology of a solar cell and its manufacturing method, which is applied in the field of solar cells, can solve problems such as complex manufacturing, inconvenient operation of replacing targets, poor process adjustability, etc., and achieve the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Figure 4 It is a flow chart of the electrode manufacturing method of the thin film solar cell in the present embodiment, Figure 5 to Figure 6 is a schematic diagram of the method.

[0047] like Figure 4 As shown, the preparation method includes:

[0048] Step S1: Depositing an intrinsic zinc oxide film on the substrate;

[0049] Step S2: Doping the intrinsic zinc oxide film to form a doped zinc oxide film.

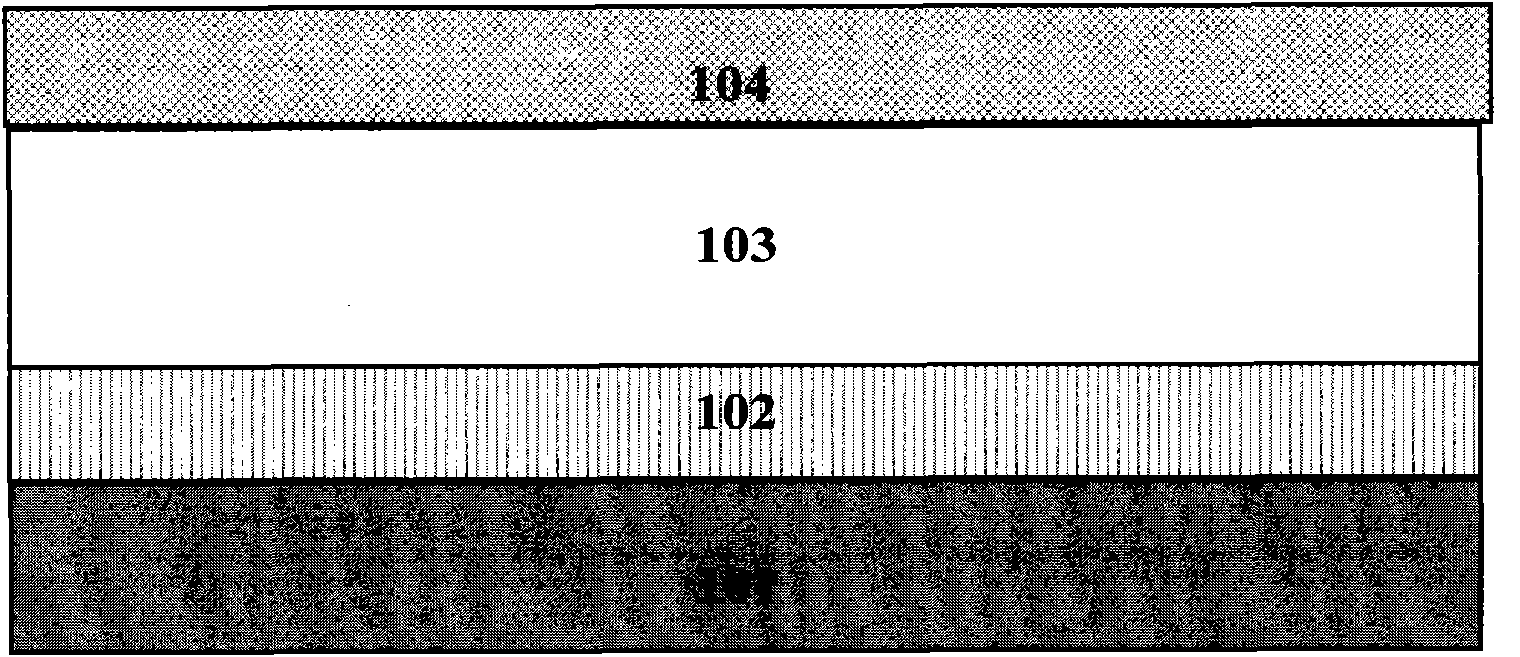

[0050] Specifically, such as Figure 5 As shown, the substrate in this embodiment is a glass substrate 301, and an intrinsic zinc oxide film (without impurities) 302 is deposited on the glass substrate 301 by CVD. The film itself prepared by the CVD method has a certain amount of fluff. The surface 304 can achieve a good suede surface and improve the light-harvesting effect without the need for a suede-making process; then, as Image 6 As shown, the intrinsic zinc oxide film 302 is doped by an ion implantation process or a diffusion process to form a doped ...

Embodiment 2

[0058] Figure 7 It is a flow chart of the electrode manufacturing method of the thin film solar cell in the present embodiment, Figure 8 to Figure 10 is a schematic diagram of the method.

[0059] like Figure 7 Shown, the electrode manufacturing method of described thin-film solar cell comprises:

[0060] Step A1: Depositing an intrinsic zinc oxide film on the substrate;

[0061] Step A2: Texturing the intrinsic zinc oxide film;

[0062] Step A3: Doping the intrinsic zinc oxide film to form a doped zinc oxide film.

