Houttuynin derivative lipid microsphere preparation and preparation method thereof

A technology for houttuyniacin and derivatives, which is applied in the directions of antifungal agents, pharmaceutical formulations, anhydride/acid/halide active ingredients, etc., can solve the problems of hidden safety hazards, multiple side effects, and high prices, and save time and cost. The effect of improving solubility and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

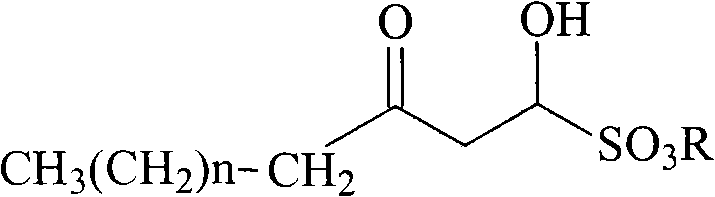

[0056] Example 1. Houttuyfotin derivative lipid microsphere preparation (0.1%):

[0057]

[0058] Preparation Process:

[0059] (1) Dissolve 12g egg yolk lecithin with 100g soybean oil for injection in a water bath at 70°C under nitrogen protection, add 1g houttuydine (I) derivative and 10g vitamin E, heat and stir to dissolve, and obtain oil phase;

[0060] (2) 22.5g glycerol and 5g EDTA were dissolved in 500ml water to obtain the water phase;

[0061] (3) Slowly add the oil phase to the water phase dropwise, at the same time under the protection of nitrogen, shear (shear speed: 10000r / min) for 20min, add water for injection to 1000ml to obtain colostrum, and use sodium hydroxide or hydrochloric acid if necessary Adjust the pH value to about 7.0;

[0062] (4) Under the pressure of 800-900 bar, the colostrum is homogenized by a high-pressure homogenizer for 5-8 times, filtered through a microporous membrane, filled with nitrogen, potted, and sterilized under high pressur...

Embodiment 2

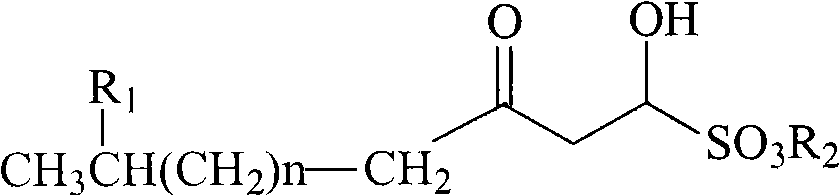

[0063] Example 2, houttuyfonate derivative lipid microsphere preparation (4%):

[0064]

[0065]

[0066] Preparation Process:

[0067] (1) Under 70°C water bath and nitrogen protection, 24g egg yolk lecithin was completely dissolved with 300g soybean oil for injection, 40g houttuyfotin (II) type derivative and 10g vitamin E were added, heated and stirred to dissolve, and obtained oil phase;

[0068] (2) 22.5g glycerol and 5g EDTA were dissolved in 500ml water to obtain the water phase;

[0069] (3) Slowly add the oil phase to the water phase dropwise, at the same time under the protection of nitrogen, shear (shear speed: 10000r / min) for 20min, add water for injection to 1000ml to obtain colostrum, and use sodium hydroxide or hydrochloric acid if necessary Adjust the pH value to about 7.0;

[0070] (4) Under the pressure of 800-900 bar, the colostrum is homogenized by a high-pressure homogenizer for 5-8 times, filtered through a microporous membrane, filled with nitro...

Embodiment 3

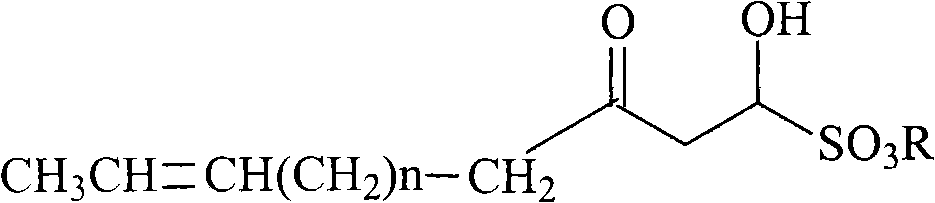

[0071] Example 3. Lipid Microsphere Preparation of Medium and Long Chain Houttuyfondin Derivatives (1%):

[0072]

[0073] Preparation Process:

[0074] (1) Mix 100g of soybean oil for injection and 100g of medium-chain oil for injection in a 70°C water bath and under the protection of nitrogen, and use it to dissolve 24g of egg yolk lecithin, then add 40g of houttuyfonate (III) derivatives and 10g of vitamin E, heated and stirred to dissolve to obtain an oil phase;

[0075] (2) 22.5g glycerol and 5g EDTA were dissolved in 500ml water to obtain the water phase;

[0076] (3) Slowly add the oil phase to the water phase dropwise, at the same time under the protection of nitrogen, shear (shear speed: 10000r / min) for 20min, add water for injection to 1000ml to obtain colostrum, and use sodium hydroxide or hydrochloric acid if necessary Adjust the pH value to about 7.0;

[0077] (4) Under the pressure of 800-900 bar, the colostrum is homogenized by a high-pressure homogenizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com