Plastic flexible packaging film with high obstruction

A flexible packaging film, high barrier technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of high oxygen and water permeability, high cost of packaging material film, short shelf life, etc., to achieve good oil resistance and Chemical properties, extending the shelf life, improving the effect of brittle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

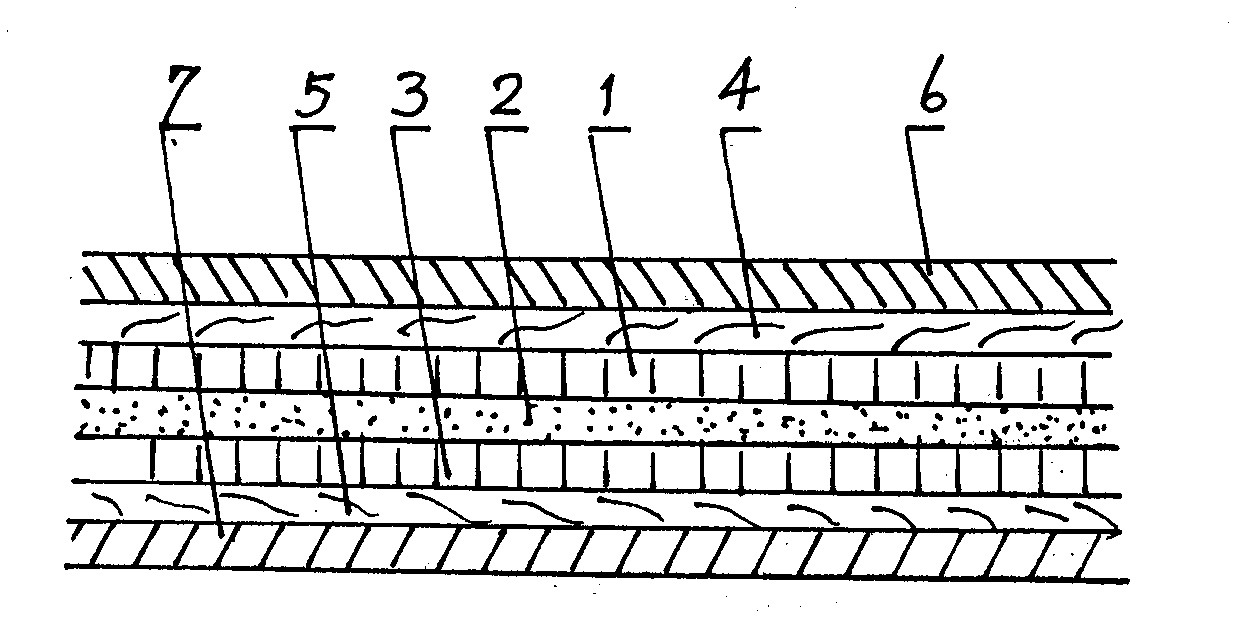

[0008] The high-barrier plastic flexible packaging film provided by the patent application of the present invention is sequentially composed of polyamide PA layer 1, ethylene-vinyl alcohol copolymer EVOH barrier layer 2 and polyamide PA layer 3 as core structural layers, and then a core structural layer The side is a high-barrier plastic flexible packaging film made of the adhesive layer 4 and the heat-sealing layer 6 in a molten state, co-extruded and welded in a die, and the biggest advantage of the ethylene-vinyl alcohol copolymer EVOH barrier layer is The gas barrier effect is superior, but because of the hydroxyl group in the molecular structure of the ethylene-vinyl alcohol copolymer EVOH, it also has hydrophilicity and hygroscopicity. In this technical solution, the ethylene-vinyl alcohol copolymer EVOH has two layers with A polyamide PA layer with good affinity is wrapped in the middle, which greatly improves the barrier properties, gas barrier properties and moisture b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com