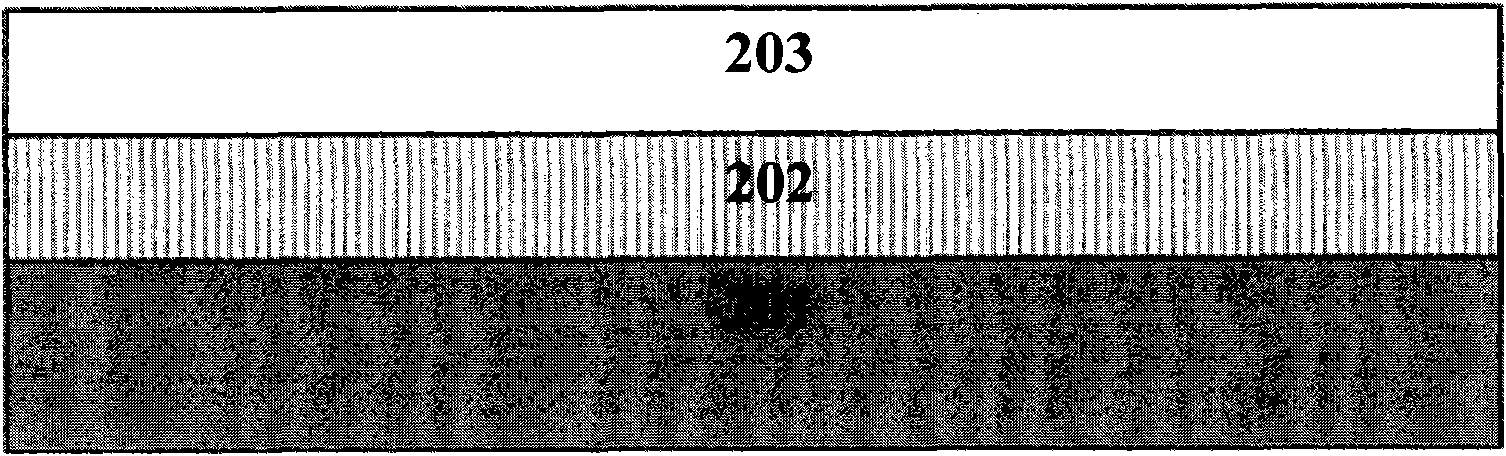

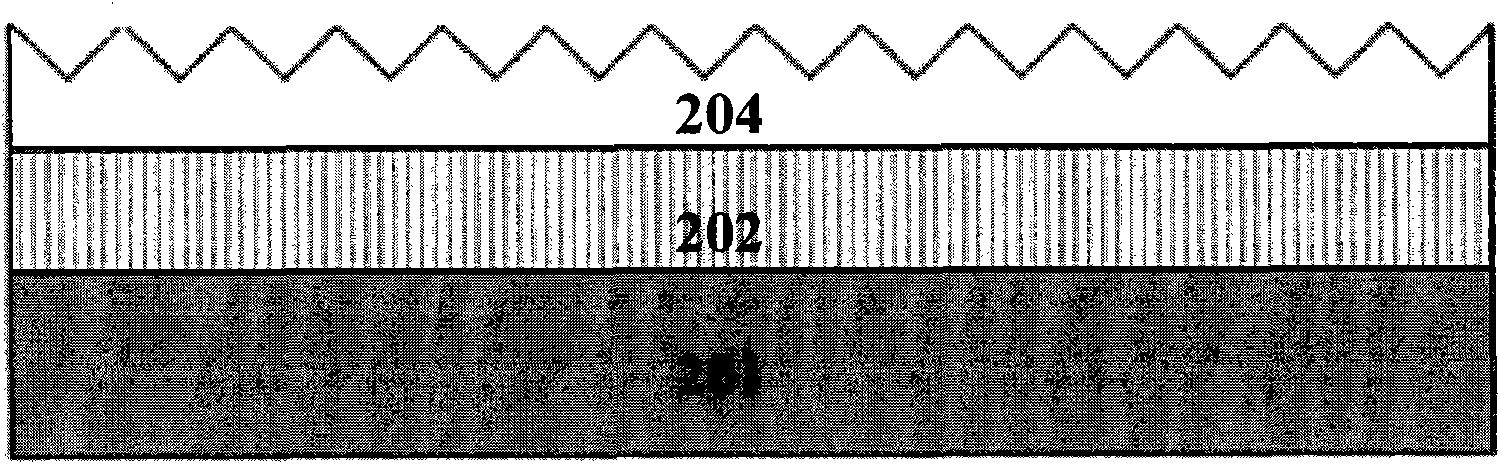

[0063] Specifically, such as Figure 8 As shown, the substrate is a glass substrate 401, and an intrinsic zinc oxide film 402 is deposited on the glass substrate 401 by Physical Vapor Deposition (Physical Vapor Deposition, PVD). The PVD method is, for example, magnetron sputtering. Pure zinc oxide ceramic target; then, as Figure 9 As shown, a uniform textured surface 404 is formed on the surface of the intrinsic zinc oxide film 402 by chemical texturing...

Embodiment 3

[0068] Figure 11 It is a flow chart of the electrode manufacturing method of the thin film solar cell in the present embodiment, Figure 12 to Figure 14 is a schematic diagram of the method.

[0069] like Figure 11 Shown, the electrode manufacturing method of described thin-film solar cell comprises:

[0070] Step B1: forming a barrier layer on the substrate;

[0071] Step B2: depositing an intrinsic zinc oxide film on the barrier layer;

[0072] Step B3: Texturing the intrinsic zinc oxide film;

[0073] Step B4: Doping the intrinsic zinc oxide film to form a doped zinc oxide film.

[0074] Specifically, such as Figure 12 As shown, the substrate is a glass substrate 501, and a barrier layer 502 is formed on the glass substrate. The barrier layer 502 includes one or more of silicon oxide, silicon nitride, and silicon oxynitride, and can be deposited by CVD or PVD. ; then, if Figure 13 As shown, the intrinsic zinc oxide film 503 is deposited on the barrier layer 502 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com