Preparation method of solid-phase extraction column by utilizing salbutamol molecular imprinting

A solid-phase extraction column and molecular imprinting technology are applied in the field of preparation of an albuterol molecularly imprinted solid-phase extraction column, and can solve the problems that the preparation method of an albuterol molecularly imprinted solid-phase extraction column has not yet been reported, and can achieve high recovery and reduce matrix. Effect, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a salbutamol molecularly imprinted solid-phase extraction column: mix 100 mg of powdered salbutamol molecularly imprinted polymer with 10 ml of pure methanol, oscillate for 10 minutes and then sonicate for 20 minutes, mix evenly, and transfer it into an empty polypropylene solid-phase extraction column. Block them with membrane gaskets respectively, fill them evenly, and wash them on the column with 20ml of a mixed solution of acetic acid and methanol with a volume ratio of 1:9, then rinse with 10ml of pure methanol, and wash with N 2 Purging to remove methanol, vacuum drying that is.

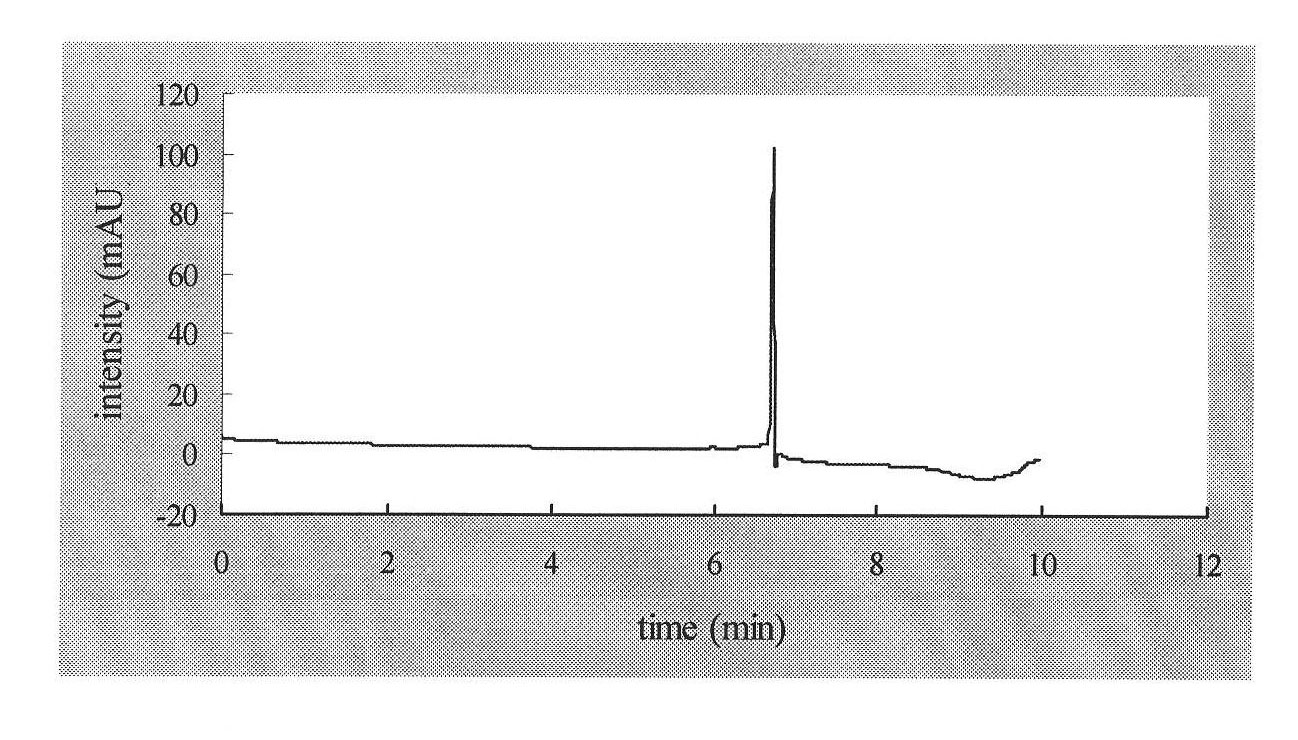

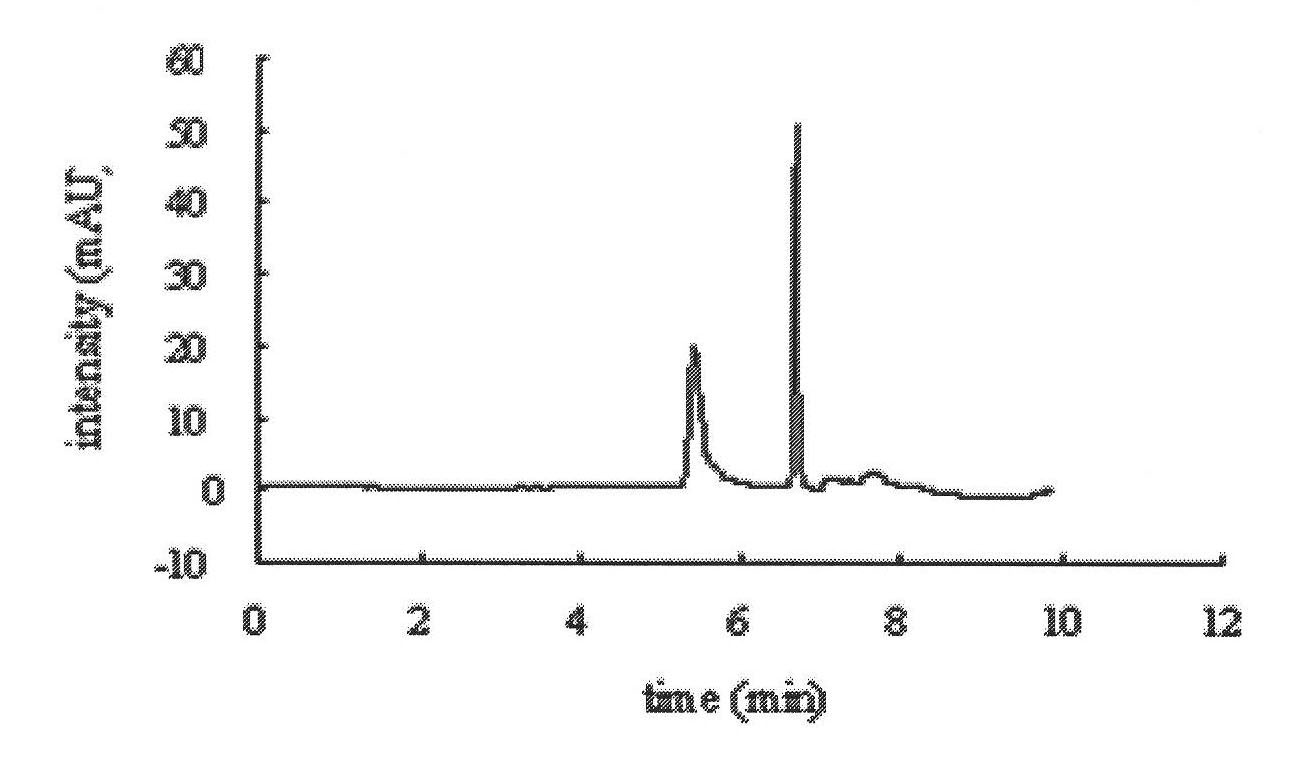

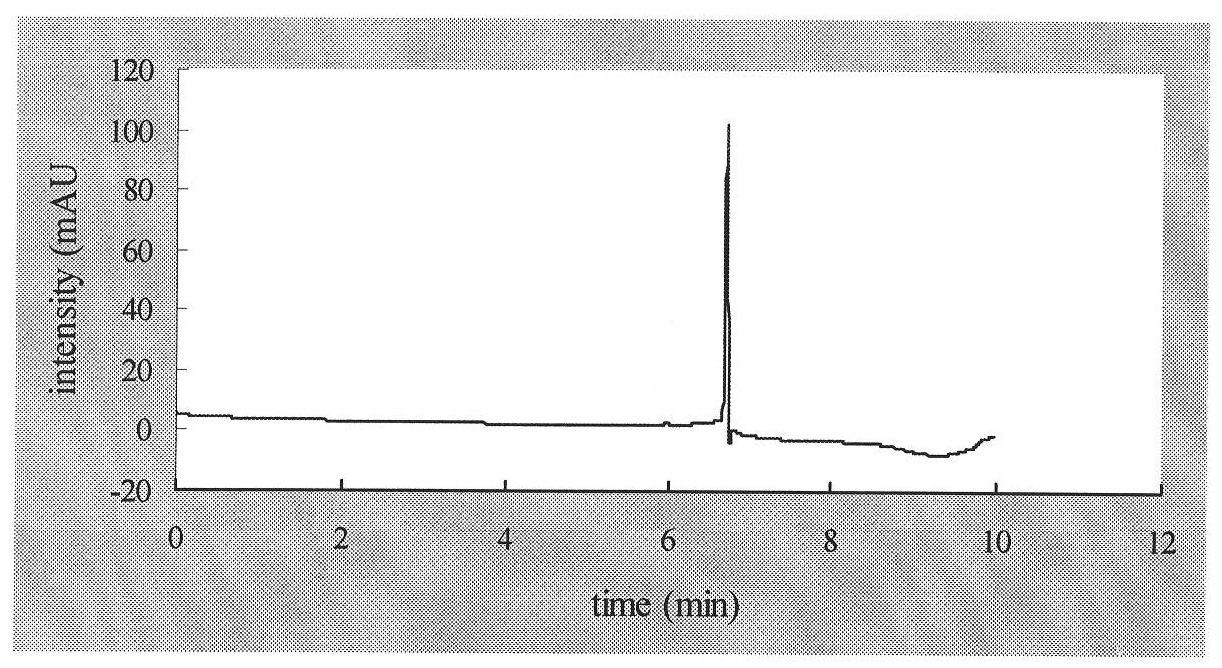

[0020] Evaluation of the solid-phase extraction column: activate the salbutamol molecularly imprinted solid-phase extraction column with 5ml of methanol, then filter 1000ml of river water and load the sample at a flow rate of 1.0ml / min. Rinse with a mixed solution of 5 ml of methanol and water (1:10 by volume), and then elute with a mixed solution of 10 ml of metha...

Embodiment 2

[0022] A preparation method of salbutamol molecularly imprinted solid phase extraction column: mix 500mg of powdered salbutamol molecularly imprinted polymer with 20ml of pure ethanol, oscillate for 20 minutes and then sonicate for 10 minutes, mix evenly, transfer to polypropylene solid phase extraction empty column, and fill evenly After that, use 15ml of a mixed solution of trifluoroacetic acid and methanol with a volume ratio of 1:5 to wash the column several times, then rinse with 20ml of pure ethanol, and use Ar to remove the ethanol, and then dry it.

[0023] After the molecular imprinted solid phase extraction column was used 15 times, the recovery rate of albuterol was about 92.7%.

Embodiment 3

[0025] A preparation method of salbutamol molecularly imprinted solid-phase extraction column: mix 300mg of powdered salbutamol molecularly imprinted polymer with 15ml of pure acetonitrile, oscillate for 15 minutes and then sonicate for 15 minutes, mix evenly, transfer to polypropylene solid-phase extraction empty column, and fill evenly Finally, use 50ml volume ratio of formic acid and methanol mixed solution of 1:20 to wash the column several times, then wash with 15ml pure acetonitrile, and wash with N 2 Purging to remove acetonitrile, vacuum drying that is.

[0026] After the molecular imprinted solid phase extraction column was used 15 times, the recovery rate of albuterol was about 93.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com